Wellhead pressurization reciprocating type natural gas compressor unit

A technology of compressor unit and natural gas, which is applied in the direction of liquid variable-capacity machinery, mechanical equipment, variable-capacity pump components, etc., and can solve the problems of unattended operation, large investment of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

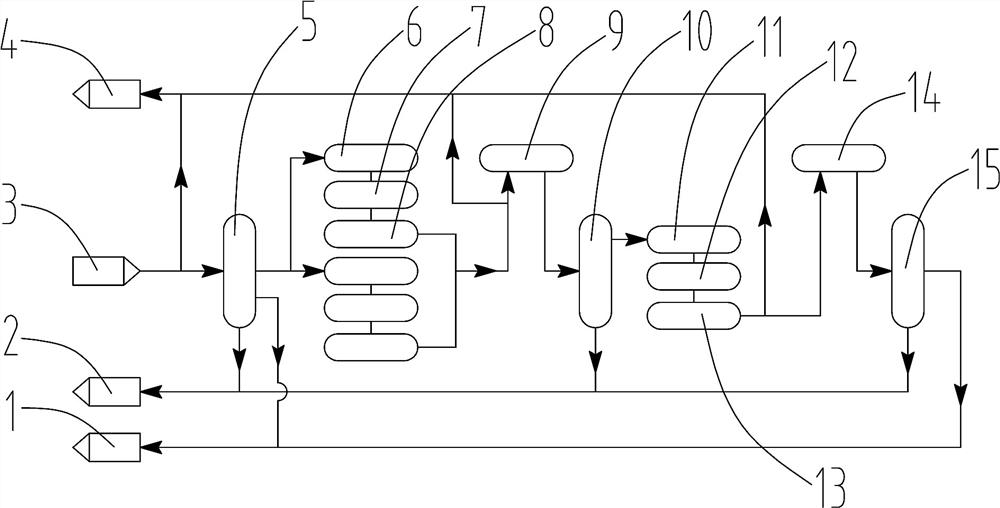

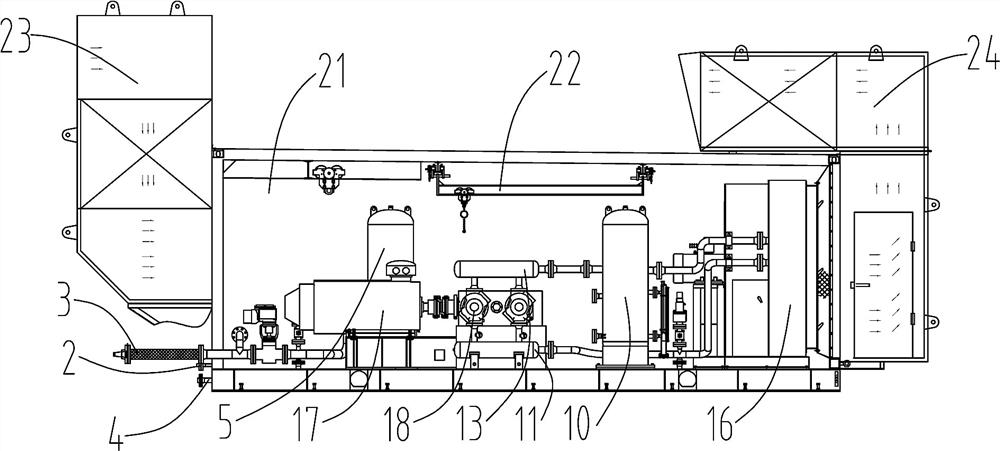

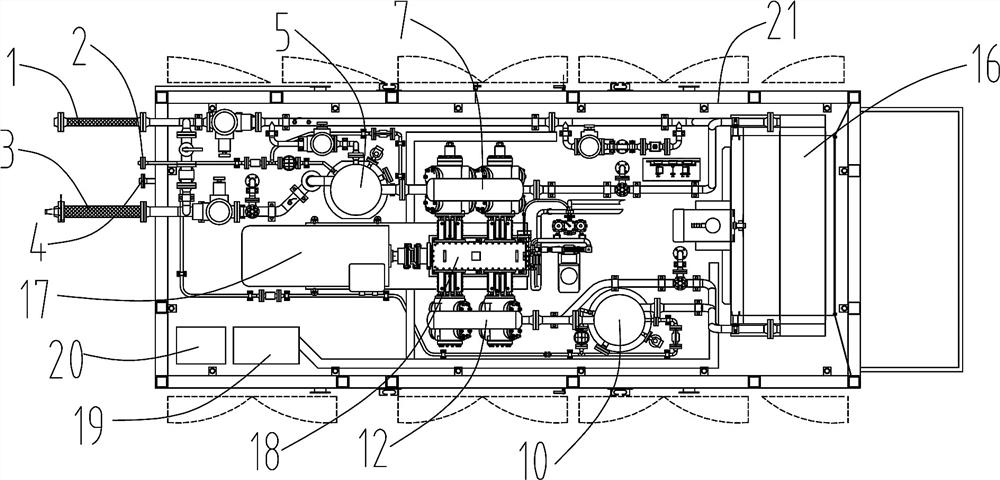

[0029] Such as Figure 1~4 As shown, the wellhead pressurized reciprocating natural gas compressor unit includes a skid-mounted noise reduction room 21, and the noise reduction room 21 is equipped with a compression separation cooling assembly, which is connected in series between the production pipeline and the storage pipeline. The intake pipeline 3 in the cooling assembly communicates with the production pipeline, the exhaust pipeline 1 communicates with the storage pipeline, and the pipeline connected between the intake pipeline 3 and the exhaust pipeline 1 is provided with a first-stage separator 5 and a first-stage compression cylinder connected in sequence 7. The secondary air cooler 14, the secondary separator 10, the secondary compression cylinder 12, the secondary air cooler 14 and the tertiary separator 15;

[0030] There is also a PLC control cabinet 19 and a power distribution box 20. The PLC control cabinet 19 is used to collect the pressure, temperature, separat...

Embodiment 2

[0043] Further illustrate in conjunction with embodiment 1, as Figure 1~4 As shown, the present invention designs a skid-mounted noise reduction room 21, a separator adapted to the wellhead gas, a reciprocating compressor host adapted to pressure and flow fluctuations, a process gas pipeline, a lubricating oil system, a venting system, a sound insulation room, The PLC control system and the sound and light alarm system realize the quick movement and quick installation of the unit, the allocation of gas volume at different wellheads, and the unattended unit. The technical solution of this invention takes the four-cylinder two-stage piston compression design as an example. The main engine of the reciprocating compressor adopts a completely symmetrical and balanced structure. Meet the needs of the unit to adapt to changes in wellhead pressure and gas volume. The unit adopts a skid-mounted noise reduction room 21. The sound insulation cover is installed on the base and is sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com