Self-discharging vehicle cargo box

A technology of dump trucks and cargo boxes, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, and vehicles used for freight, etc. It can solve the problems of knocking off the rear door, deformation and damage of the rear door, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

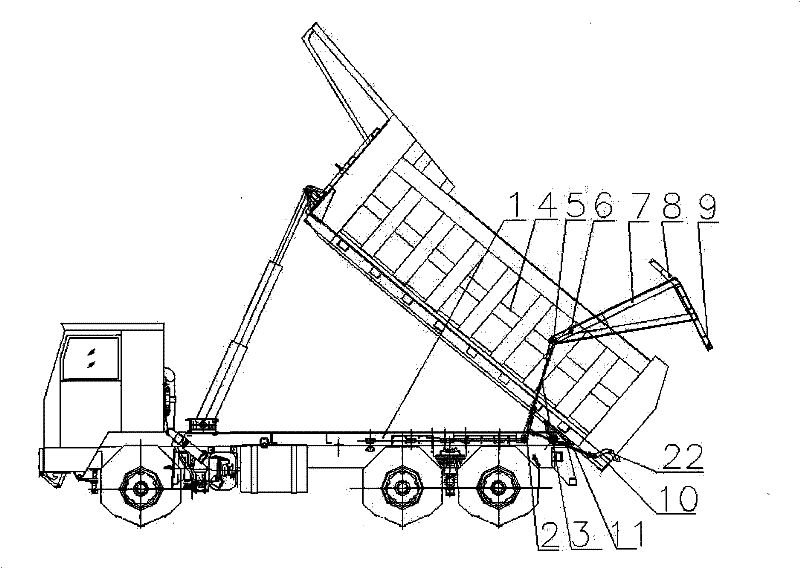

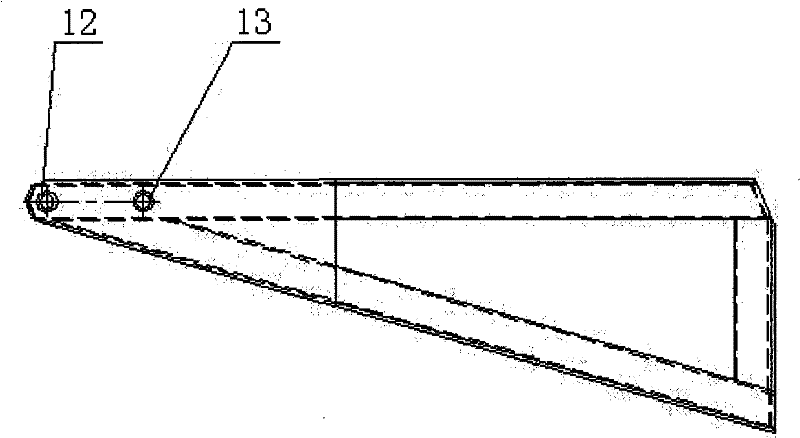

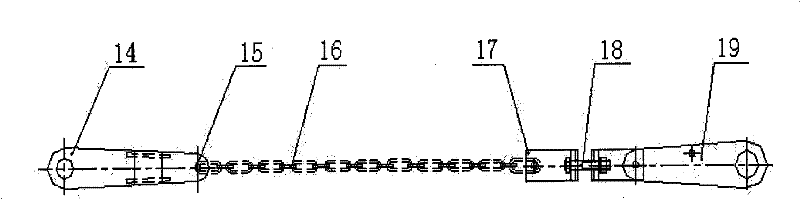

[0011] see Figure 1-Figure 5 , the present invention comprises casing 4 and rear door. Its key technology is to install a lower seat beam 2 connected with the longitudinal beam of the auxiliary frame and perpendicular to the rear part of the subframe 1. The lower seat beam 2 is to weld the lower seat beam shaft 24 at the two ends of the shaped steel beam 23; Body 4 rear portion both sides are welded triangle plate rear axle 6 respectively, triangle plate rear axle sleeve 13 is installed on the triangle plate rear axle 6, triangle plate 7 is installed on the triangle plate rear axle sleeve 13, back door 8 is welded between the front ends of two triangle plate 7, The tail end of the triangle plate 7 is installed with the triangle plate front axle 5, the triangle plate front axle sleeve 12 is installed on the triangle plate front axle 5, the triangle plate front axle sleeve 12 is connected with the lower seat beam 2 by the slide fastener 3, and the slide fastener 3 is at the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com