Epoxy solvent-free impregnating resin and preparation thereof

A technology of impregnating resin and epoxy resin, applied in the direction of plastic/resin/wax insulators, organic insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

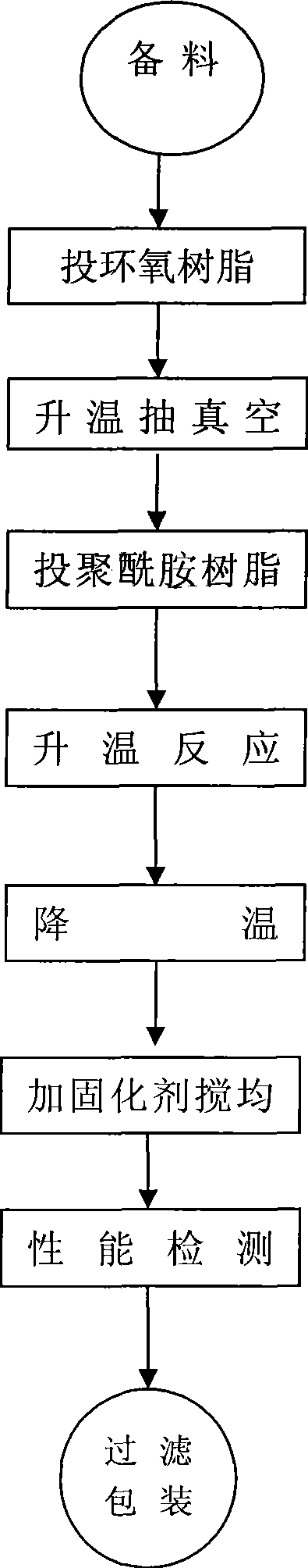

Method used

Image

Examples

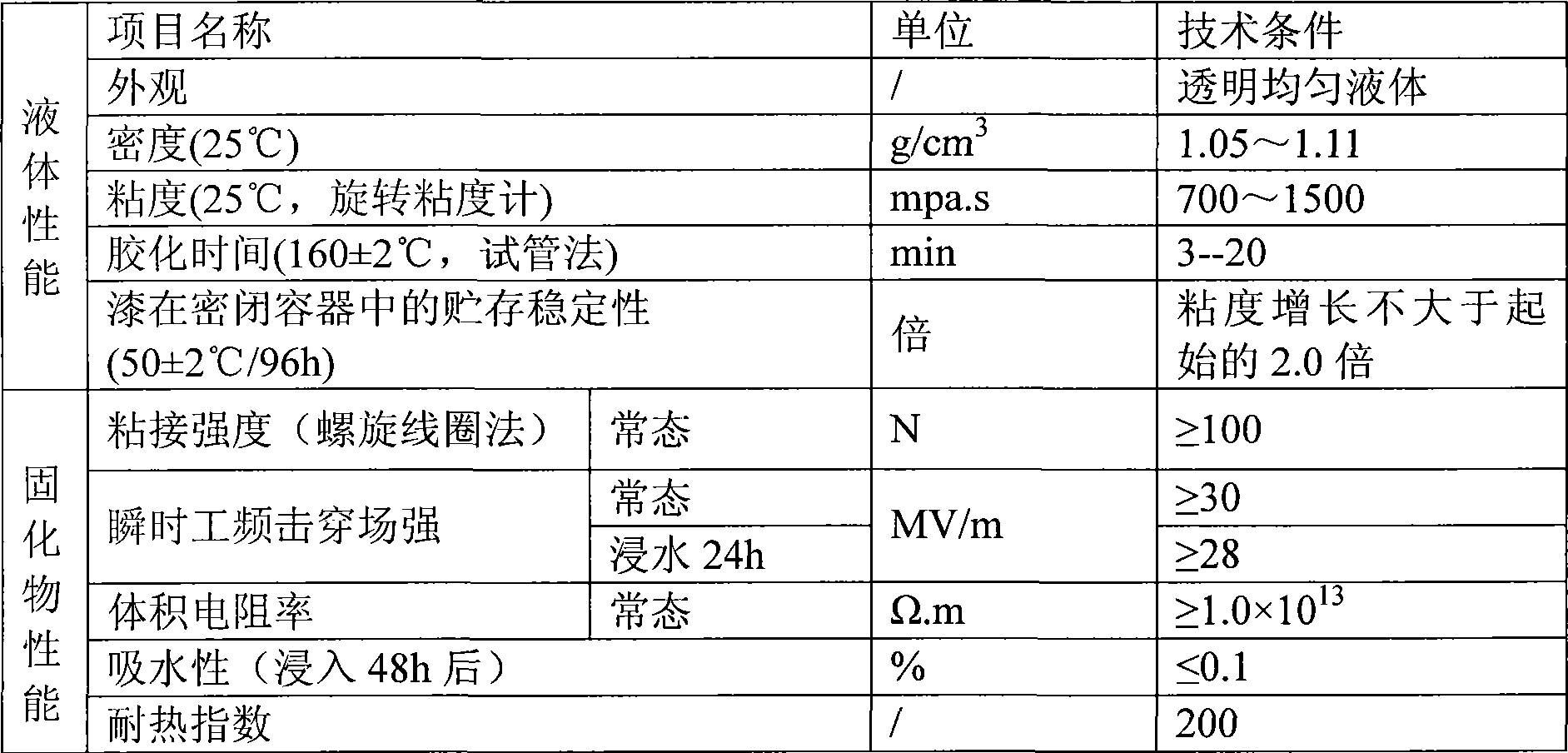

Embodiment 1

[0021] A 200-grade epoxy solvent-free impregnating resin, which is prepolymerized and modified by selecting bisphenol F epoxy resin, alicyclic epoxy resin and polyimide resin at 85°C for 3 hours. Add 50 parts of modified heat-resistant anhydride as curing agent to make epoxy anhydride solvent-free impregnating resin. Its characteristic is: the high temperature resistance of epoxy resin is improved by using the high temperature resistance of polyimide and alicyclic epoxy resin, and the insulation grade reaches above 200. Select heat-resistant acid anhydride and use metal salt and acid anhydride for complexation reaction to passivate it to form a relatively stable complex, so as to ensure that the epoxy resin and acid anhydride are stable at low temperature (normal) after mixing, and when it reaches a certain temperature Quick response. Due to the small molecular weight and low viscosity of bisphenol F epoxy resin, alicyclic epoxy resin and heat-resistant anhydride, after mixin...

Embodiment 2

[0035] A 200-grade epoxy solvent-free impregnating resin, which is prepolymerized and modified by selecting bisphenol F epoxy resin, alicyclic epoxy resin and polyimide resin at 110 ° C for 2.5 hours, and then adding 38 parts of modified heat-resistant acid anhydride is used as curing agent to make epoxy anhydride solvent-free impregnating