Smoke discharging system with automatic air draft speed regulation function according to smog concentration

A smoke exhaust system and automatic adjustment technology, which can be used in ventilation systems, heating and ventilation control systems, heating and ventilation safety systems, etc., and can solve problems such as automatic adjustment of suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

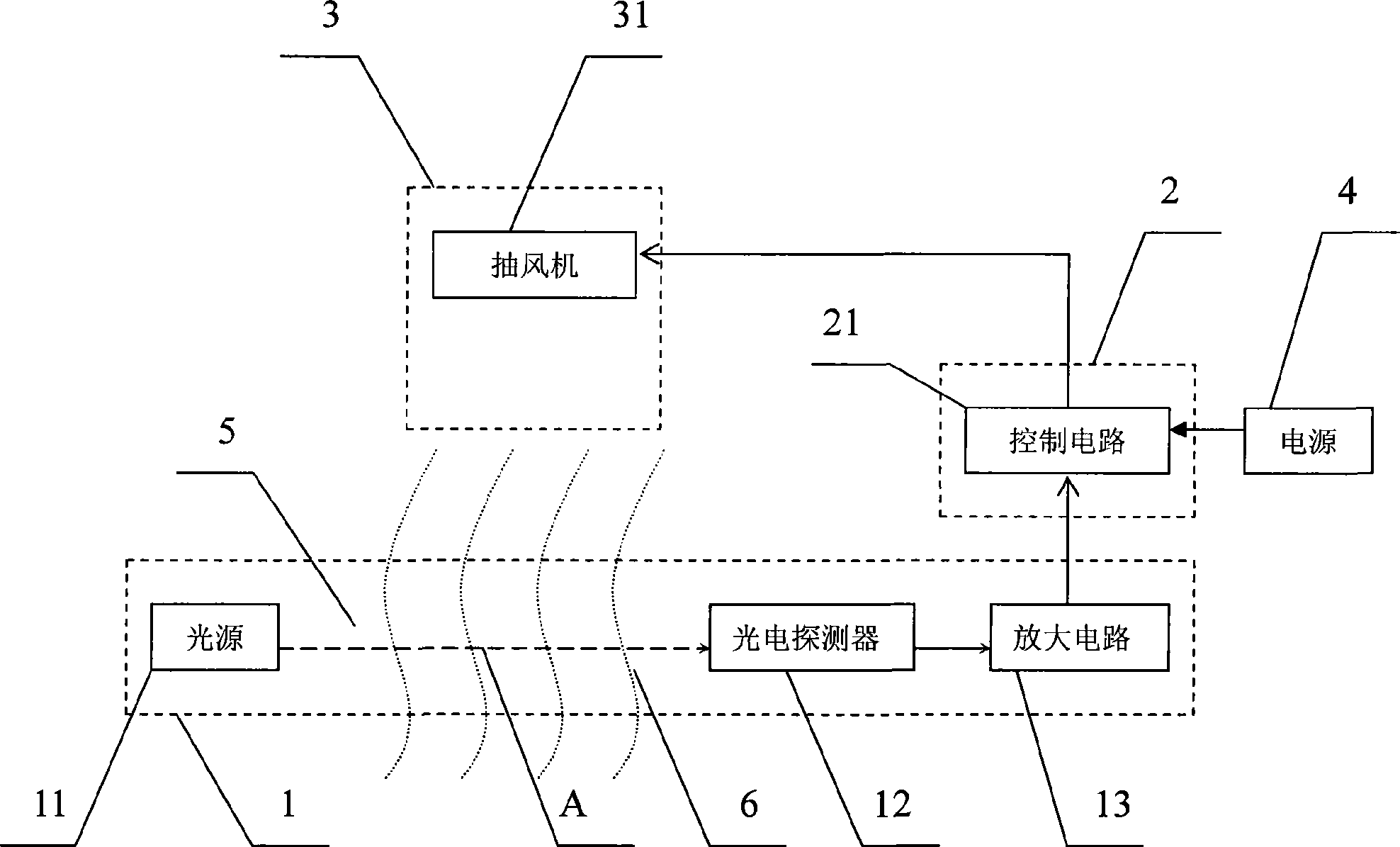

[0031] A smoke exhaust system that can automatically adjust the wind speed according to the smoke concentration, including a photoelectric detection unit 1, a fan speed control unit 2, an exhaust device 3 and a power supply 4, the output end of the photoelectric detection unit 1 is connected to the fan speed control unit 2, and the fan speed The control unit 2 is connected with the ventilation device 3 and the power supply 4 .

[0032]The photodetection unit 1 includes a light source 11, a photodetector 12, and an amplifying circuit 13 whose magnification matches the photodetector 12. There is a space 5 between the light source 11 and the photodetector 12, and the smoke 6 passes through the space 5 to reach the ventilation device 3. The light beam A generated by the light source 11 is consistent with the photodetector 12 in spectral characteristics; the photodetector 12 is connected to the amplifier circuit 13, the light beam A generated by the light source 11 passes through th...

