Miniature narrow gage single switch

A narrow-gauge, miniaturized technology, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of unreliable track tips, no frogs, and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

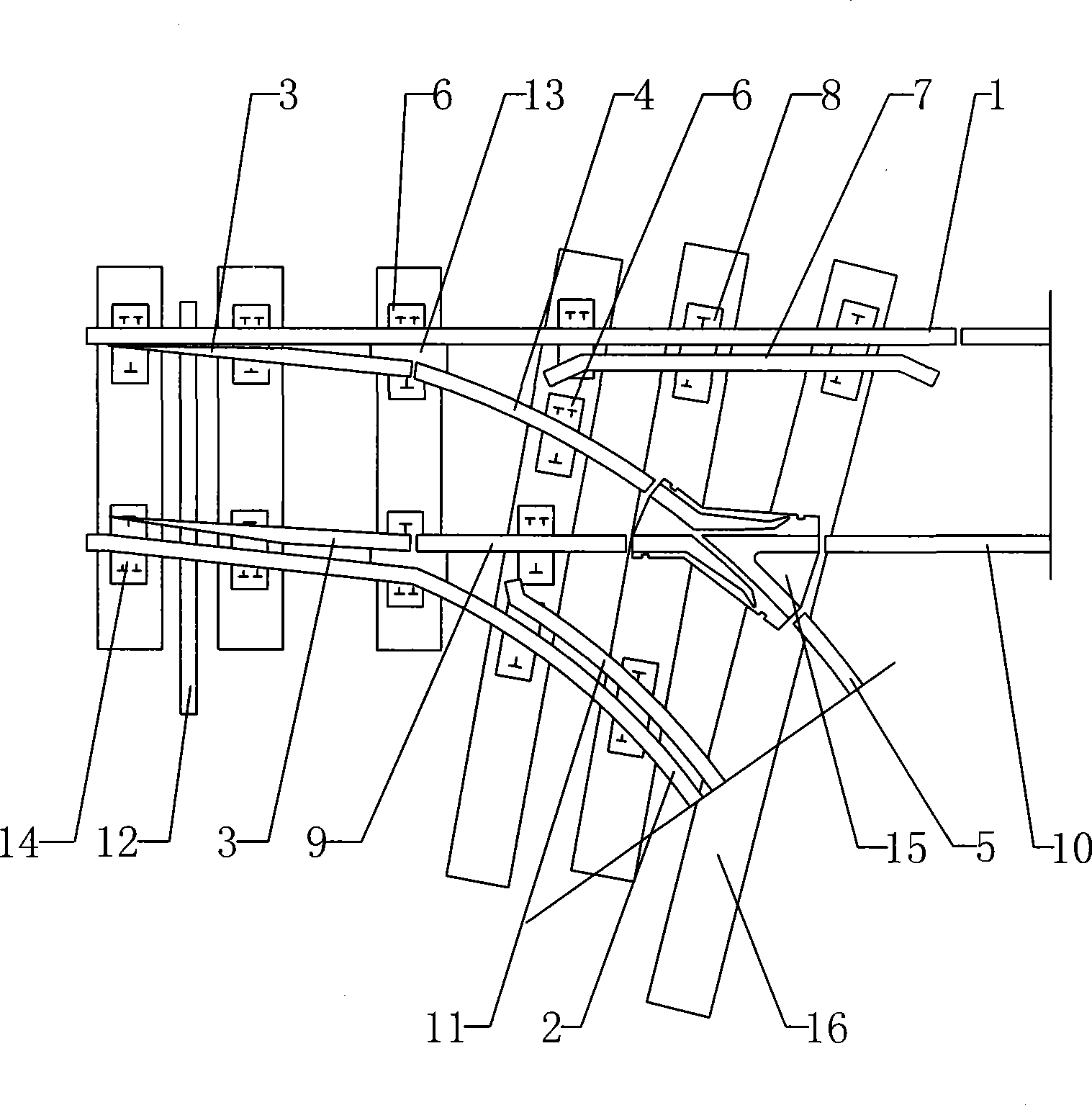

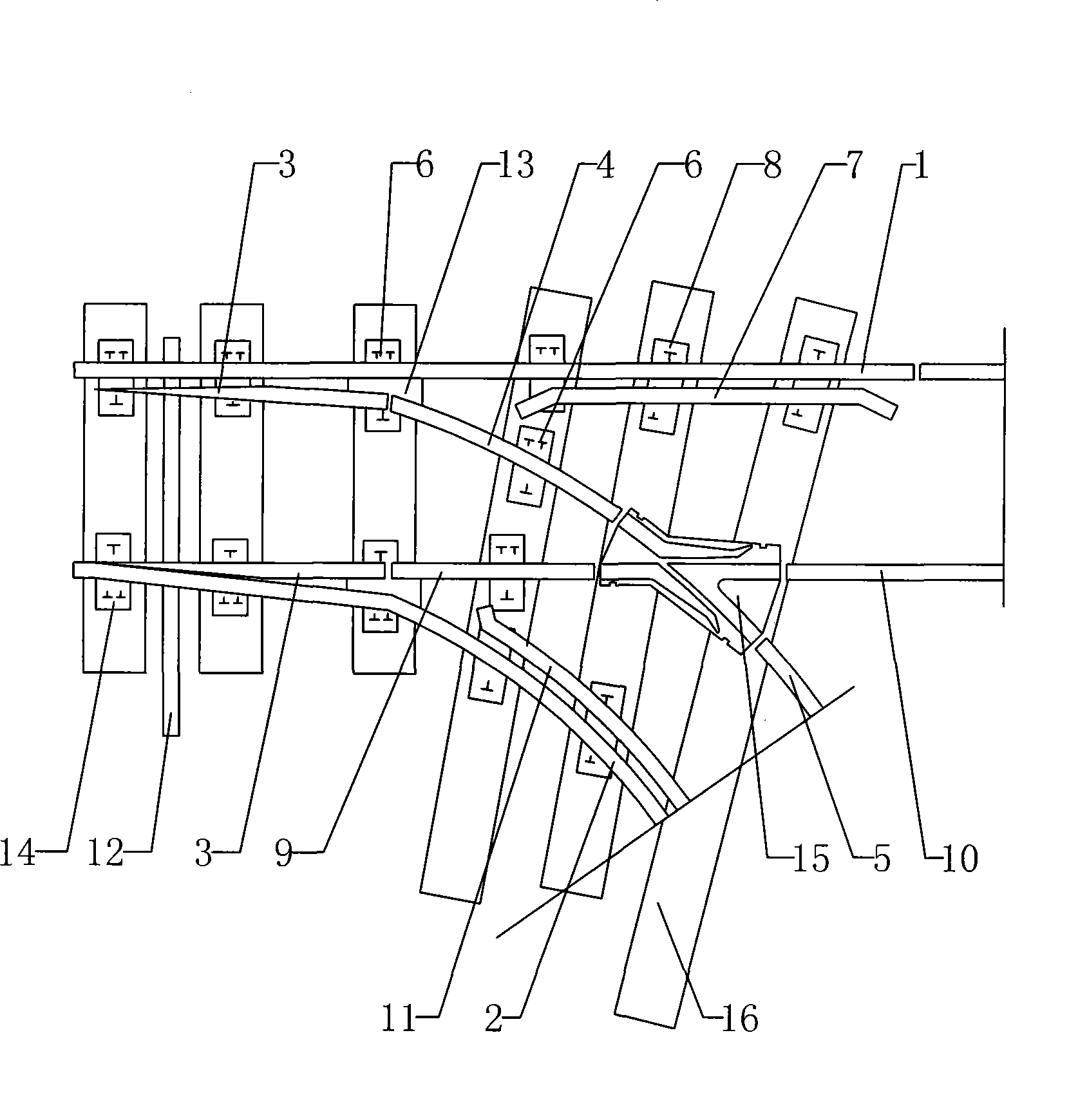

[0012] Such as Figure 1-2 As shown, a miniaturized narrow-gauge single-opening turnout according to the present invention includes a straight basic rail 1 and a curved basic rail 2. One side of the straight basic rail 1 is provided with a switch rail 3, and the switch rail 3 is connected through a curved rail. The connecting rail 4 and the frog 1 are connected with the outer curved rail 5, wherein the curved connecting rail 4 and the frog 15 are fixed on the follower pad 6, and one side of the straight basic rail 1 is provided with a straight guard rail 7, and the straight guard rail 7 is fixed on the two-hole backing plate 8, and one side of the curved basic rail 2 is provided with a tip rail 3, and the tip rail 3 is connected to the outer straight rail 10 through a straight connecting rail 9 and a frog 15, wherein the straight connecting rail 9 and The frog 5 is fixed on the backing plate 6, one side of the curved basic rail 2 is provided with a curved guard rail 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com