Speed regulating electricity generator with constant frequency

A technology of speed regulation and main shaft, which is applied in the direction of controlling generators, electric components, electrical components, etc., can solve the problems of high cost, complex inverter structure, high failure rate, etc., and achieve low energy consumption, simple structure, and low maintenance costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

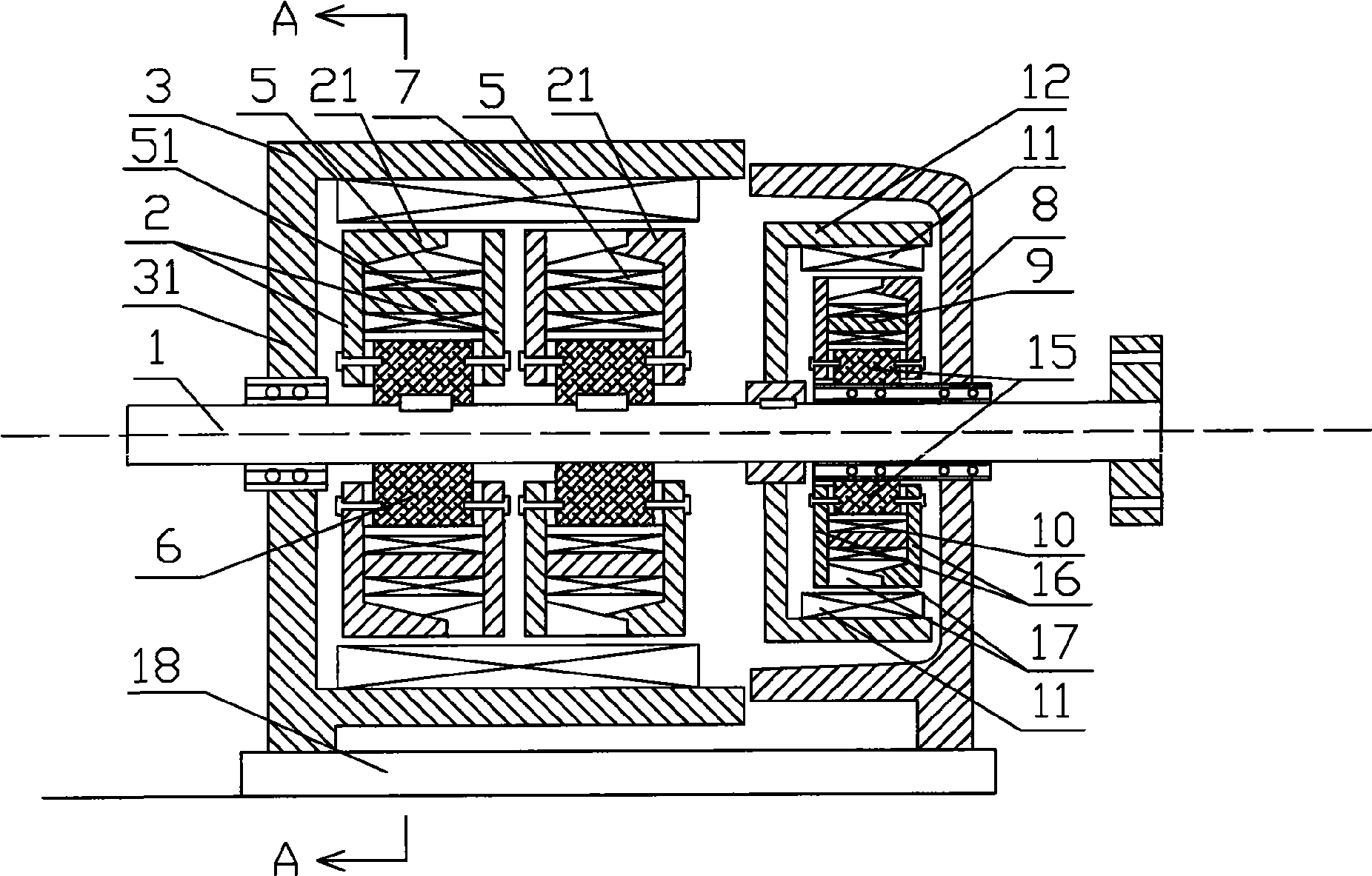

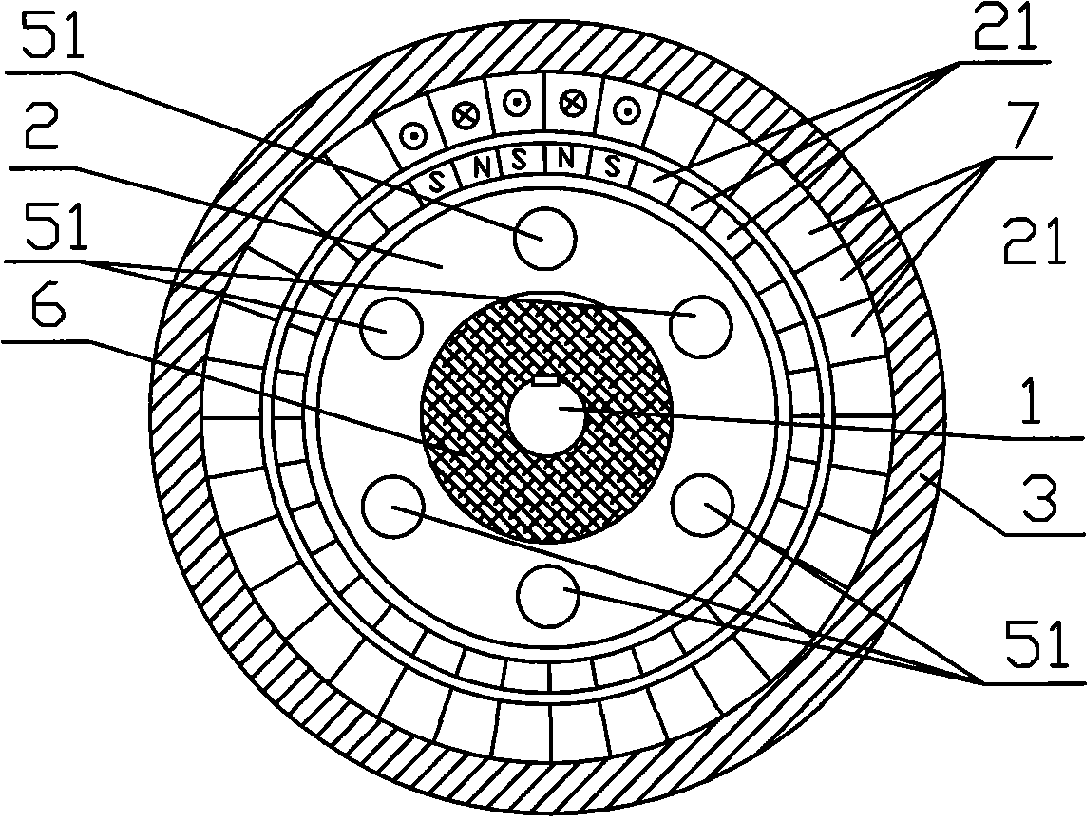

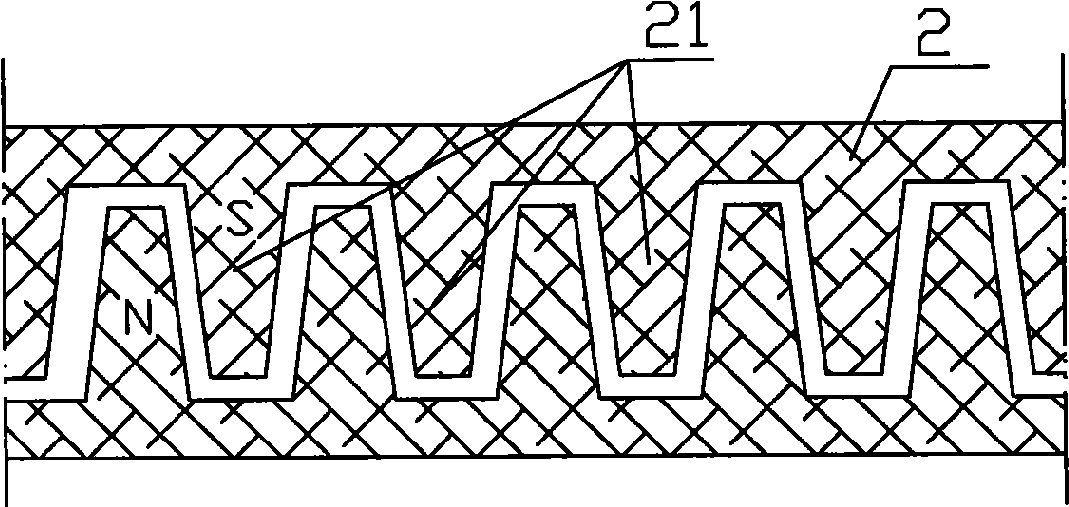

[0020] Such as figure 1 As shown, the speed-adjusting constant-frequency generator of the present invention includes a main shaft 1, a rotor fixedly installed on the main shaft 1, and a stator 3 surrounding the rotor, and the stator 3 is installed on the main shaft 1 through bearings. The rotor includes a claw pole plate 2, an iron core 51, and a rotor coil 5. The iron core 51 is fixedly installed between two opposing claw pole plates 2. The claw pole plate 2 is disc-shaped and made of a material with good magnetic permeability. Even pairs of tooth-shaped claw poles 21 are evenly distributed along the periphery of the peripheral portion thereof. The shape of the claw poles 21 is approximately trapezoidal. Such as figure 2 , image 3 As shown, two claw pole plates 2 are arranged relatively parallel in the form of staggered claw poles 21 . The claw pole plate 2 is fixedly installed on the main shaft 1 through the installation hole in its center, and a plurality of iron cores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com