Piston rod connecting device

A technology of connecting device and piston rod, applied in the direction of piston, cylindrical piston, fluid pressure actuating device, etc., can solve problems such as disadvantages and achieve the effect of avoiding the twisting of the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

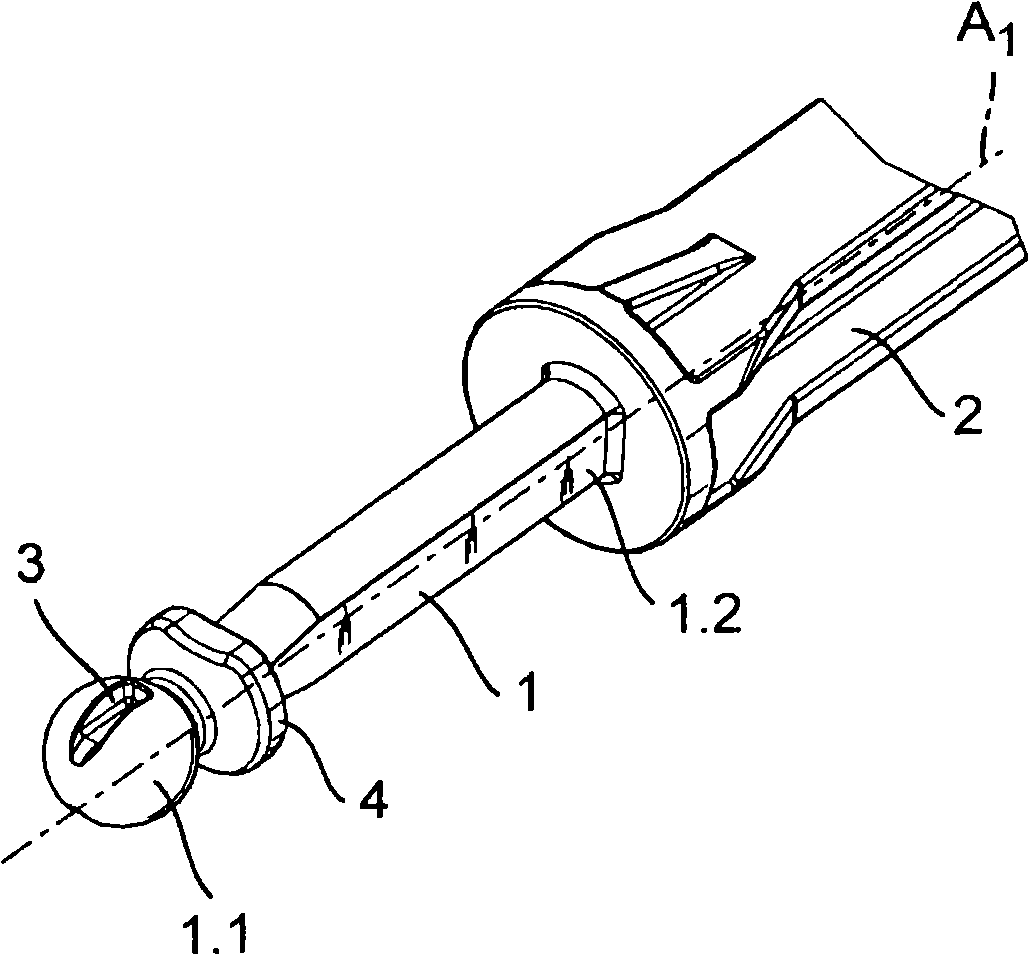

[0033] figure 1 A piston rod 1 with a spherical first end 1.1 is shown in . Connected to the second end 1.2 of the piston rod 1 is a push rod 2 which is connected to an actuating element not shown, for example a pedal. The spherical end 1 . 1 of the ball shaft 1 has two opposite groove-shaped recesses 3 , of which only one recess 3 is visible here due to the three-dimensional illustration. The recess 3 constitutes a first shaped element and is substantially aligned with the longitudinal axis A of the piston rod 1 1 Extend parallel and aligned. Attached at small intervals to the spherical first end 1 . 1 of the piston rod 1 is a flange 4 for fastening a sealing bellows (not shown).

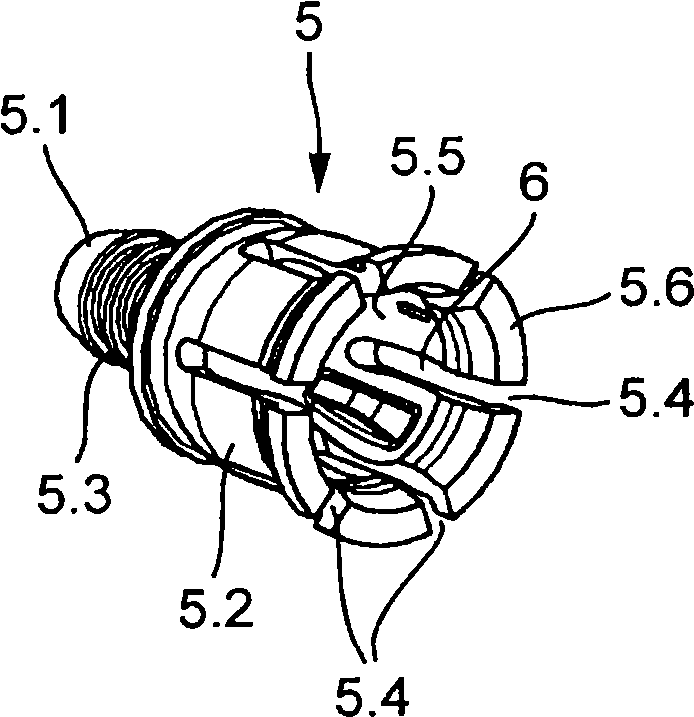

[0034] figure 2 A three-dimensional view of the adapter element 5 is shown in . The adapter element has a plug-in area 5.1 and a receiving area 5.2 for snap-in figure 1 The spherical first end 1.1 of the piston rod 1 is shown in . The plug-in area 5.1 is designed to be rotationally symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com