Single-plunger injection pump for pressure accumulating tube-fuel injection system

A fuel injection system and injection pump technology, which is applied in the direction of fuel injection pumps, fuel injection devices, charging systems, etc., can solve problems such as injection, and achieve the effects of reduced leakage, reasonable cost, and a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

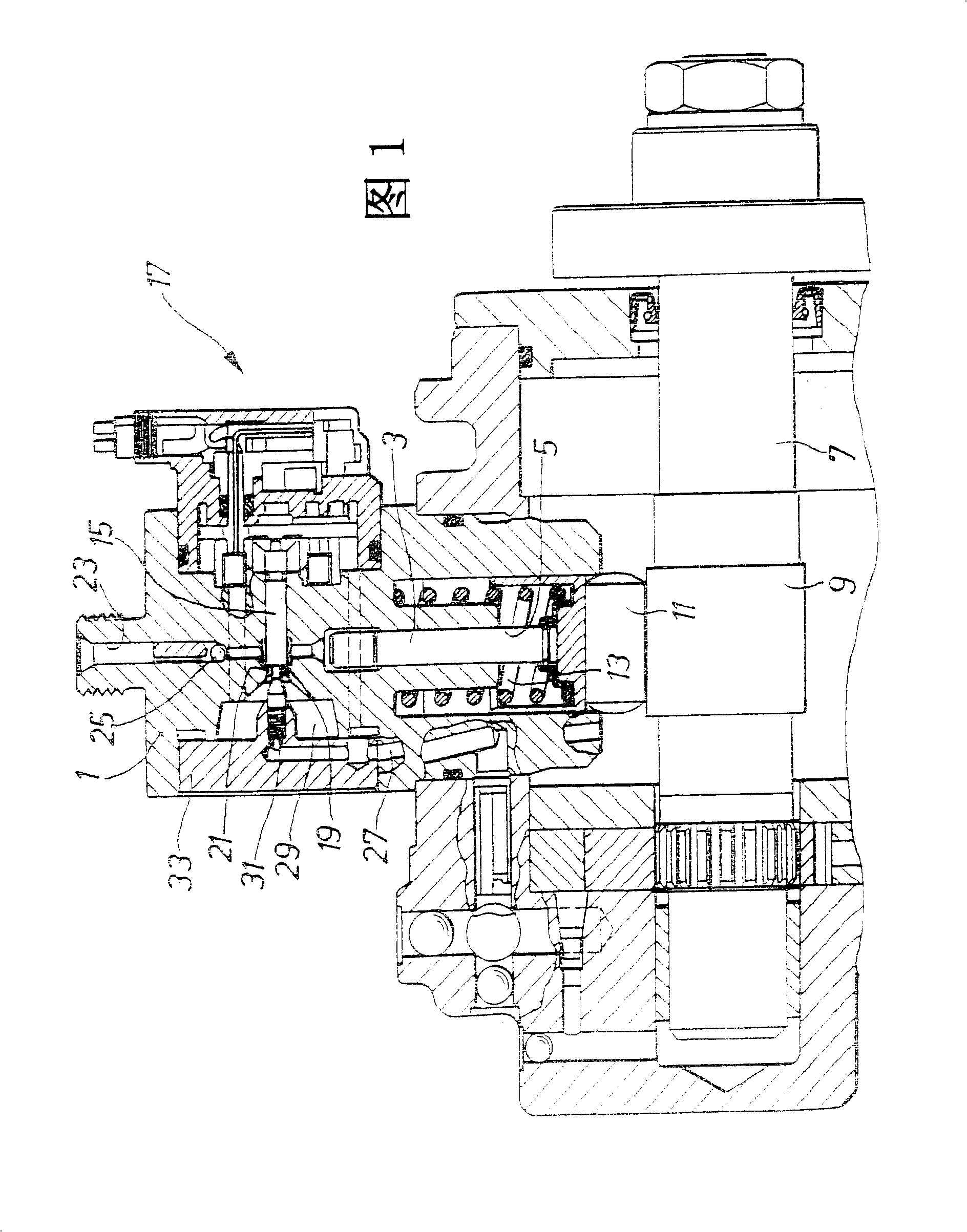

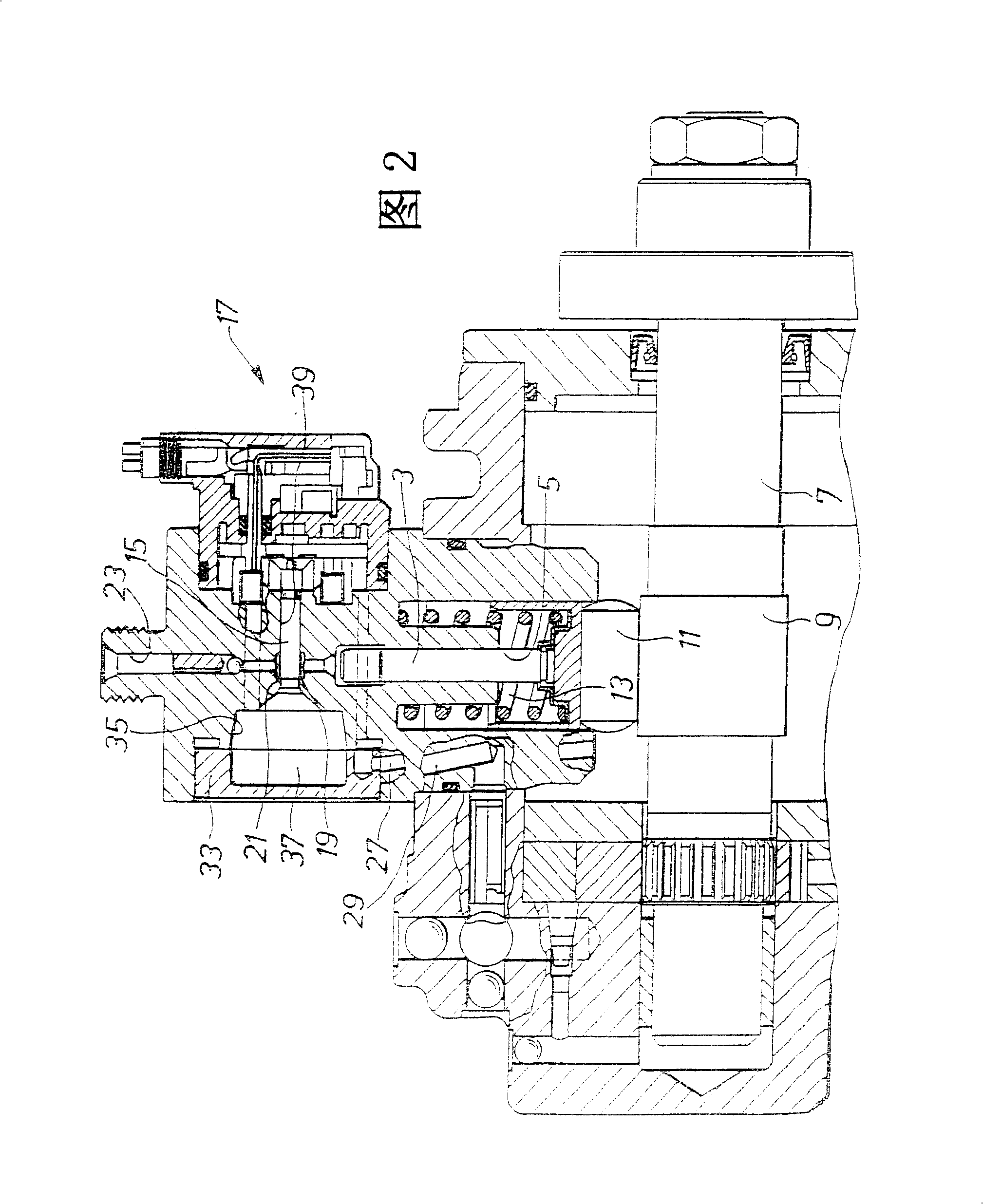

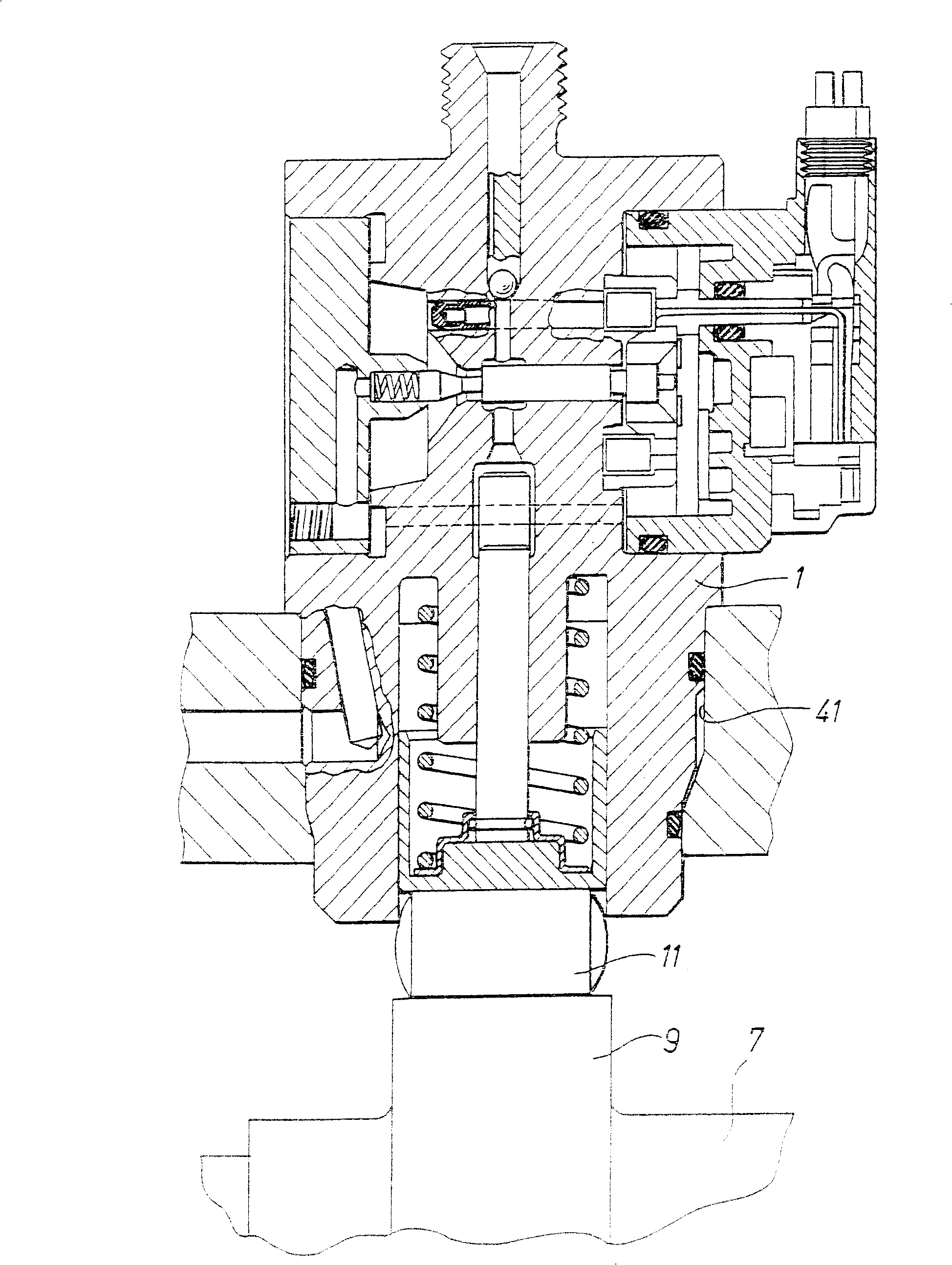

[0025] Figure 1 shows a first embodiment of a single plunger jet pump according to the invention. In a housing 1 a plunger 3 is guided by a pump cylinder 5 . The plunger 3 is driven by a camshaft 7 . An eccentric section 9 of the camshaft 7 acts on the plunger 3 via a push roller 11 . The eccentric section 9 is a cam in the sense of the invention. However, the cam can also have other geometries than an eccentrically arranged circle. The plunger 3 is pressed against the push roller 11 by means of a return spring 13 indicated only schematically.

[0026] Arranged in the housing 1 above the pump cylinder 5 is a control piston 15 as a flow control valve 17 designed as a solenoid valve, which is perpendicular to the longitudinal axis of the pump cylinder 5 . The control piston 15 has a shoulder 19 which forms a sealing seat with a correspondingly formed cam 21 . When the flow control valve 17 is closed, the shoulder 19 seats on the boss 21 and the fuel delivered by the plunger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com