Engine camshaft bearing cover

A bearing cap and camshaft technology, applied in the directions of engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor layout, high cost, and large volume of the first bearing cap, and achieve compact oil circuit layout and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

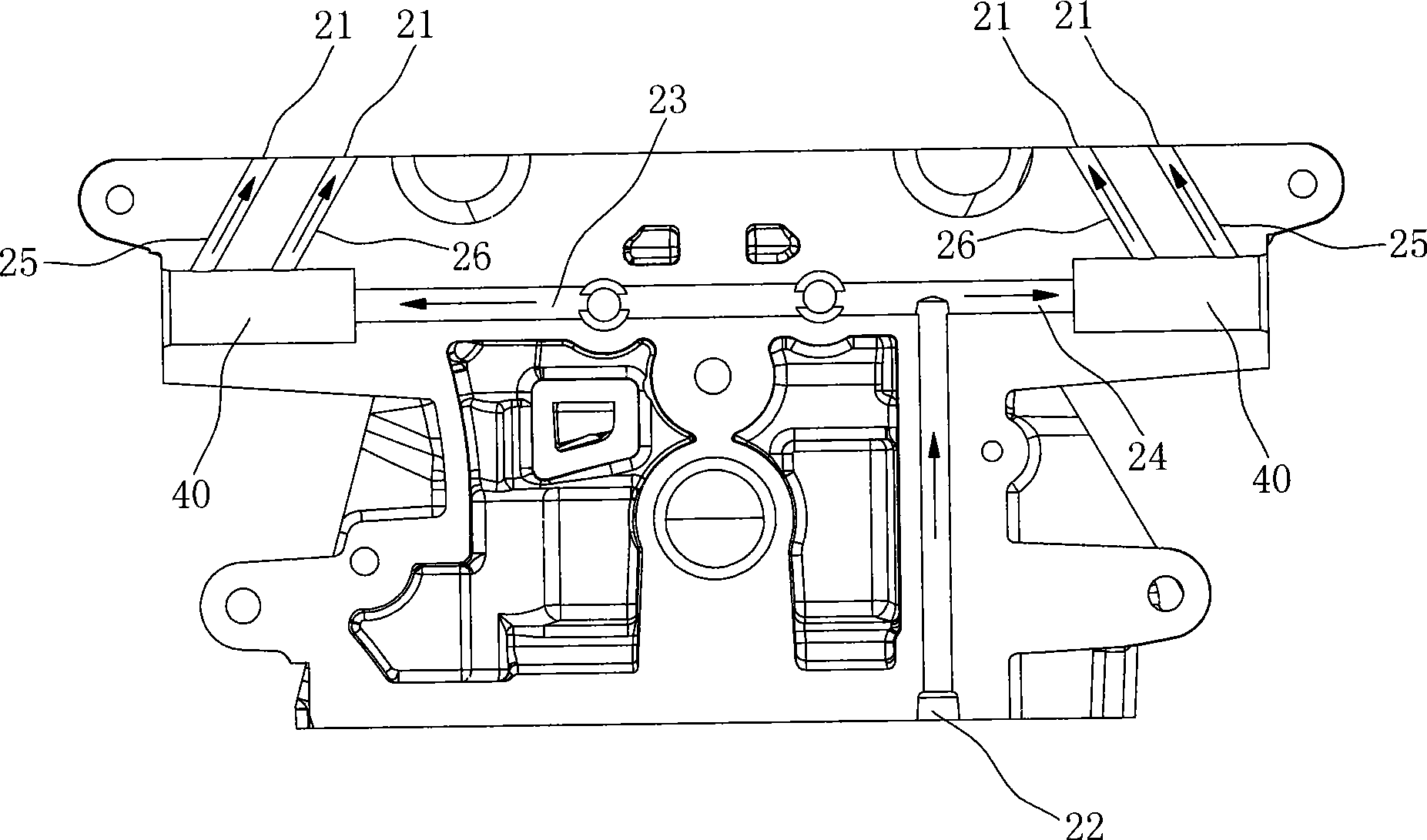

[0011] The VVT oil circuit in the prior art can be referred to figure 2 When the engine is working, the oil supplied to the oil control valve 40 is first supplied by the oil pump to the main oil hole 22 at the cylinder head 20, and then the main oil hole 22 is divided into two parts connected to the oil control valve 40 In the oil passages 23 and 24, the oil is guided by the oil control valve 40 to selectively flow into the subsequent oil passages 25 (or 26) and 27 (or 28), and then continue to supply oil to the oil chamber of the phase controller.

