Gauge head for detecting airtightness of engine air valve and valve seat

A technology for detecting engine valves and air tightness, which is applied in the field of probes, can solve the problems of bulkiness and large devices, and achieve the effects of high detection efficiency, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

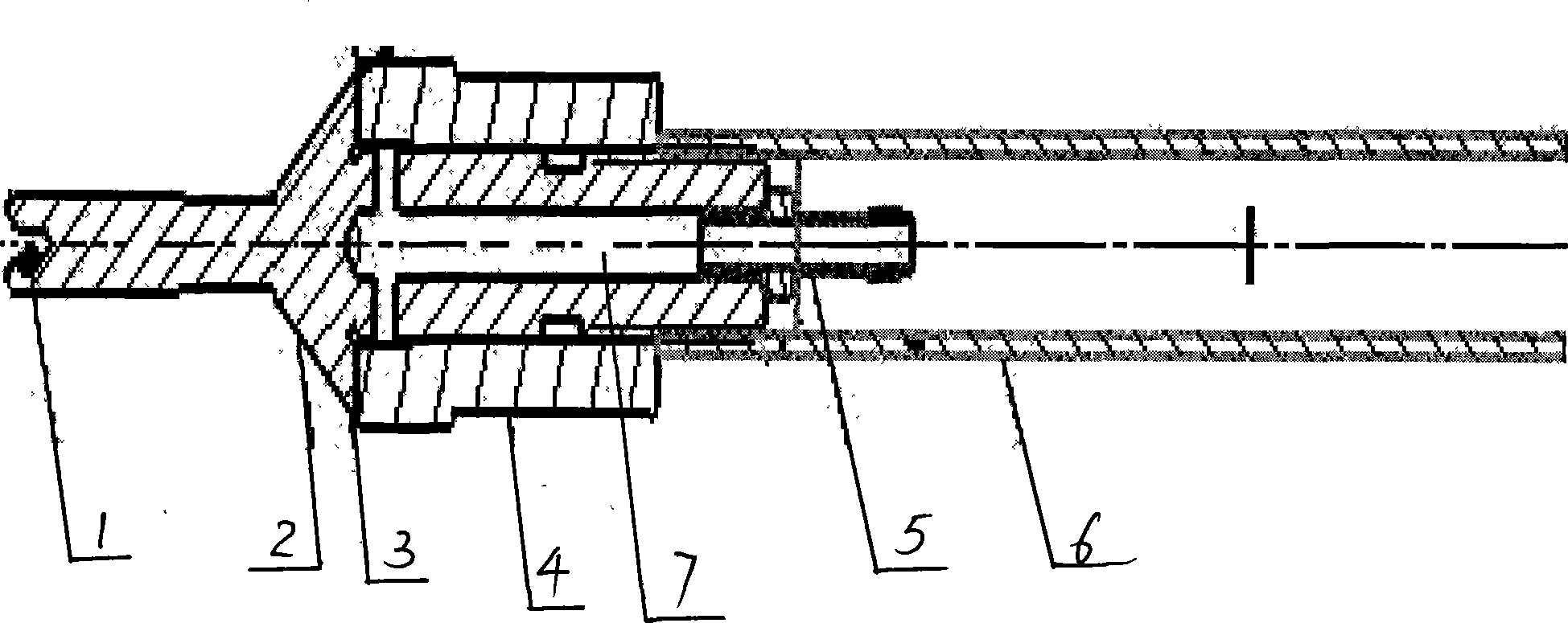

[0010] Embodiment: a kind of measuring head (referring to accompanying drawing) for engine valve and valve seat air tightness detection, it has cylindrical guide rod 1, and the lower limit of the diameter of guide rod 1 is 3-6um less than the lower limit of measured valve guide hole internal diameter, The guide rod 1 is connected to the measuring cone surface 2, the edge of the measuring cone surface 2 is provided with an annular nozzle 3, the width of the annular nozzle 3 is 0.05-0.055mm, the measuring cone surface 2 is connected to the probe body 4, and the probe body 4 is equipped with a gas The gas path 7 is connected to the air pipe 5 through the joint, the annular nozzle 3 communicates with the air pipe 5 through the air path 7, and the probe body 4 is connected to the handle 6.

[0011] When in use, connect the air pipe 5 of the measuring head to the gas outlet nozzle of the tester, insert the guide rod 1 of the measuring head into the valve guide hole of the engine cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com