Power transmission control device, power transmitting device, non-contact power transmitting system, and electronic instrument

A technology of power transmission device and control device, applied in circuit devices, electromagnetic wave systems, battery circuit devices, etc., can solve problems such as equipment damage, and achieve the effect of suppressing power consumption and high convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

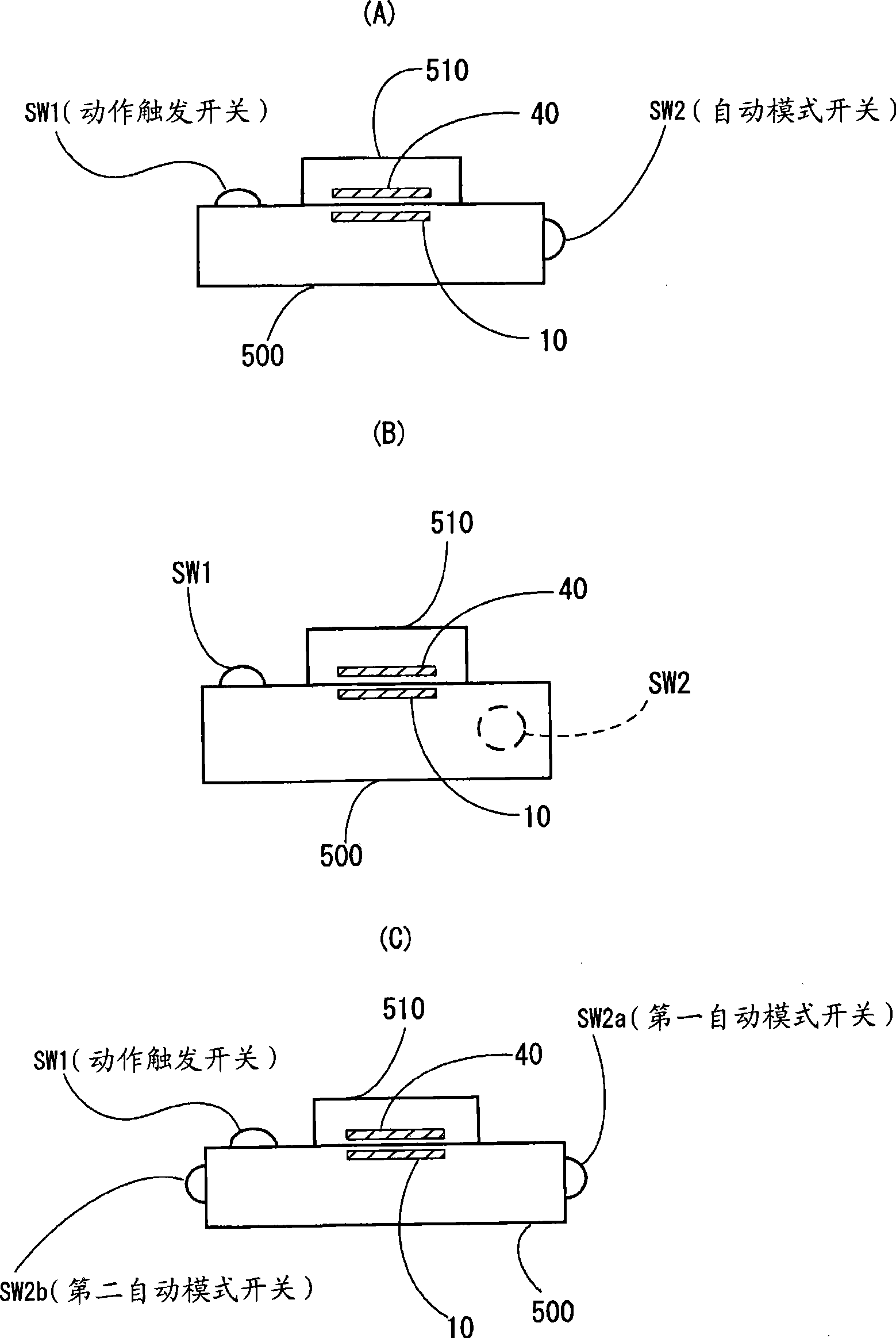

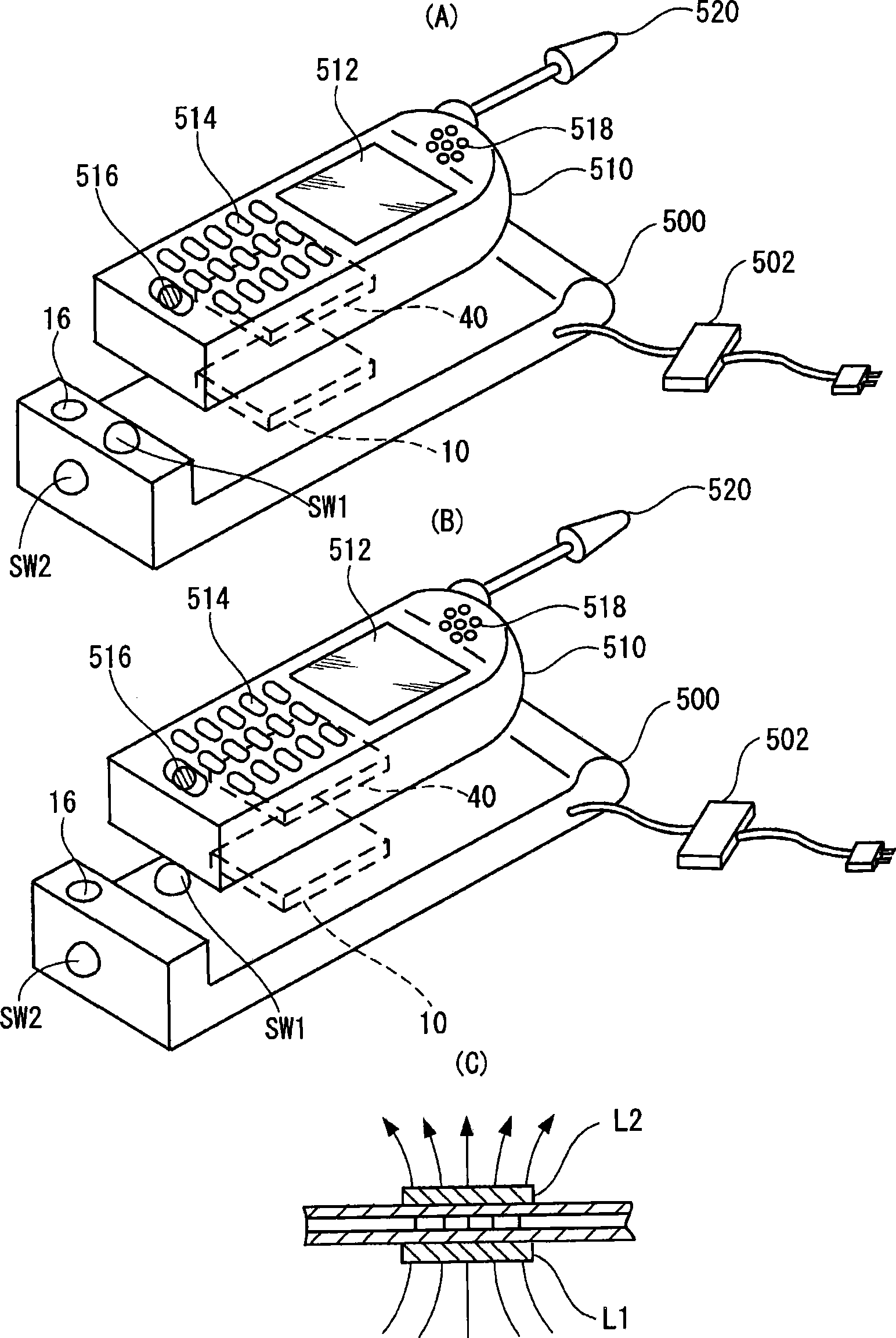

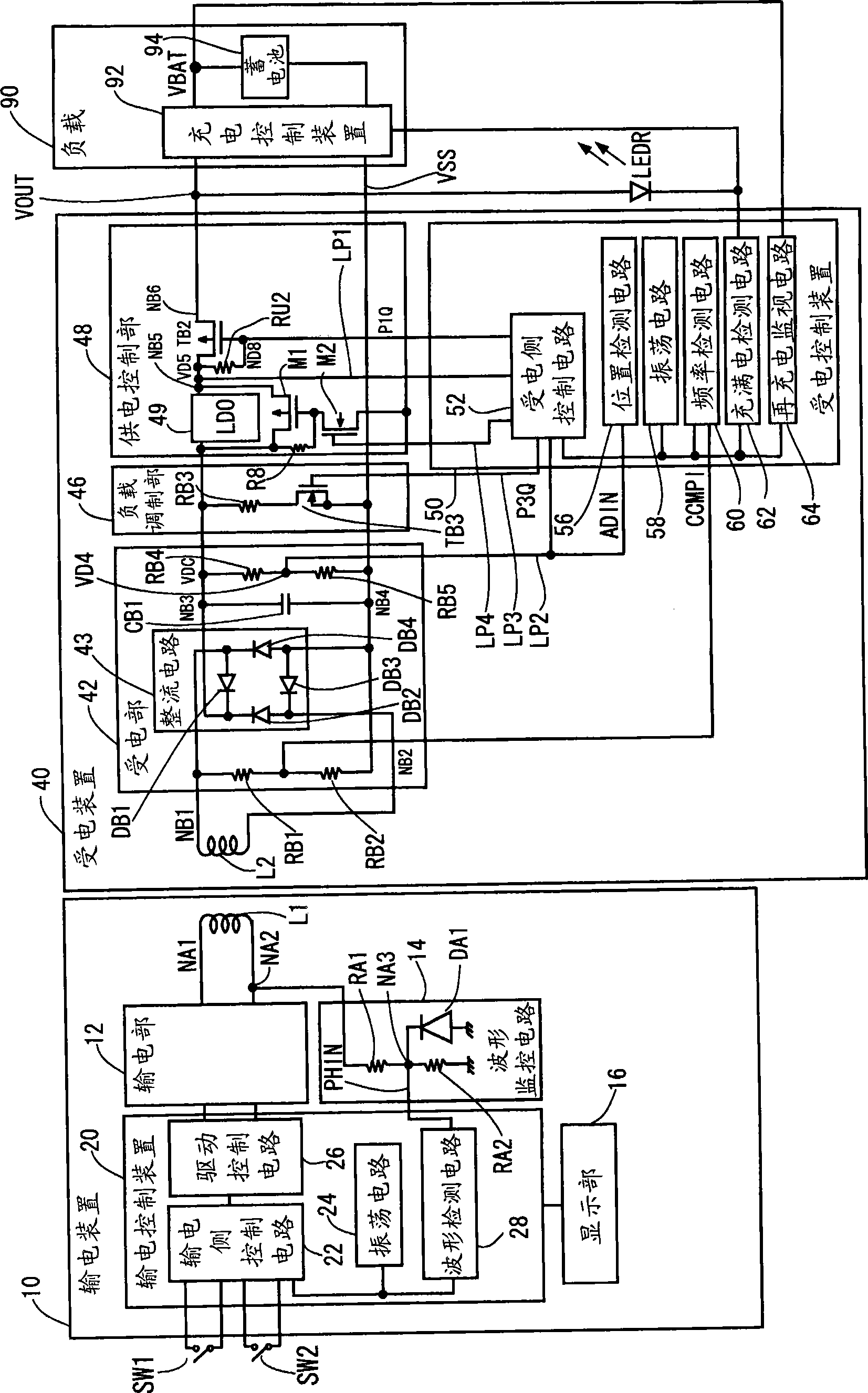

[0081] figure 1 (A)~figure 1 (C) shows an outline of a configuration example of a non-contact power transmission system capable of switching between the switch mode and the automatic mode. figure 1 The contactless power transmission system of (A) includes: a power transmission side device (for example, a charger (pallet)) 500; a power reception side device (for example, a portable phone terminal) 510, which is loaded on the power transmission side The contact power transmission charges the secondary battery (battery). The power transmission device 10 is built in the power transmission side equipment 500 . In addition, the power