Butt joint control method and apparatus for hydraulic-floating ship elevator

A control method and technology of a ship lift, which is applied to ship lifting devices, ship locks, buildings, etc., can solve the problems of small flow and difficult precise control, and achieve reliable and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

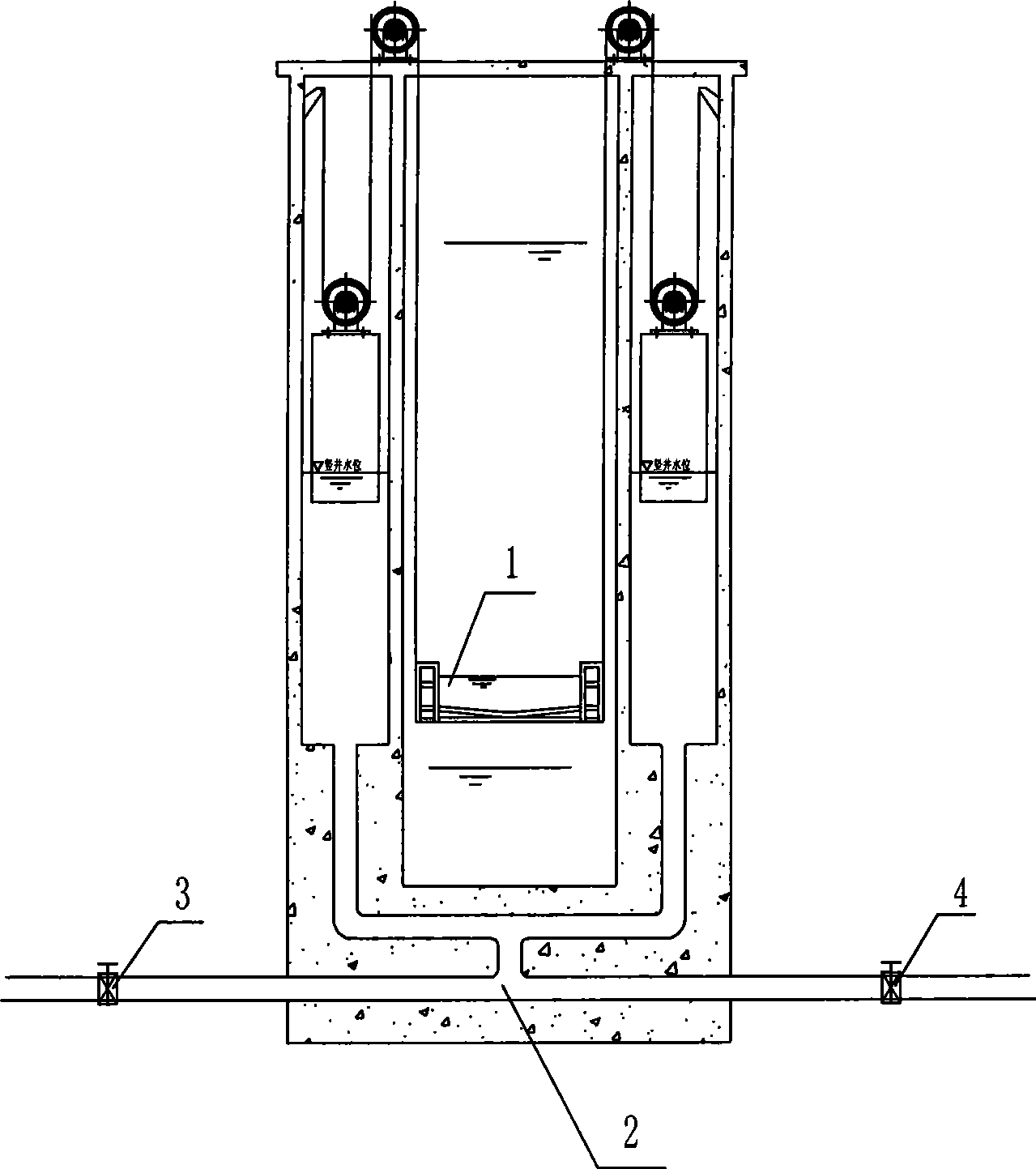

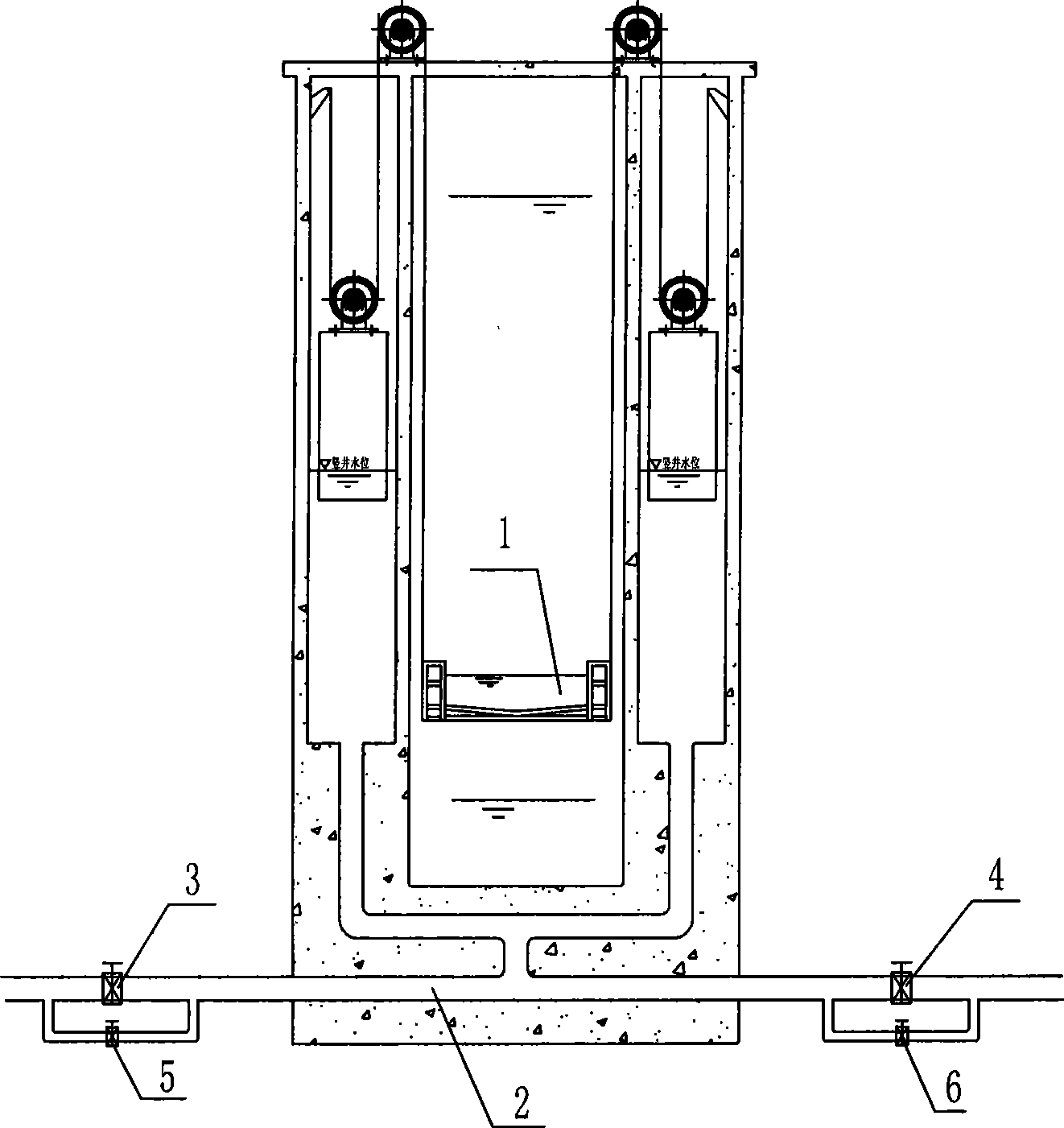

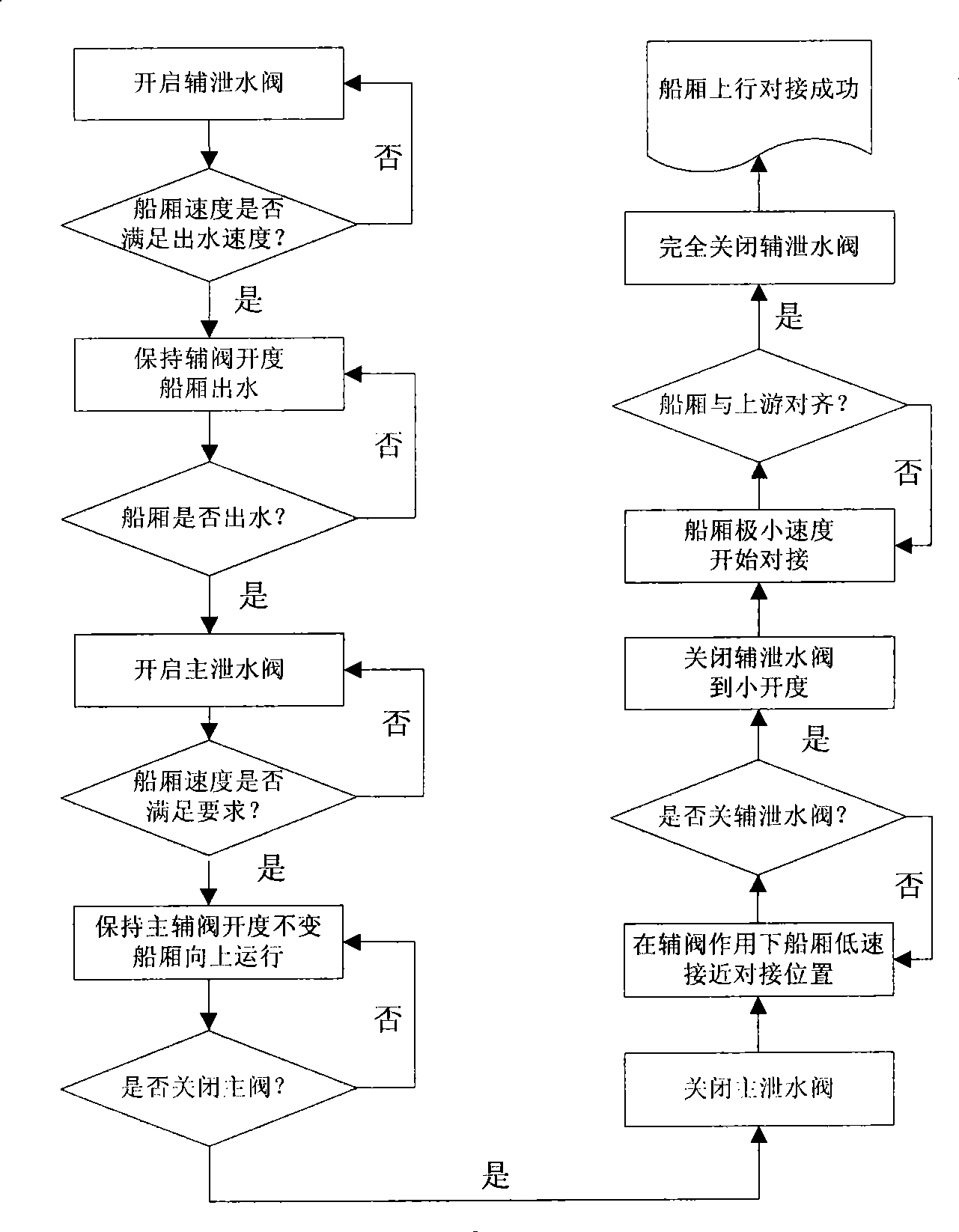

[0019] The operation and docking control method of the hydraulic floating ship lift of the present invention includes the precise docking of the rising operation of the ship receiving box and the precise docking of the descending operation of the ship receiving box. The precise docking process of the rising operation of the ship receiving box is as follows image 3 as shown, Figure 4 It is a schematic diagram of the accurate docking change of the ascending operation of the ship-bearing box, and the precise docking process of the descending operation of the ship-bearing box is as follows: Figure 5 as shown, Figure 6 It is a schematic diagram of the precise docking change of the lowering operation of the bearing box.

[0020] The precise docking of the rising operation of the ship-carrying box is carried out according to the following steps: (1) Open the auxiliary drain valve; (2) Determine whether the speed of the ship-carrying car meets the water outlet speed, if so, proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com