Nozzle pipe integrated electric spraying valve with centrifugal nozzle

A technology of centrifugal nozzles and pump nozzles, which is applied in the direction of fuel injection devices, engine components, machines/engines, etc., which can solve the problems of high cost, high fuel consumption and pollution, and low fuel injection accuracy, so as to prolong the service life and reduce fuel consumption , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

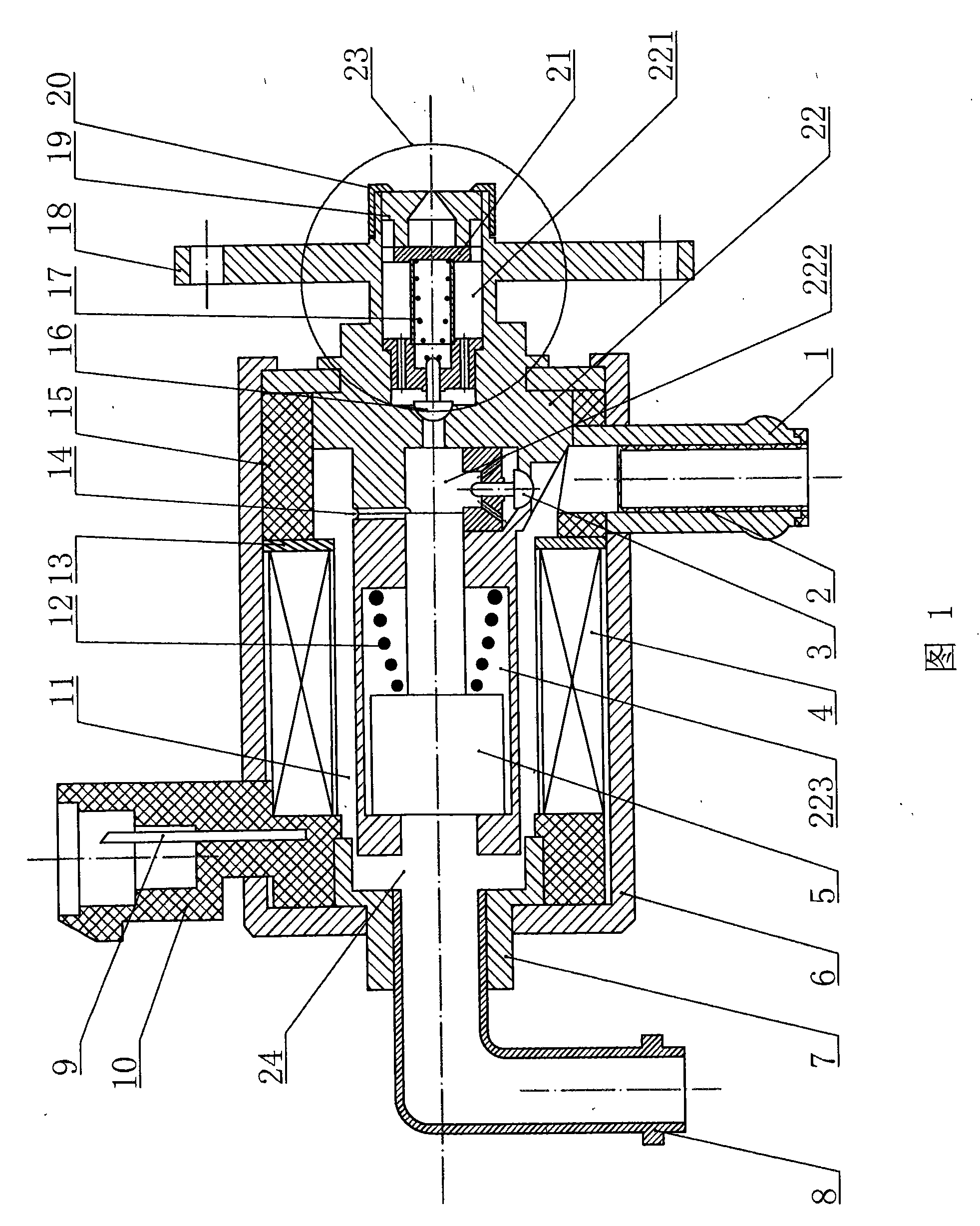

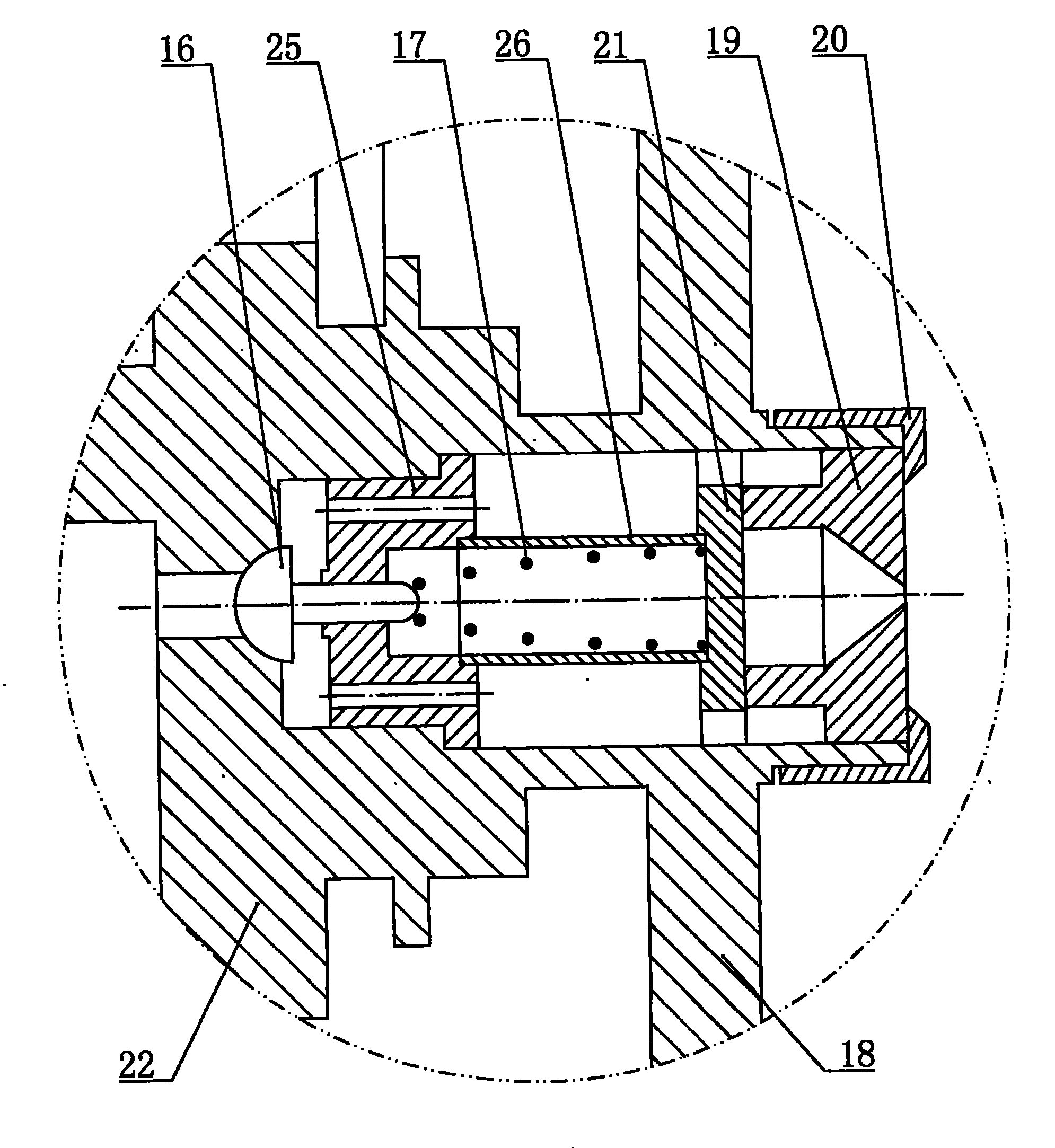

