Bending plate and method for producing the same

A manufacturing method and technology of bending boards, applied in the field of plywood, can solve the problems of unsightly appearance, waste of resources, and time-consuming use of plywood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

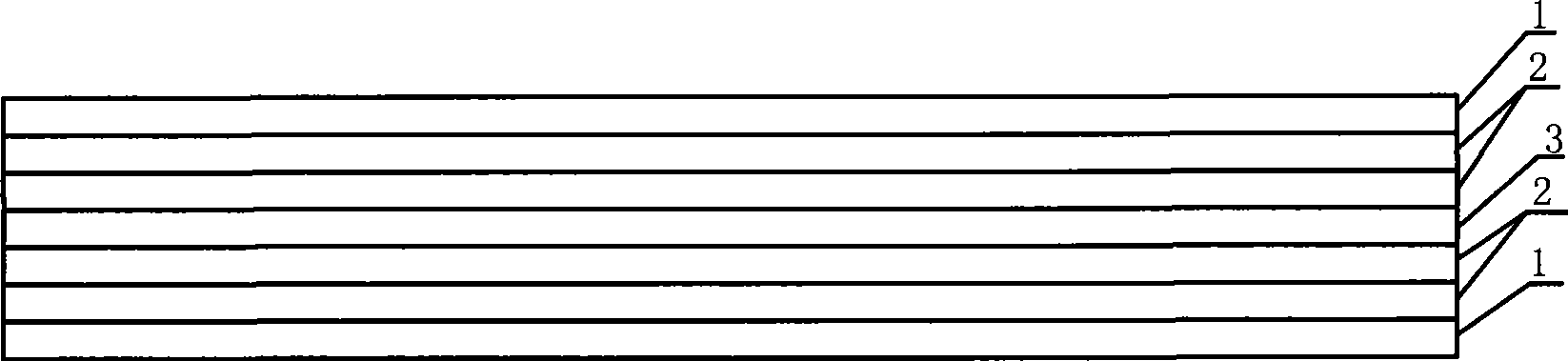

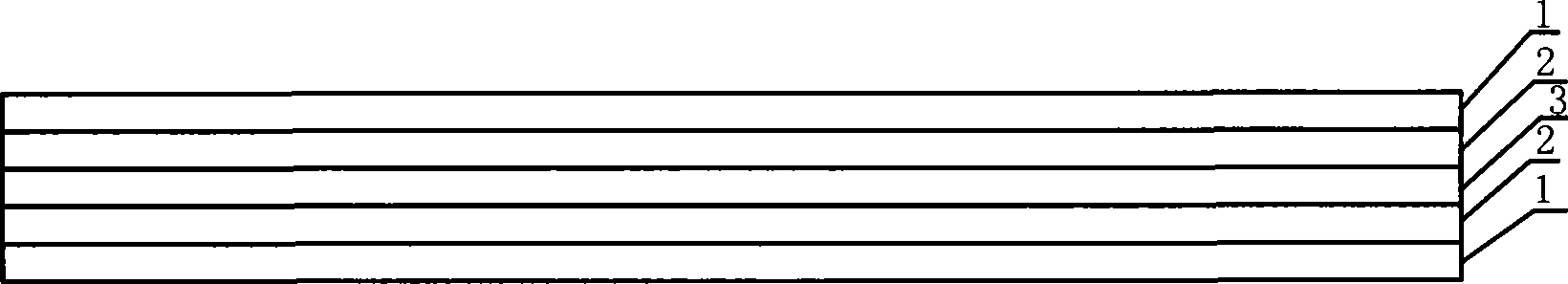

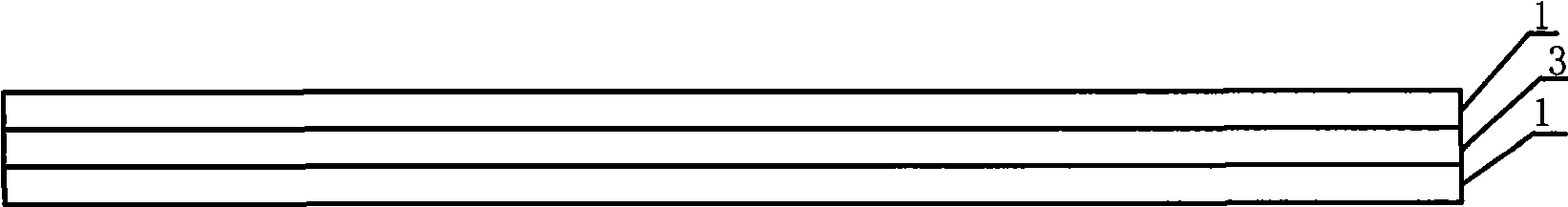

[0026] As shown in the figure, a curved plate of the present invention is composed of a panel 1 and a middle panel 3. The panel 1 is arranged on the upper and lower sides of the middle panel 3, and the wood fiber lines of the panel 1 and the middle panel 3 are distributed crosswise. The panel 1 and the middle panel 3 One or more layers of core boards 2 are arranged in cooperation with each other, or no core board is provided, and the wood fiber texture of the core board 2 is the same as that of the panel 1 . The curved board of the present invention can be divided into a horizontal curved board and a long curved board. Distributed along the length direction (also can be veneer of any specification), the transverse curved plate is bent in the width direction, and the wood fiber grains of the long surface curved panel 1 and core plate 2 are distributed along the direction of length (also can be veneer of any specification), and the middle Board 3. The wood fiber grains are distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com