bundler

The technology of a binding device and a binding belt, which is applied in the field of binding devices for binding goods, can solve the problems of insufficient binding, increasing the difficulty of control, and small tension force of the binding belt, etc., and achieves reasonable line layout, easy implementation, and overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

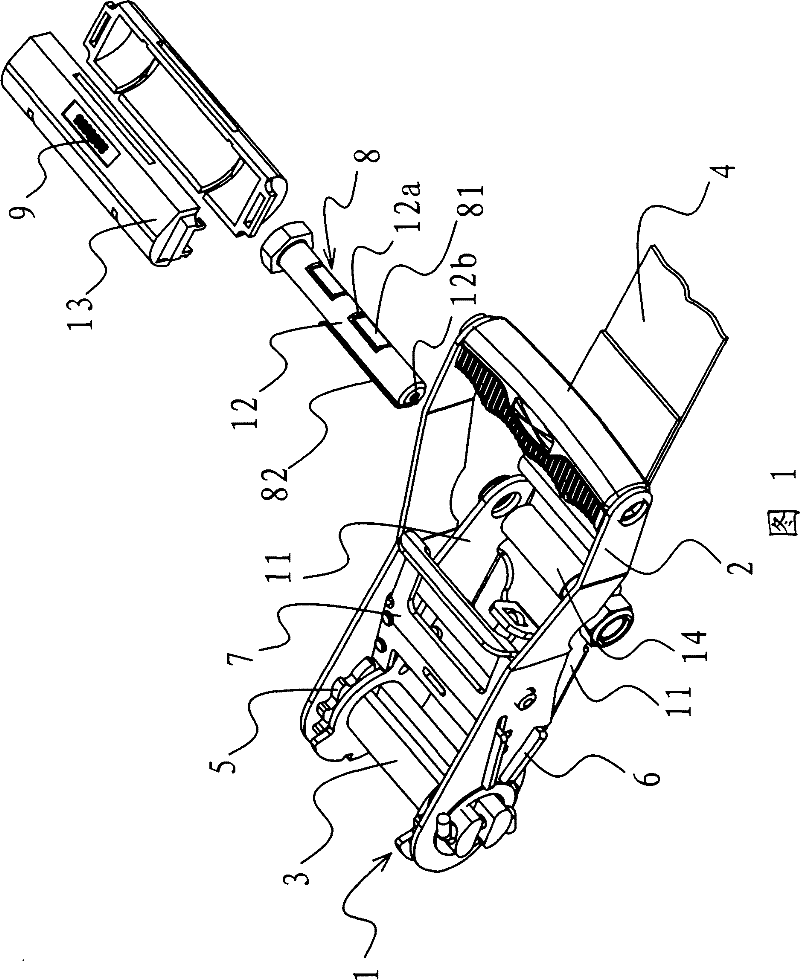

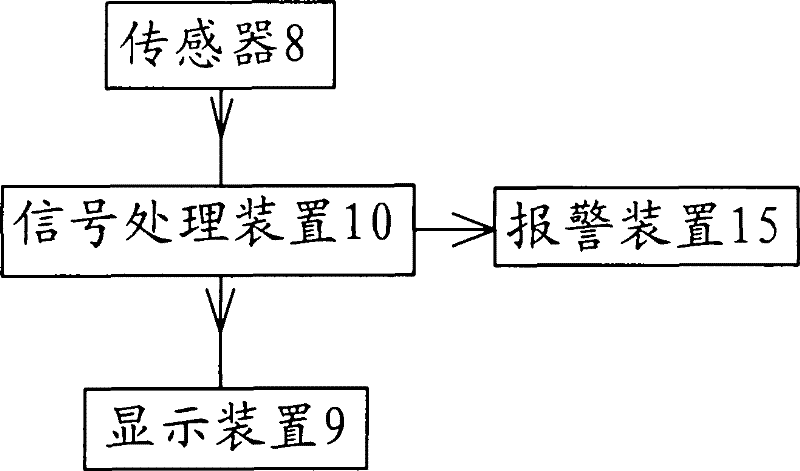

[0031] like figure 1 As shown, the binding device bracket 1, handle 2, reel 3, binding belt 4, movable belt hook, positioning belt hook, ratchet 5, tooth blocking plate 6, handle 7, sensor 8, display device 9 and other components.

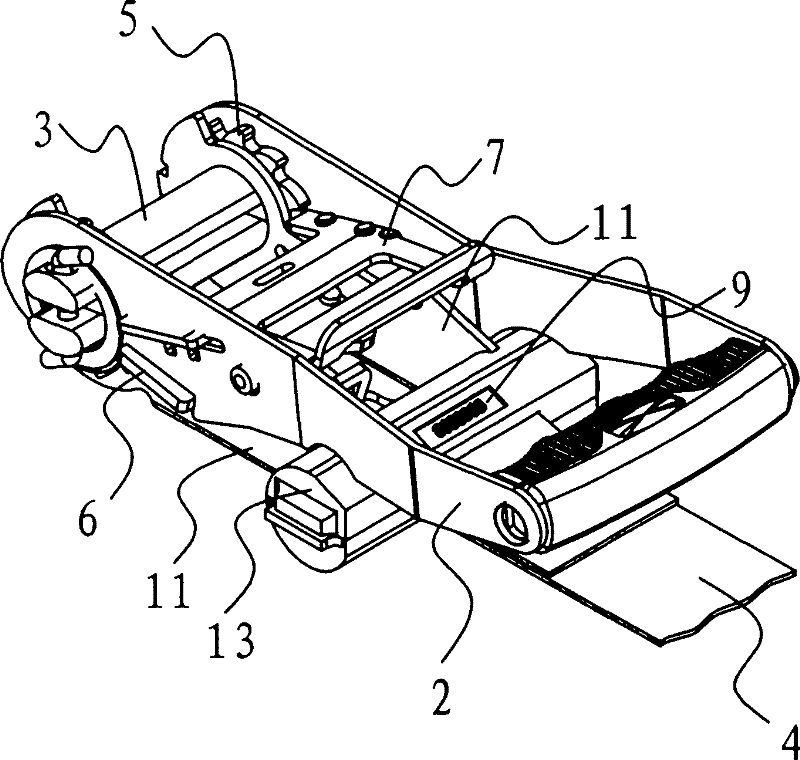

[0032] like figure 1 , 3 , 4 and 5, the bracket 1 includes two parallel side pieces 11 and a horizontal shaft 12, the handle 2 is hinged on the bracket 1 through a reel 3, and a ratchet 5 is fixed on the reel 3. The reel 3 passes through one end of the side body 11 , and the horizontal shaft 12 is fixed at the other end of the side body 11 . A binding strap 4 having a positioning strap hook fixedly connected to its outer end is coupled to the transverse shaft 12 of the bracket 1 . On the reel 3, another binding band 4 is wound on the outer end of which is fixed with a movable band hook. The bracket 1 is movably connected with a tooth blocking plate 6 whose end can be embedded between the ratchet teeth of the ratchet 5 , and the handle 2 is mova...

Embodiment 2

[0038] like Figure 7 As shown, in this embodiment, the sensor 8 is arranged on the above-mentioned binding band 4 , and the sensor 8 is connected with a wire 82 connected with the signal processing circuit 10 . When the binding device is in operation, the binding belt 4 is subjected to a tensioning force, and the sensor 8 provided on the binding belt 4 can easily detect the magnitude of the tensioning force, so as to grasp the working state of the binding device in time. The rest are similar to those in Example 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com