receiving device 40 is built in the power receiving side equipment 510 . The power receiving device 40 can be attached to the power receiving side device 510 from the outside using an adapter or the like.

[0082] figure 1 (A) The non-contact power transmission system can switch between switch mode and automatic mode. An operation trigger switch SW...

no. 2 approach

[0152] In this embodiment, the operation of the non-contact power transmission system when the automatic mode is selected will be described.

[0153] (Outline of operation of power transmission device in automatic mode)

[0154] Figure 8 It is a schematic flowchart showing an example of the operation of the power transmission device in the automatic mode. As described above, the power transmission side control circuit 22 of the power transmission device 10 of the present invention can automatically detect the setting of the power reception side device 510, and can also perform recharging management after full charging. Therefore, the operation mode in which the power transmission device 10 automatically executes a series of operations is called an automatic mode.

[0155] exist Figure 8 , as shown in the part surrounded by a thick dotted line, the operations of the power transmission device 10 in the automatic mode are roughly divided into "installation detection and conf...

no. 3 approach

[0298] In this embodiment, the operation procedure of the non-contact power transmission system in the switching mode will be described.

[0299] (Outline of operation of power transmission device in switch mode)

[0300] Figure 24 It is a schematic flowchart showing an example of the operation of the power transmission device in the switching mode. As shown by the part surrounded by a thick dotted line, the operation of the power transmission device 10 is roughly divided into "confirmation of the power transmission target (step SA)" before power transmission, and "confirmation of the power transmission environment during power transmission (including before power transmission) (step SB)". .

[0301] As described above, the power transmission device 10 starts temporary power transmission when the switch ( SW1 ) is turned on (steps S1 , S2 ).

[0302] Next, it is checked whether the installation location of the power receiving side device 510 is appropriate (step S3), ID au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com