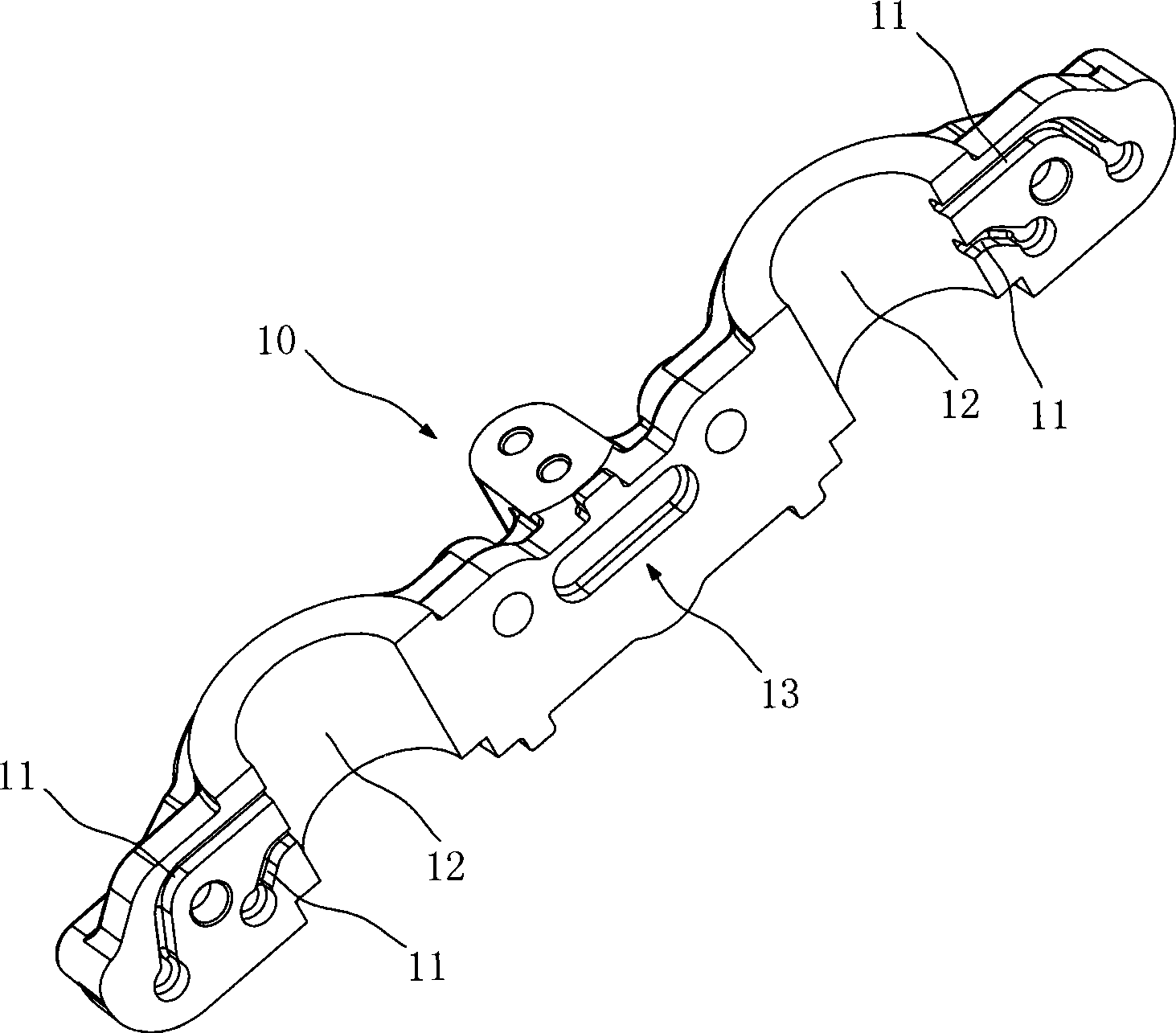

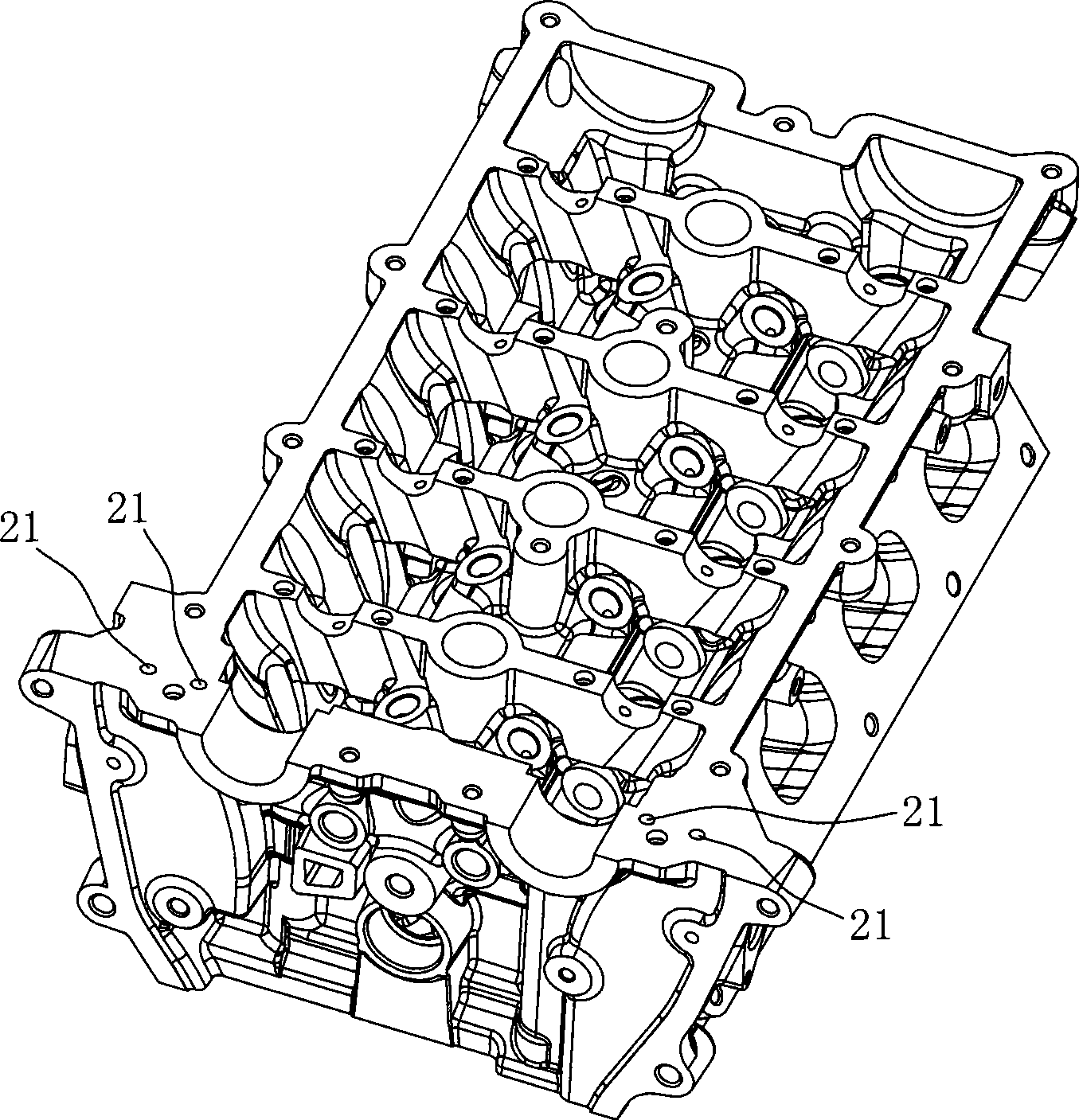

[0012] Such as figure 1 As shown, an engine camshaft bearing cap is provided with an oil groove 11 on the end surface where the bearing cap 10 is attached to the lower cylinder head 20. One end of the oil groove 11 communicates with the oil supply hole 21 on the cylinder head 20, and the other end Extending to the inner surface of the bearing hole 12 on the bearing cap 10, the oil flows through the oil control valve 40 and the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com