Capacitance touch screen and manufacturing process thereof

A technology of capacitive touch screen and production method, which is applied in the direction of circuits, electrical components, electronic switches, etc., can solve the problems of unfixed glue overflow position, low quality or production efficiency, etc., to overcome product quality, facilitate cleaning, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] see Figure 8 , the manufacture method of capacitive touch screen provided by the present invention, specifically comprises the following steps:

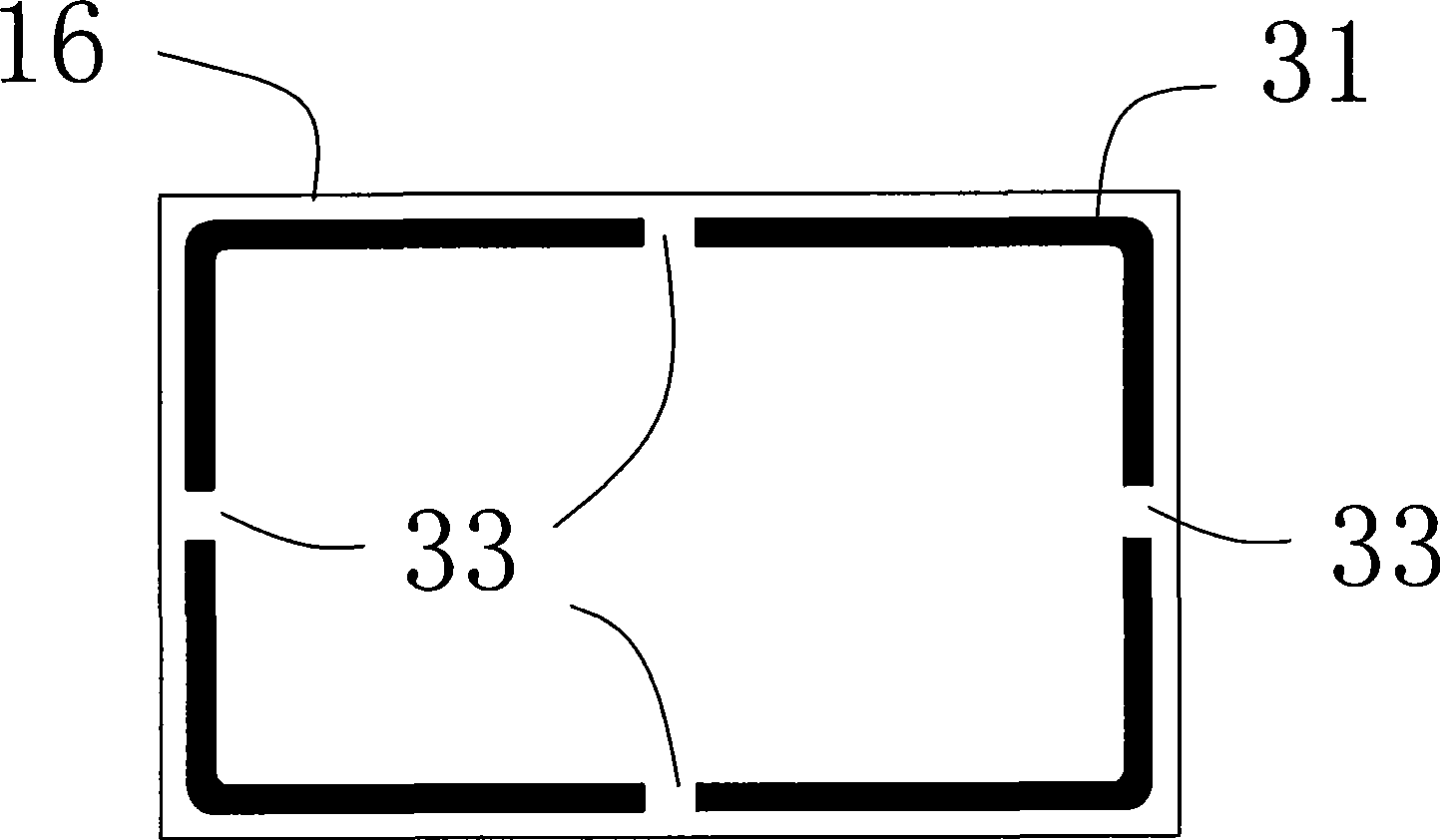

[0029] 5.1 First select any one of the prepared upper and lower substrates, such as the following substrate 16, and use a curable adhesive to make a frame glue 31 with at least one opening 33 along the periphery of the bonding surface of the substrate. The plane distribution shape of the glue on the substrate can be as follows image 3 As shown: when the frame glue 31 is rectangular, a disconnected opening 33 can be provided on each opposite sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap