Process for producing starch-containing food, and enzyme preparation for modification of starch-containing food

A manufacturing method, enzyme preparation technology, applied in food preparation, baked food, biochemical equipment and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

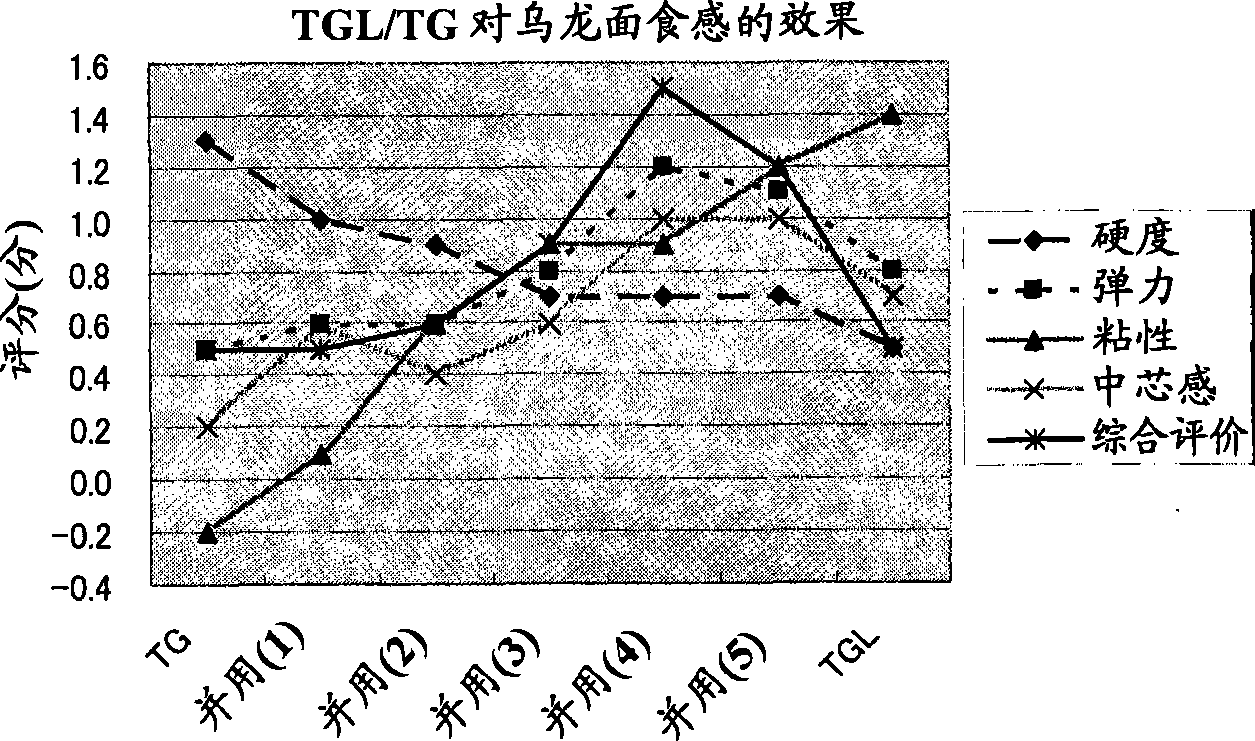

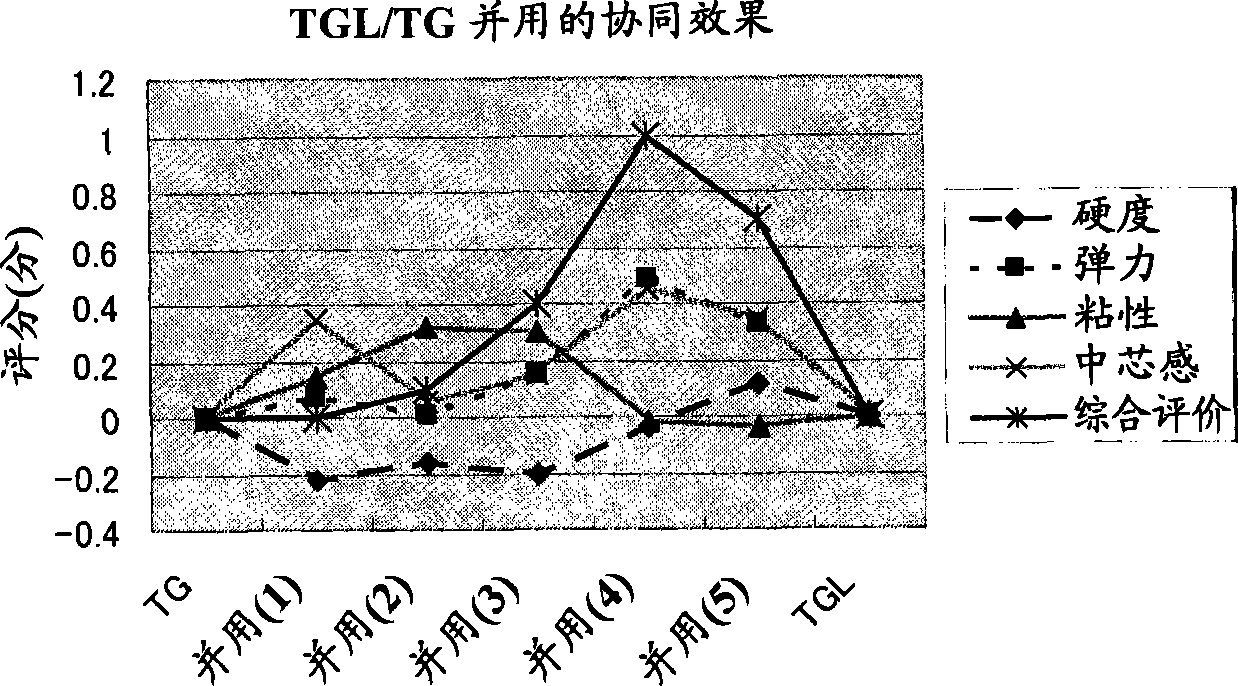

[0044] Embodiment 1: udon noodles

[0045] TGL was added to 750g of Chinese flour "Finch" (manufactured by Nisshin Milling Co., Ltd.), 250g of modified starch "Ajisai" (manufactured by Matsutani Chemical Industry Co., Ltd.), and 20g of wheat gluten "Aglu-G" (manufactured by Glico Nutritional Foods Co., Ltd.) and TG were mixed for 1 minute at a rotation speed of 100 rpm using a kneader "2 kg vacuum kneader" (manufactured by Otake Noodle Machine Co., Ltd.). The test groups were divided into the following 8 test groups: the control group without enzyme addition, the group with only TGL added, the group with only TG added, and the group with TGL and TG added at the same time in 5 ratios. The amount of enzyme added in each test group is shown in Table 1. The entire amount of 5° C. salt water in which 30 g of salt was added to 410 g of tap water was added to the above mixed raw material, and kneaded by a kneader for 5 minutes (100 rpm: 2 minutes, 50 rpm: 3 minutes). After kneading...