Embodiment 2

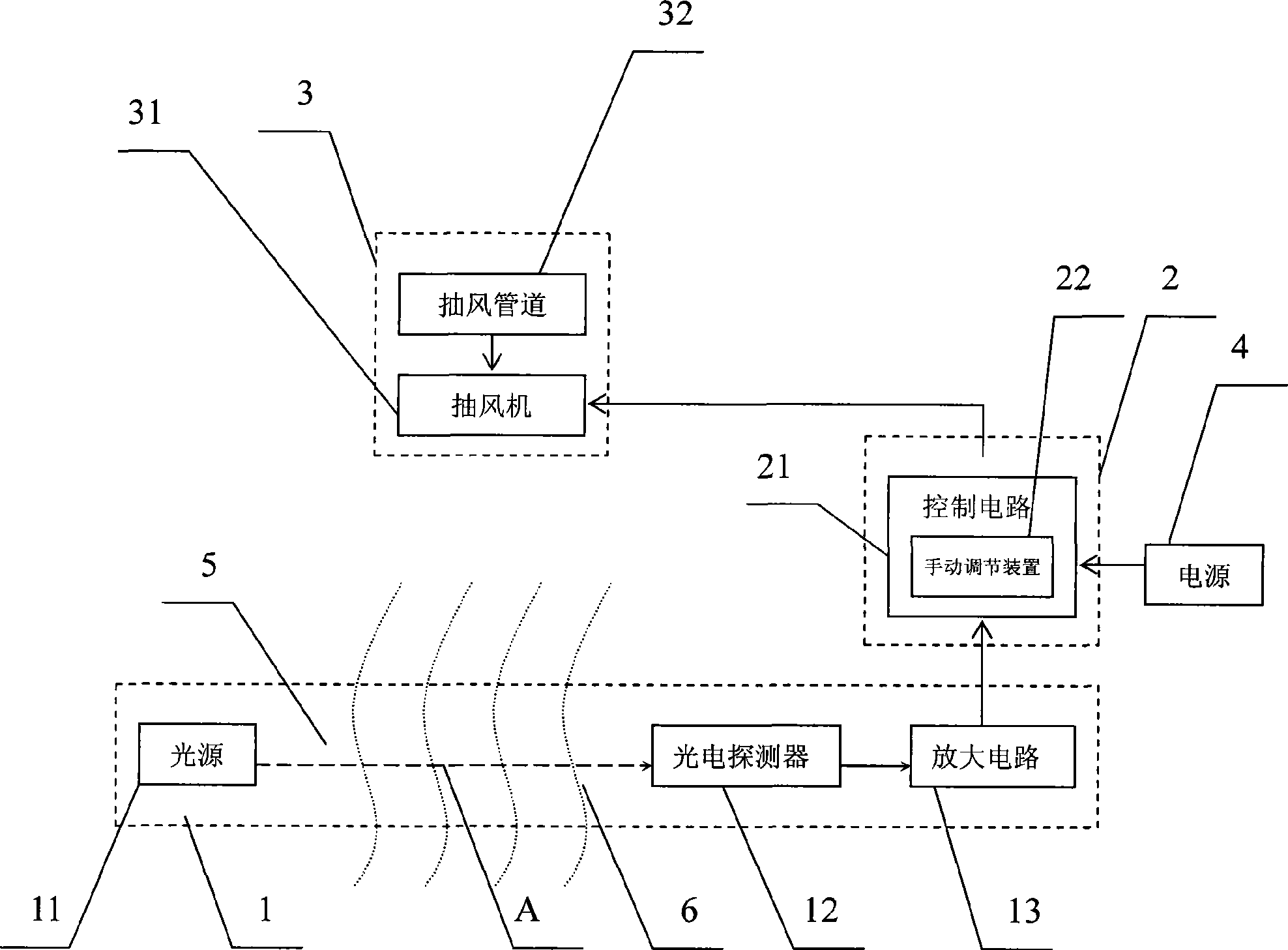

[0038] Embodiment 2 has basically the same structure as Embodiment 1, except that a manual adjustment device 22 is added to the fan speed control unit 2 , and the manual adjustment device 22 is set in the control circuit 21 and located in the operational amplifier of the control circuit 21 .

[0039] The exhaust device 3 includes a motor-driven exhaust fan 31 and an exhaust duct 32 .

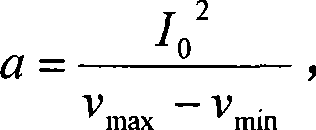

[0040] The control circuit 21 controls the draft speed of the draft device 3 by controlling the input current of the draft device 3 according to the output value v of the photoelectric detection unit 1, so the monotonically decreasing function relation I about the current is input in the operational amplifier 2 = b-av or I 2 = b-alnv.

[0041] The manual adjustment device 22 includes two adjustment devices in the control circuit 21 , one of which adjusts the constant coefficient a, and the other adjusts the constant coefficient b, so as to adjust the suction speed of the exhaust fan according t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap