Fire-resisting test apparatus with double-layer double-span frame structure and its implementing method

A technology of frame structure and test device, which is applied in the testing, measuring device, instrument and other directions of machine/structural components, can solve the problems of energy waste, inability to realize fire resistance test, inability to load building components, etc. Test data and scientific basis, fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

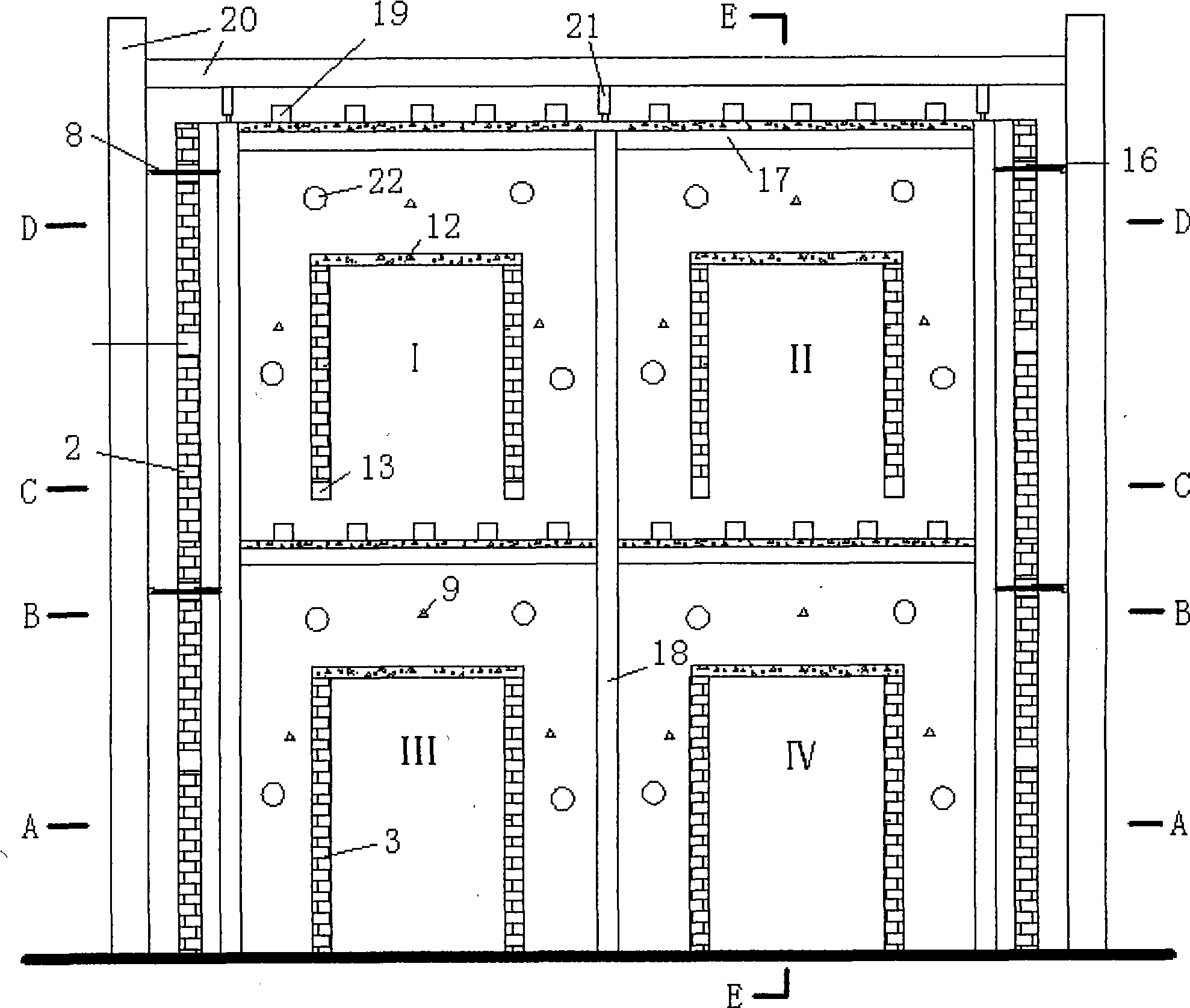

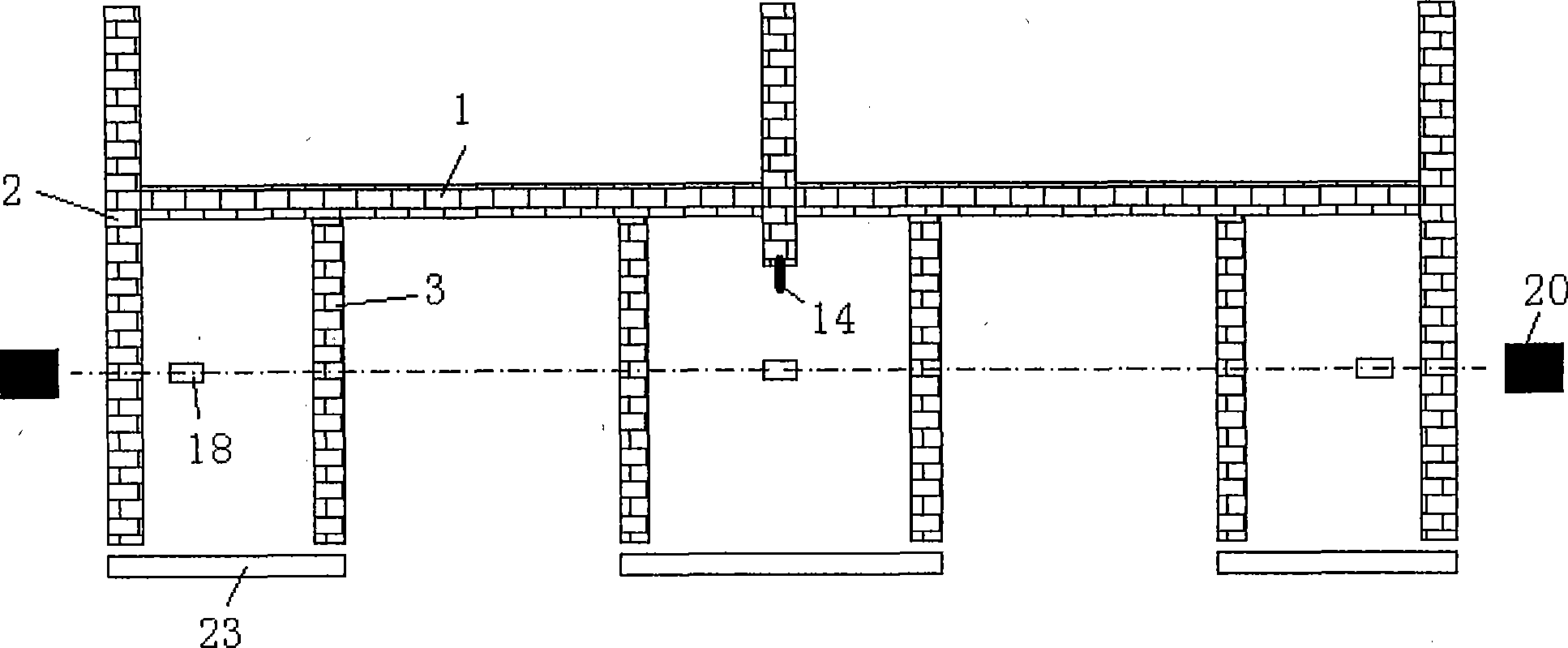

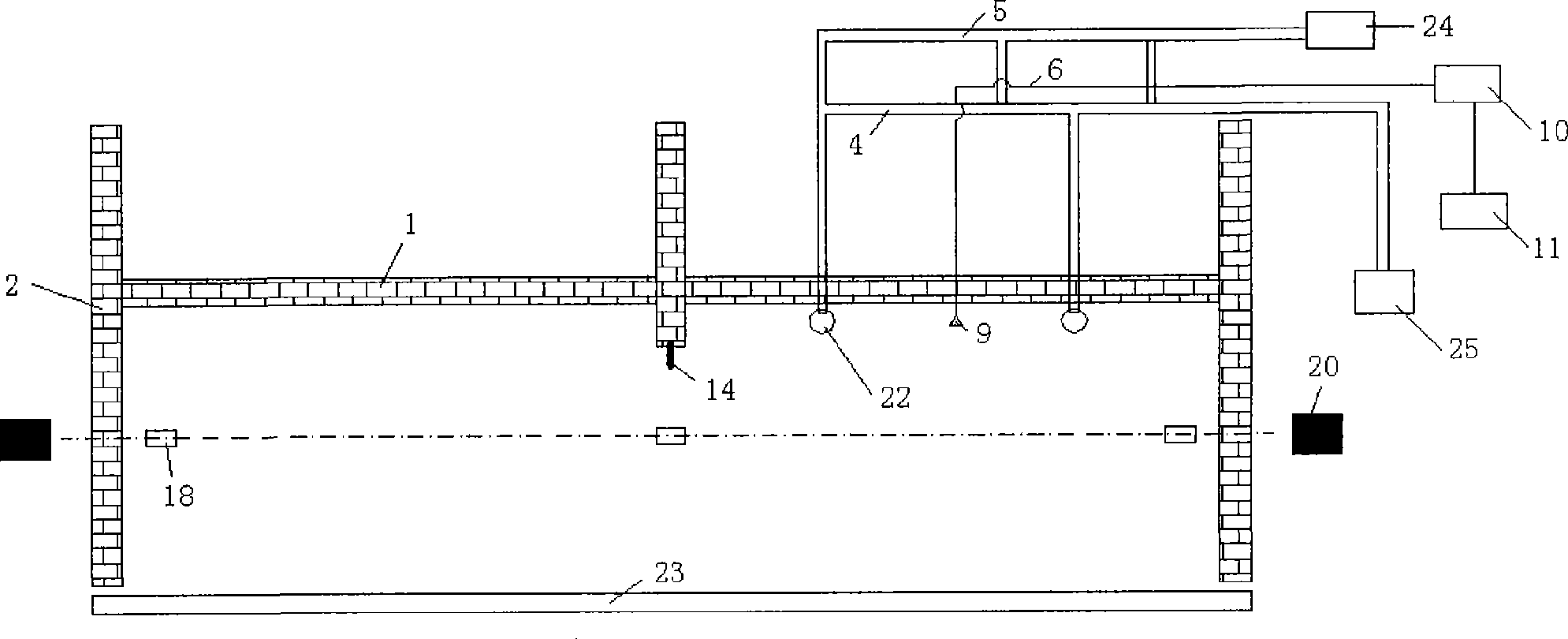

[0045] The device in this embodiment mainly includes a furnace body part, a loading device, and a measuring device. According to the characteristics of the double-layer double-span frame structure, four combustion chambers are formed through a certain arrangement. The furnace body mainly includes the outer furnace wall, the inner furnace wall of each combustion chamber, and is attached with fuel oil pipelines, weathering pipelines and related test lines. There are fire viewing holes and measuring holes on the outer furnace wall. The loading device mainly includes facilities such as a reaction frame. The measuring device mainly includes a high temperature resistant porcelain tube, a differential displacement gauge, a thermocouple, a data acquisition instrument, and a computer. The device of this embodiment can carry out the fire resistance test of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com