Embodiment 2

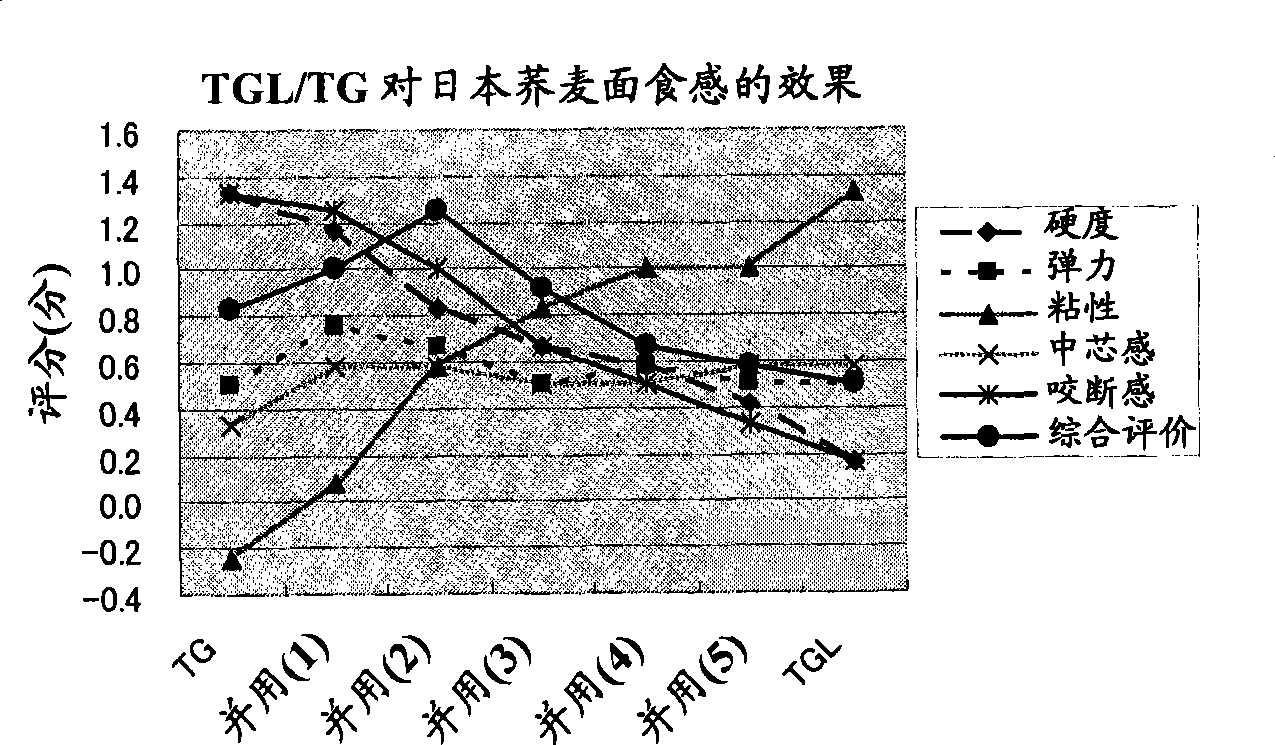

[0049] Example 2: Soba Noodles

[0050] Add TGL and TG to 500g of buckwheat flour "Heiwa" (manufactured by Hokto Milling Co., Ltd.) and 500g of strong flour "Aoji" (manufactured by Nissin Milling Co., Ltd.), and use a kneader "2kg vacuum kneader" (Otake noodles machine company) at 100 rpm for 1 minute. The test groups were divided into the following 8 test groups: the control group without enzyme addition, the group with only TGL added, the group with only TG added, and the group with TGL and TG added at the same time in 5 ratios. The amount of enzyme added in each test group is shown in Table 2. The entire amount of 5° C. salt water in which 15 g of salt was added to 350 g of tap water was added to the above mixed raw material, and kneaded by a kneader for 5 minutes (100 rpm: 2 minutes, 50 rpm: 3 minutes). After kneading, the dough was kneaded and kneaded with a noodle making machine "small rough noodle machine and small continuous calender" (manufactured by Tom Co., Ltd.),...

Embodiment 3

[0054] Example 3: Pasta

[0055]TGL and TG were added to 2 kg of durum wheat flour "DF" (manufactured by Nisshin Flour Co., Ltd.), and mixed well. The test groups were divided into the following 8 test groups: the control group without enzyme addition, the group with only TGL added, the group with only TG added, and the group with TGL and TG added at the same time in 5 ratios. The amount of enzyme added in each test group is shown in Table 2. 540 g of tap water was added to the above-mentioned mixed raw materials, and kneaded for 15 minutes with a kneader "vacuum mixer VU-2" (manufactured by Okuba Iron Works Co., Ltd.) (the speed of the kneader is set to 100). After kneading, the pasta machine "vacuum extruder FPV-2" (manufactured by Nippn Engineering Co., Ltd.) was used to extrude pasta using an extrusion die having a length of 1.8 mm. The extruded noodles were dried with a dryer "Constant Temperature and Humidity Tank LH21-13P" (manufactured by Nagano Scientific Machinery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com