resin. Its characteristic is: the high temperature resistance of epoxy resin is improved by using the high temperature resistance of polyimide and alicyclic epoxy resin, and the insulation grade reaches above 200. Select heat-resistant acid anhydride and use metal salt and acid anhydride for complexation reaction to passivate it to form a relatively stable complex, so as to ensure that the epoxy resin and acid anhydride are stable at low temperature (normal) after mixing, and when it reaches a certain temperature Quick response. Due to the small molecular weight and low viscosity of bisphenol F epoxy resin, alicyclic epoxy resin and heat-re...

Embodiment 3

[0049]A 200-grade epoxy solvent-free impregnating resin, which is prepolymerized and modified by selecting bisphenol F epoxy resin, alicyclic epoxy resin and polyimide resin at 120 ° C for 3.5 hours, and then adding 26 parts of modified heat-resistant acid anhydride is used as curing agent to make epoxy anhydride solvent-free impregnating resin. Its characteristic is: the high temperature resistance of epoxy resin is improved by using the high temperature resistance of polyimide and alicyclic epoxy resin, and the insulation grade reaches above 200. Select heat-resistant acid anhydride and use metal salt and acid anhydride for complexation reaction to passivate it to form a relatively stable complex, so as to ensure that the epoxy resin and acid anhydride are stable at low temperature (normal) after mixing, and when it reaches a certain temperature Quick response. Due to the small molecular weight and low viscosity of bisphenol F epoxy resin, alicyclic epoxy resin and heat-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com