A method and device for generating a driving current of a solenoid valve

A technique for driving and generating a solenoid valve, applied in the direction of valve operation/release devices, valve devices, electromagnets, etc., can solve the problems of weak control reliability, inability to effectively suppress interference, and low reliability, etc., and achieve circuit production Effect of low cost, shortened opening and closing time, and reduced fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

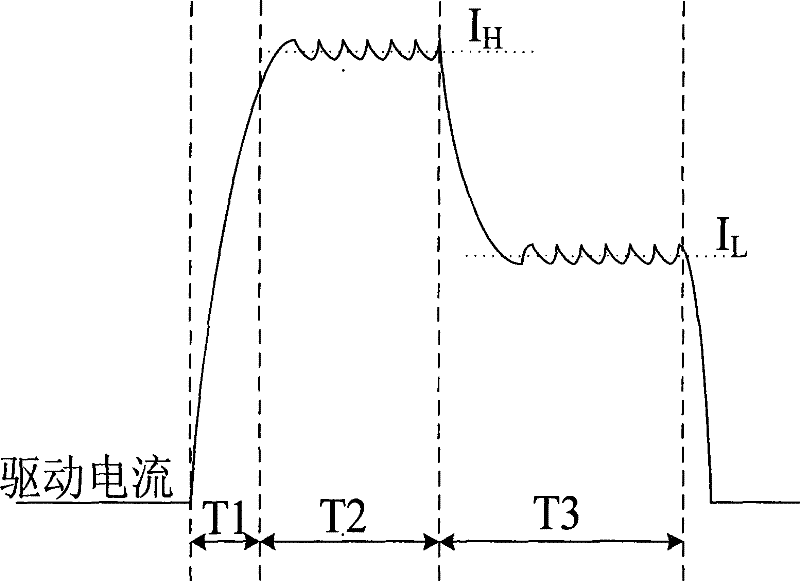

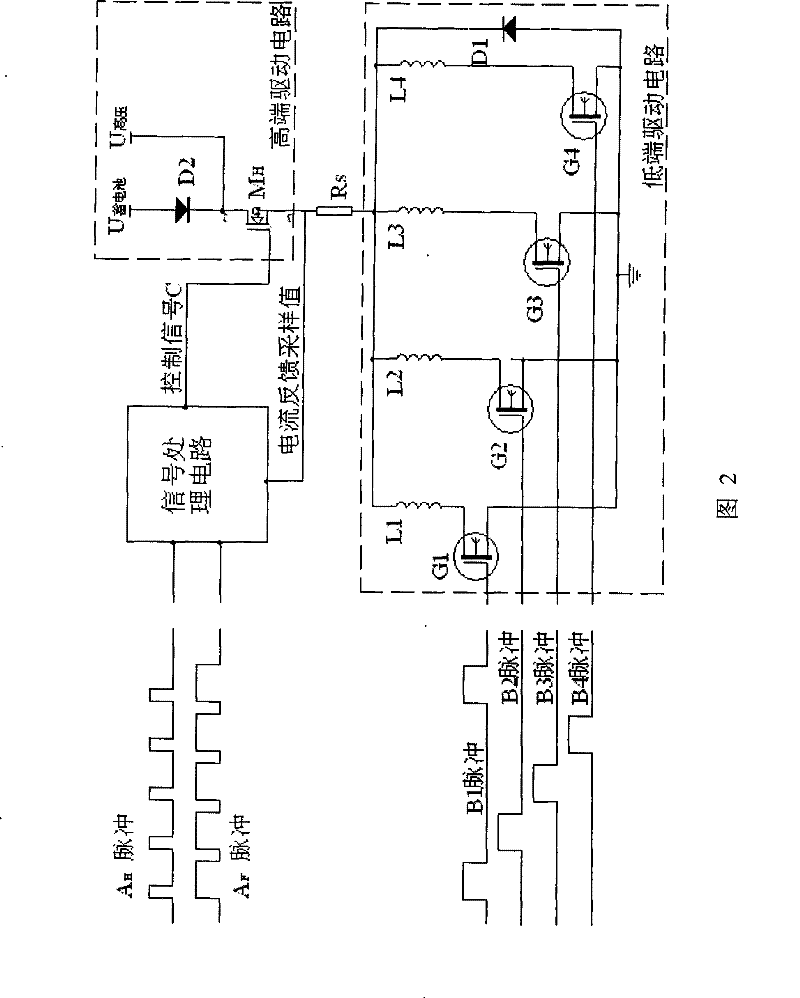

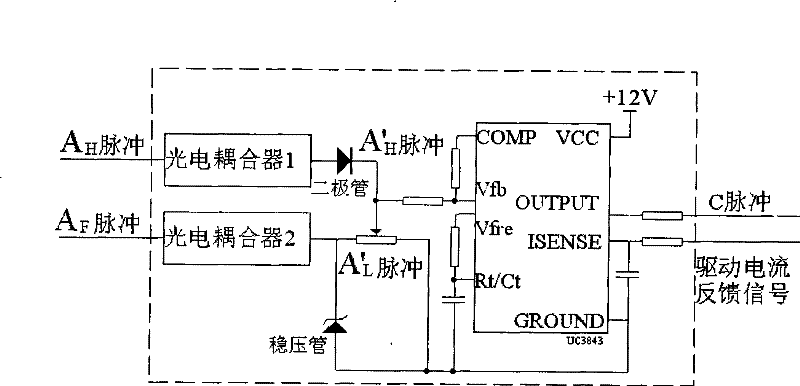

[0046] The main idea of the technical solution of the present invention is to be applicable to the generating device of the solenoid valve drive current of the engine fuel injection system, including the electronic control unit, the signal processing circuit, the high-end drive circuit, the low-end drive circuit and the sampling resistor, and the high-end drive circuit passes the sampling resistor It is connected to one end of the solenoid valve, and the low-end drive circuit is connected to the other end of the solenoid valve. The electronic control unit sends a peak current holding control pulse signal A to the signal processing circuit. H and current feedback control pulse signal A F , and send the low-end drive circuit control pulse signal B to the low-end drive circuit. When the drive current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com