Exhaust gas purifying catalyst and its manufacturing method

一种废气净化、催化剂的技术,应用在催化剂活化/制备、物理/化学过程催化剂、化学仪器和方法等方向,能够解决催化剂性能劣化、催化剂劣化、催化剂表面积减小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, an iron oxide-ceria-zirconia composite oxide having a composition of Fe:Ce:Zr (molar ratio)=5:40:55 was produced by the following microemulsion method.

[0054] Polyoxyethylene (n=5) nonylphenyl ether (NP-5) as a surfactant was added to a cyclohexane solvent to form a hydrophobic solvent. In addition, ferric nitrate, cerium nitrate, zirconyl nitrate and a very small amount of alkylammonium are dissolved in water to prepare an aqueous phase solution. The aqueous phase solution obtained above was injected into a hydrophobic solvent, and stirred continuously for 1 hour to prepare a water-in-oil microemulsion with a water droplet diameter of 40 nm. Also, in this microemulsion, the O / S ratio (the molar ratio of the hydrophobic solvent phase (oil phase) / surfactant) was 6.

[0055] Ammonia water was added to the microemulsion obtained as above to adjust the pH to 8.0, and the precursor secondary particles of the iron oxide-ceria-zirconia composite oxide were ...

Embodiment 2

[0057] Except that lanthanum nitrate was further added when preparing the aqueous phase solution, the same operation was performed as in Example 1 to obtain lanthanum oxide-iron oxide- Cerium oxide-zirconia composite oxide. The condition of this catalyst is shown in Table 1 below.

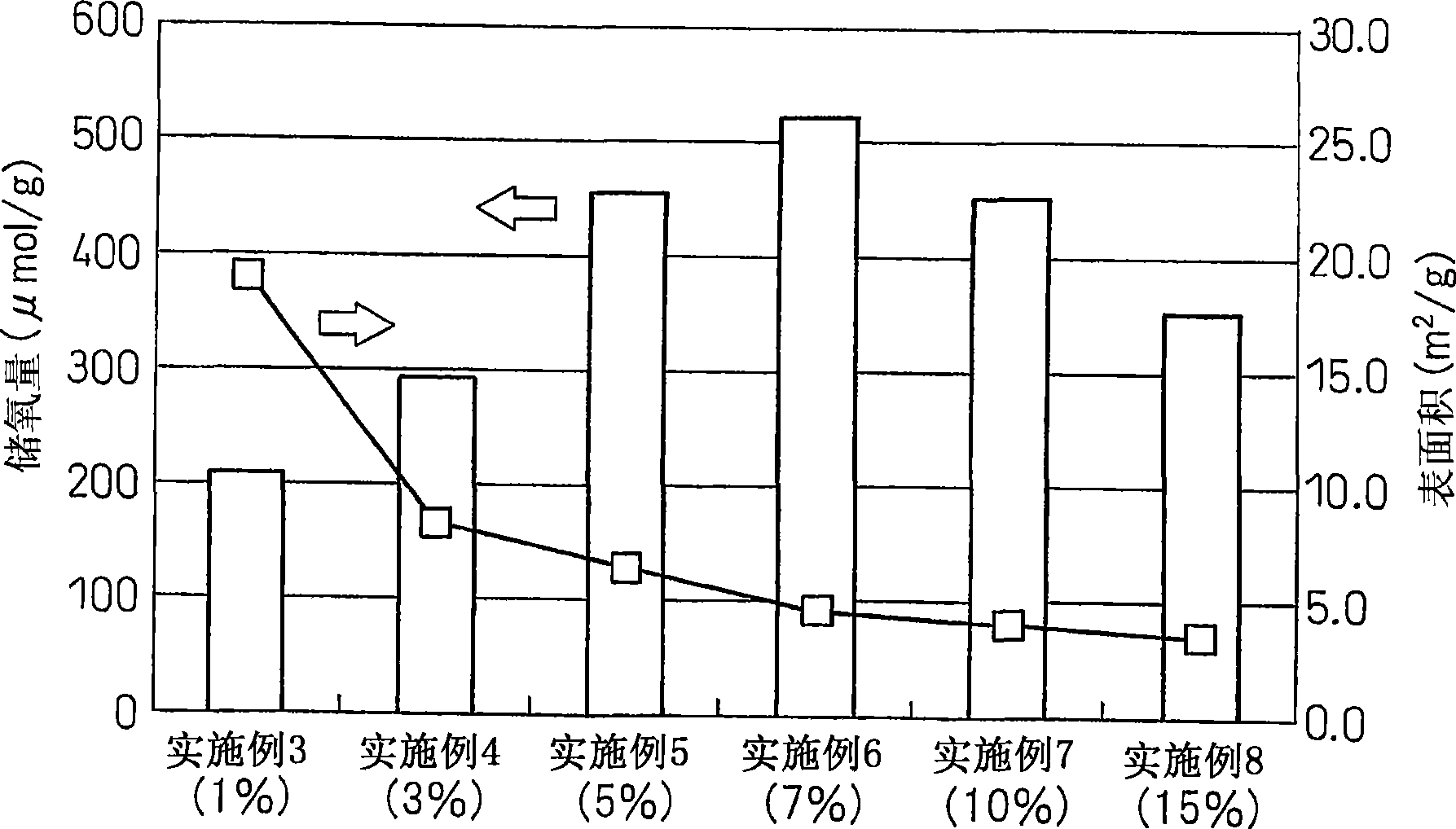

Embodiment 3~8

[0065] In the preparation of the aqueous phase solution, except that the molar ratio of La:Fe:Ce:Zr was changed as shown in Table 1 below, the exhaust gas purification catalysts of Examples 3-8 were obtained in the same manner as in Example 2.

