Non-return type hoister descending continuous speed regulation brake

A technology of stepless speed regulation and hoist, applied in the direction of the clockwork mechanism, hoisting device, etc., can solve the problems of enterprise shutdown, frequent damage, and difficulty in achieving speed control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

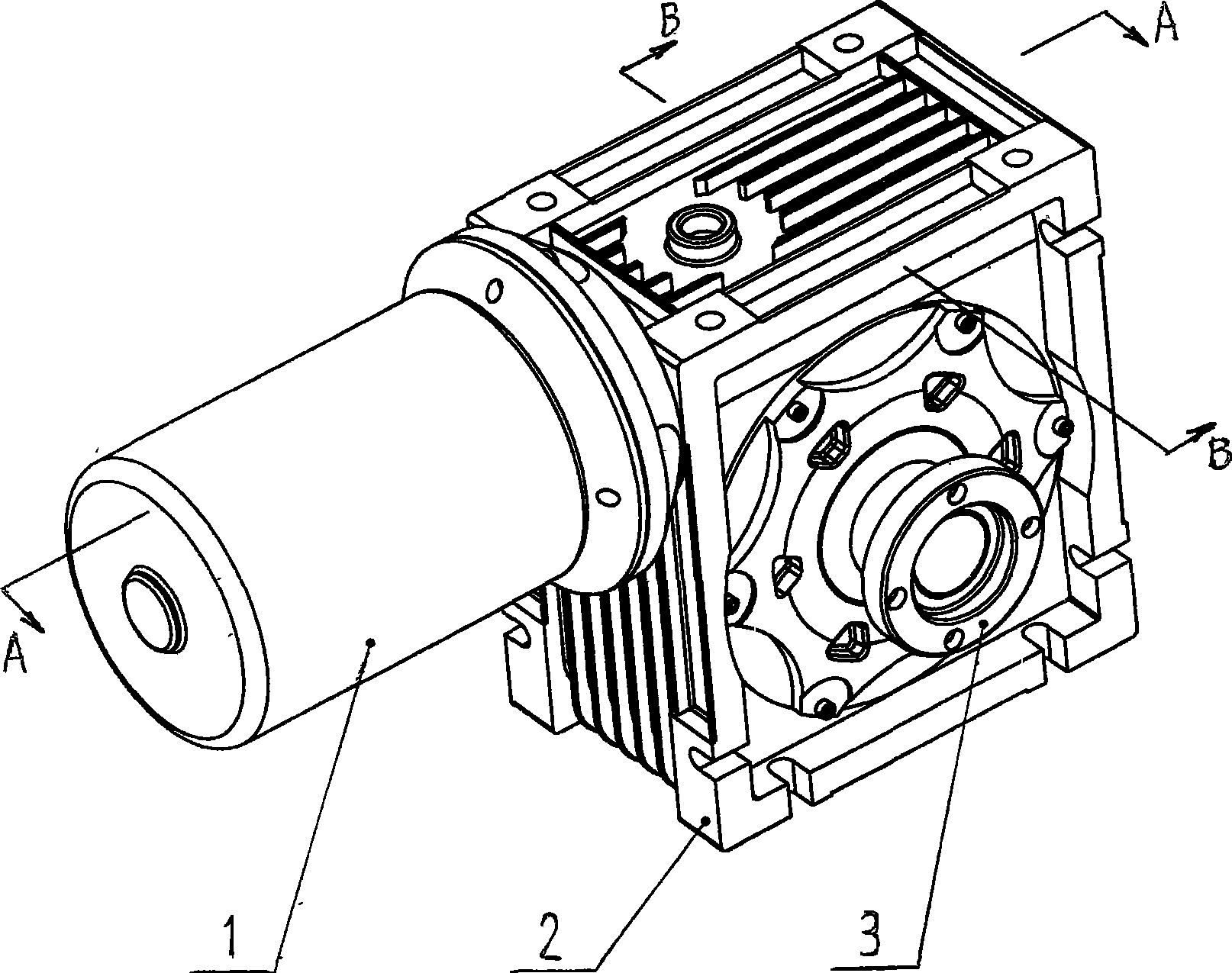

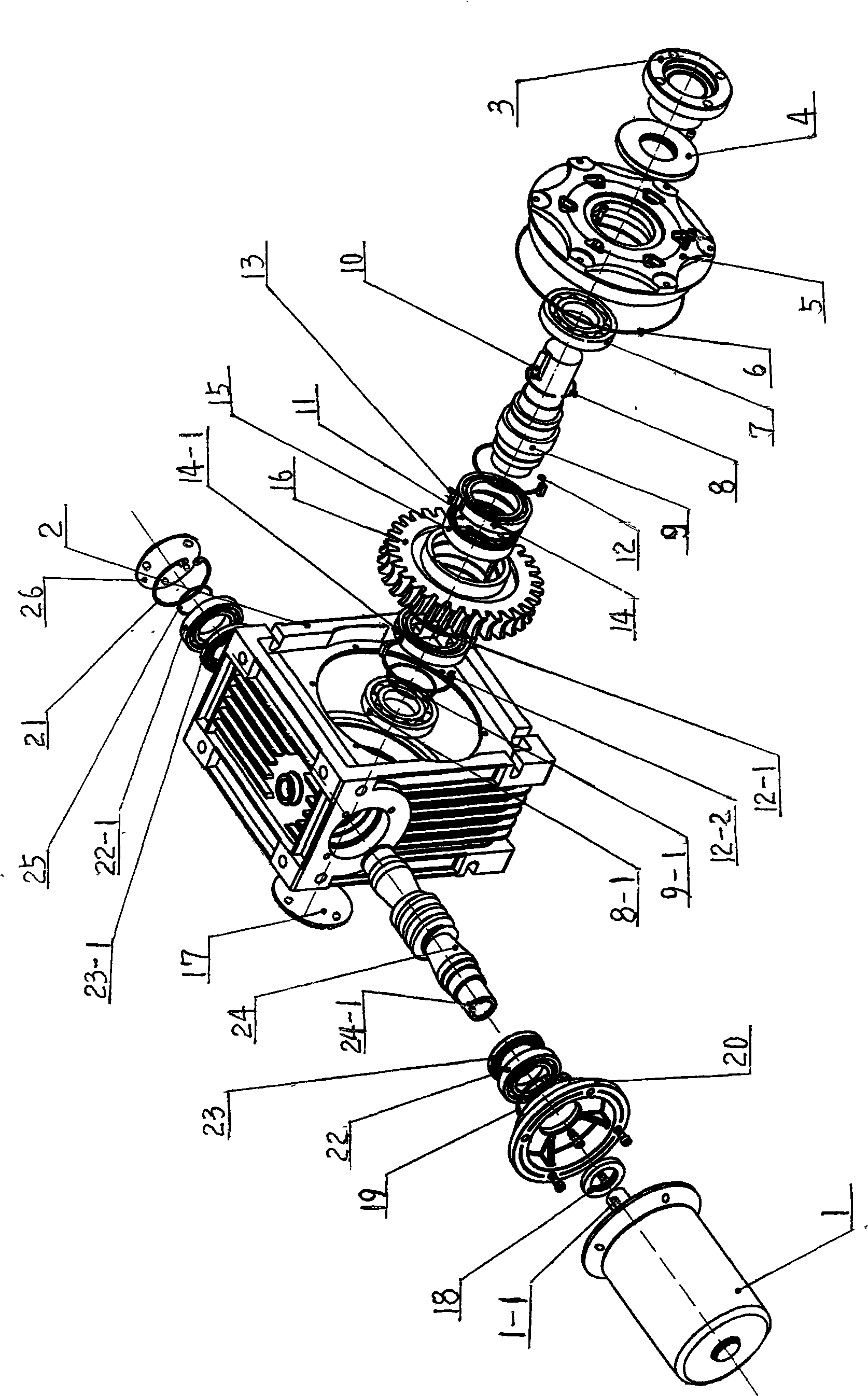

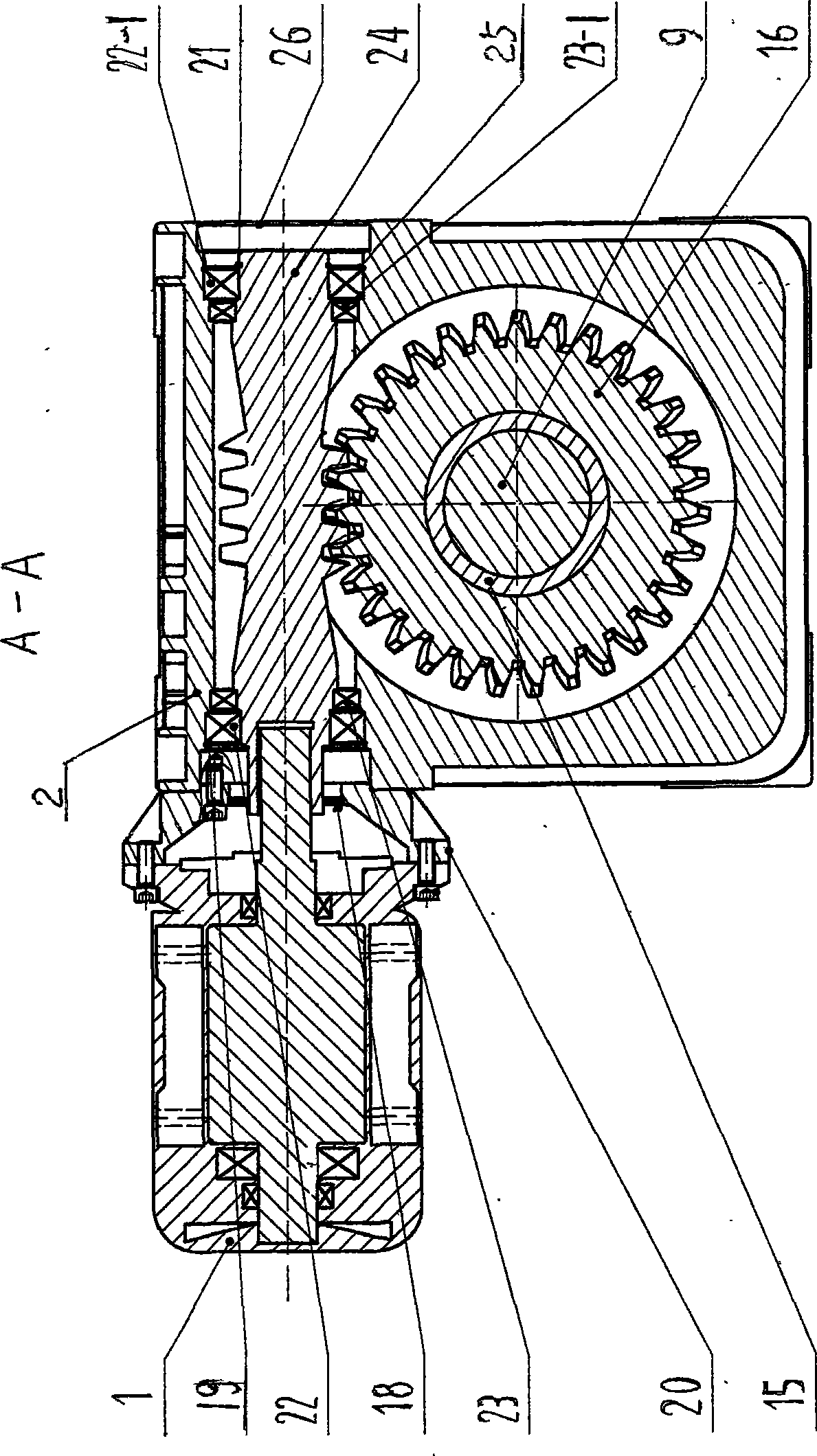

[0012] Examples, see attached Figure 1~4 , a worm 24 is installed in the middle of the upper end of the body 2 of the stepless speed regulation brake of the backstop type hoist. A keyway 24-1 is set in the middle, and a key 1-1 is provided on the motor output shaft to fix it. On the left side of the worm screw 24, a hole with a jumper 19, a worm bearing 22, and an axial bearing 23 are installed, and the left end of the hole with a jumper 19 is equipped with a motor flange 20, and the motor flange 20 uses a worm oil seal 18 and frequency conversion The brake motor 1 is fixed together, and the motor flange 20 is fixed on the body 2 with bolts. On the right side of the worm screw 24, axial bearing two 23-1, worm screw bearing two 22-1, shaft circlip 25, and hole circlip two 21 are arranged successively, and are covered with worm screw end cover 26, and worm screw end cover 26 is used Bolts are fixed on the body 2. The worm gear shaft 9 in the vertical direction at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com