Biomass energy gasification furnace apparatus

A biomass energy and gasifier technology, applied in coke ovens, household appliances, household stoves/stoves, etc., can solve the problems of intractable coke dust, occupying market share, and slow progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

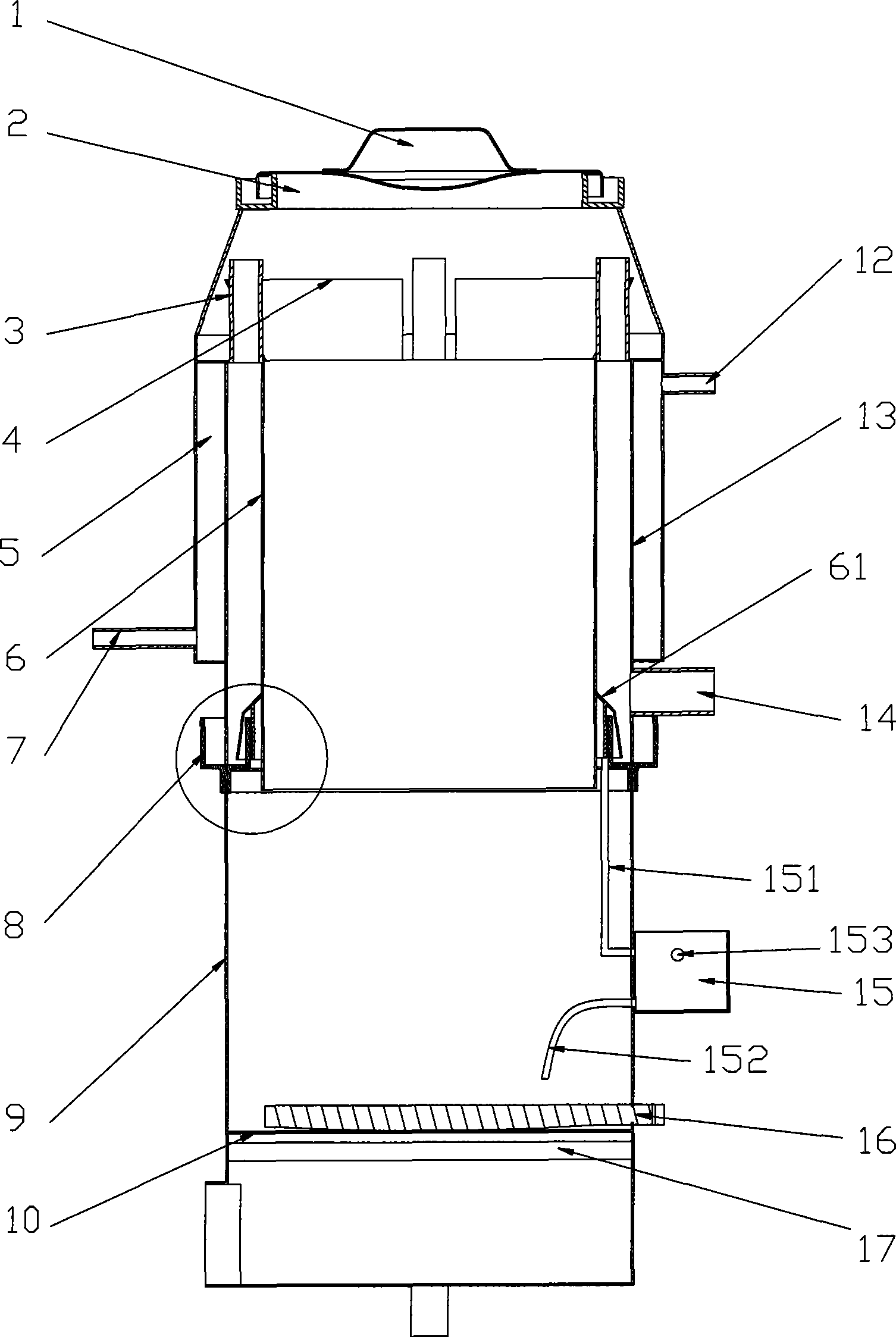

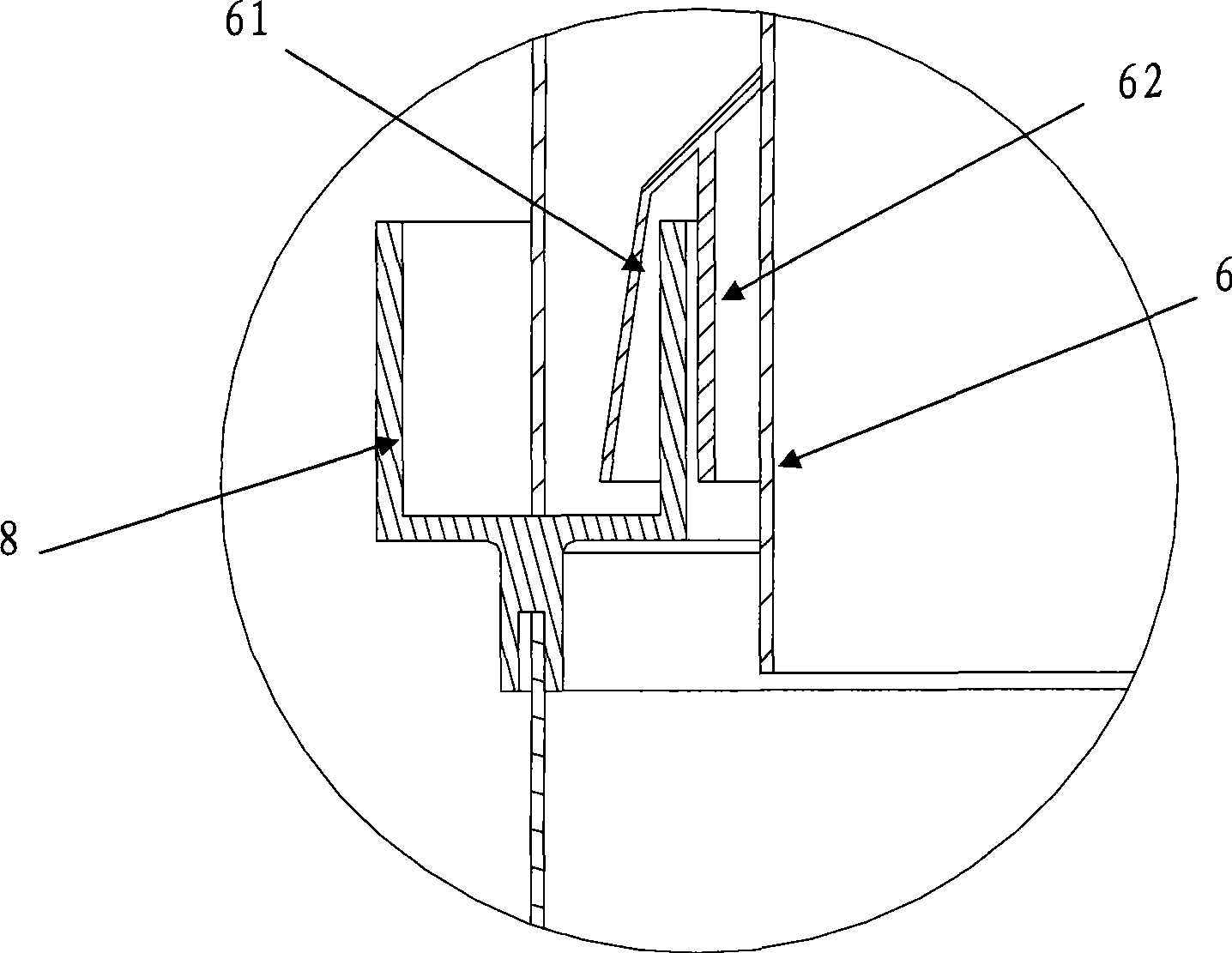

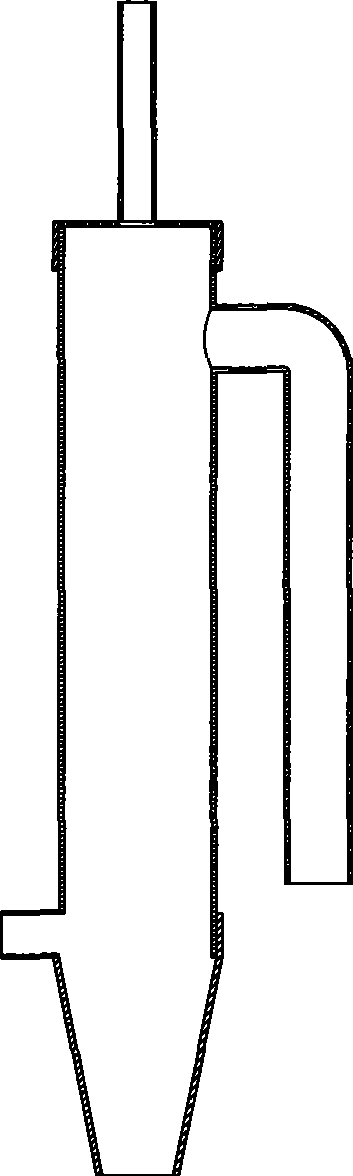

[0021] Such as Figure 1 to Figure 5 As shown, the biomass gasification furnace appliance of the present invention includes upper and lower furnace bodies 9, 13 coaxially arranged, and a U-shaped water sealing groove 8 is upwardly arranged on the upper end of the lower furnace body 9, and the The lower end of the upper furnace body 13 is arranged in the U-shaped water seal groove 8, so that the upper and lower furnace bodies are easily disassembled, convenient for the maintenance of the furnace body, and the sealing effect is also good, and the use of two furnace bodies increases the fuel storage capacity , to prolong the gasification time; the middle and lower part of the lower furnace body 9 is provided with a fire grate 16; the top of the upper furnace body is provided with a feed port 2, and a furnace cover 1 is provided at the feed port, Furnace c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com