[0066] Table 1: Catalysts of Examples and Comparative Examples

[0067]

[0068] * Relative to the carrier (AlCeZrO X )proportion

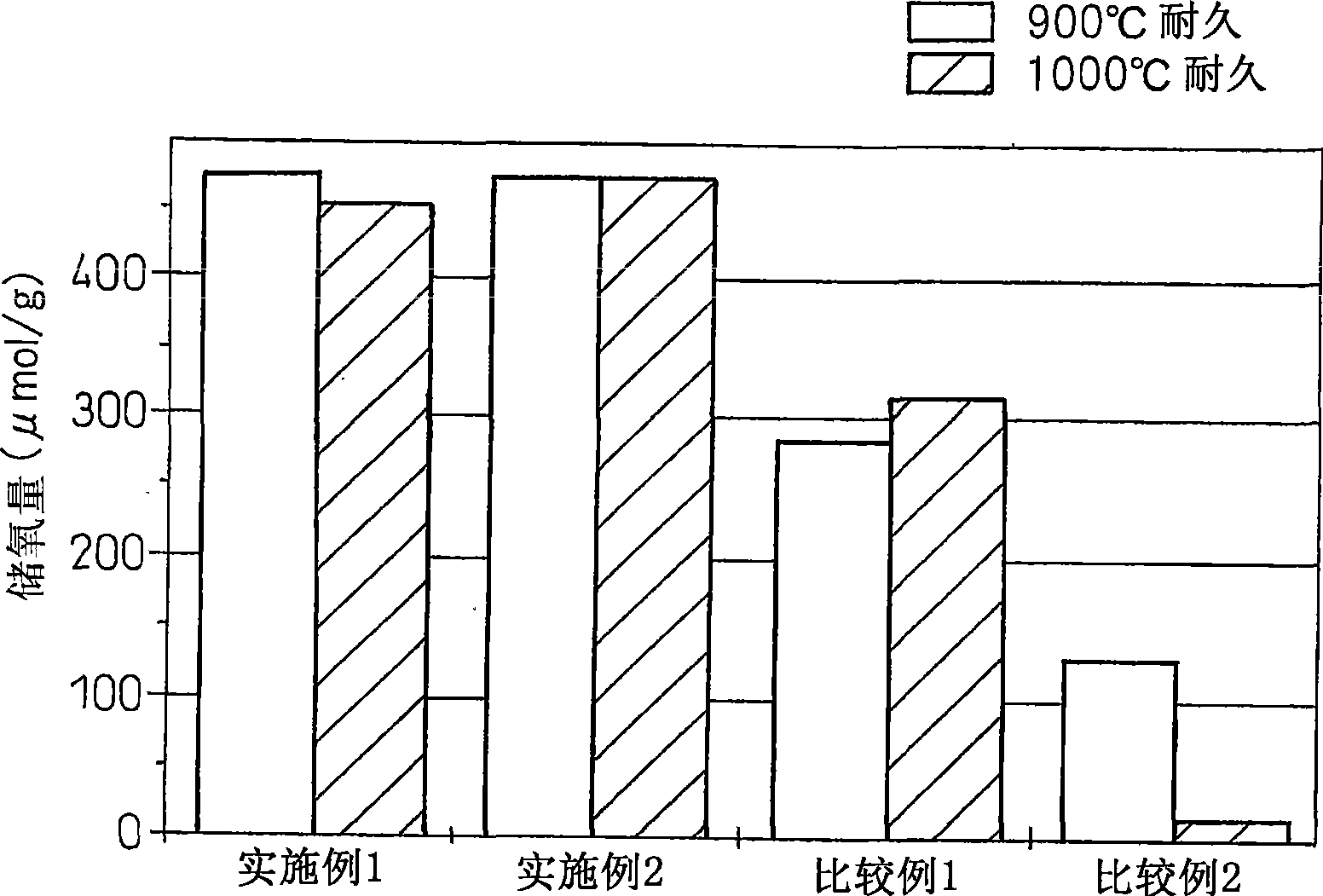

[0069] [Oxygen storage capacity (OSC capacity) evaluation 1]

[0070] The exhaust gas purification catalysts of Examples 1 and 2 and Comparative Examples 1 and 2 were durable by heating at 900° C. for 2 hours while passing a durable stoichiometric gas having the composition shown in Table 2 below. In addition, similarly, the exhaust gas purification catalysts of the above-mentioned examples and comparative examples were heated at 1000° C. for 2 hours to be durable.

[0071] Table 2 Composition of durable stoichiometric gases

[0072] N 2 (%) CO 2 (%) NO (ppm) CO (ppm) C 3 h 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com