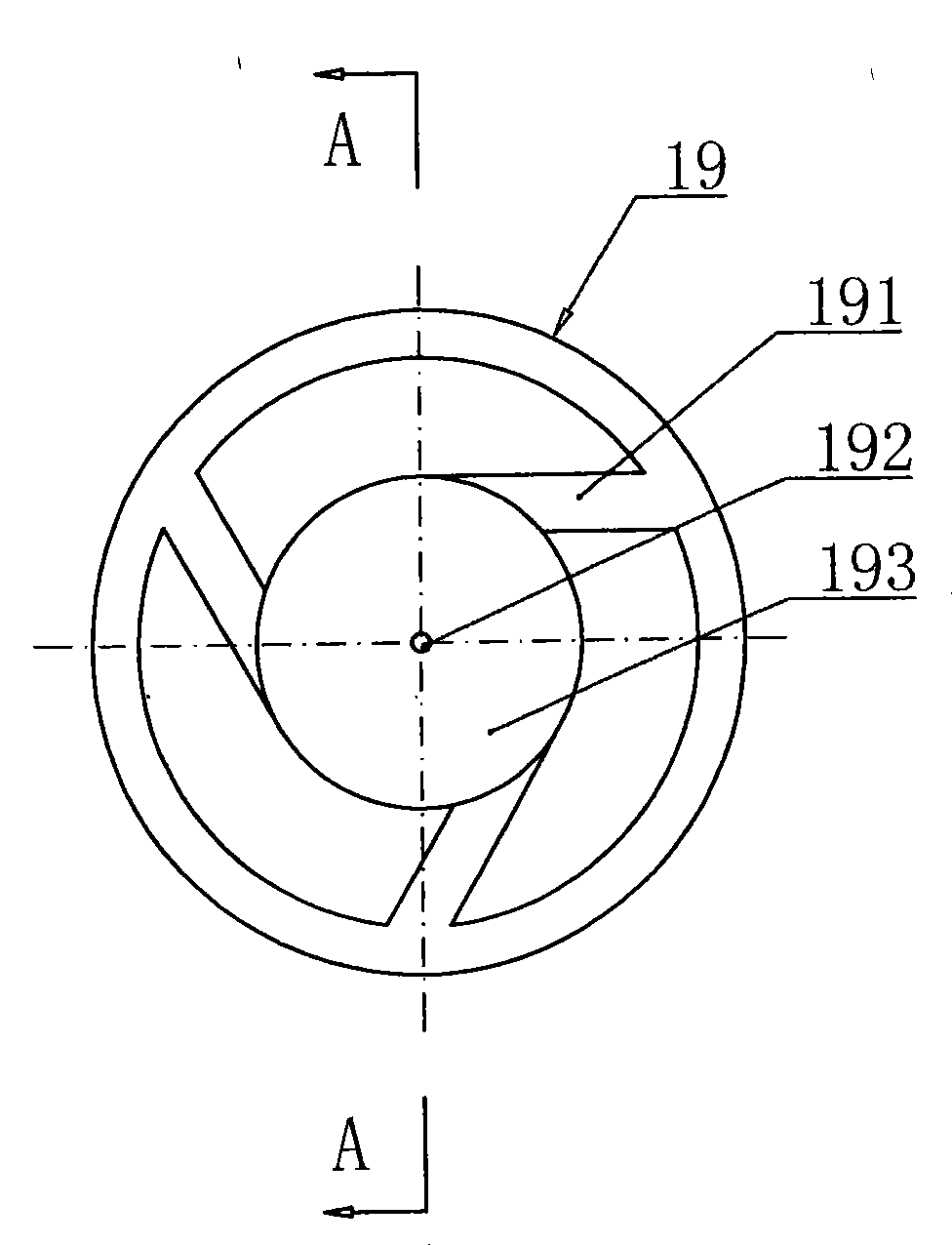

[0015] Such as figure 1 As shown, the present invention comprises shell 6, driving coil 4, driving plunger 5, valve body 22 and centrifugal nozzle assembly 23, and the inside of cylindrical shell 6 is equipped with driving coil 4, and the central hole of this driving coil 4 is equipped with Valve body 22, the front end of the valve body 22 (note: the following front and rear correspond to figure 1 Right and left in the middle) extend out the front end of shell 6 and be provided with mounting plate 18 at extension end. A front cavity 221, a hollow cavity 222 and a rear cavity 223 are respectively provided at the front, middle and rear of the valve body 22, and a centrifugal nozzle assembly 23 is housed in the front cavity 221, and on the side of the hollow cavity 222 The wall is provided with an exhaust hole 14 communicating with the outside and a one-way oil inlet valve 3 communicating with the oil inlet pipe 1 on the side of the housing. The diameter of the rear cavity 223 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com