Temperature sensor

A technology of temperature sensor and protection tube, used in thermometers, thermometer parts, instruments, etc., can solve the problems of low thermal conductivity of ceramic powder, no ceramic powder, and high response time of temperature sensor, so as to shorten the response time and shorten the response time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

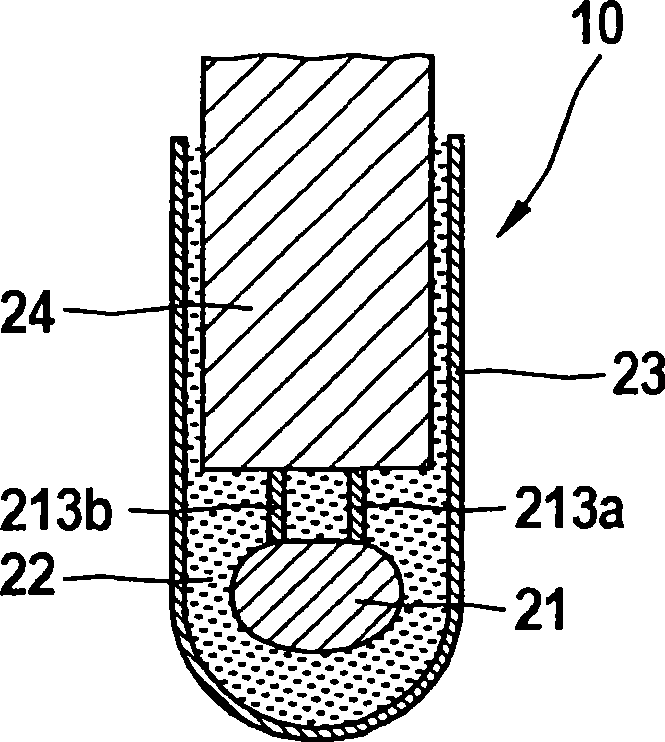

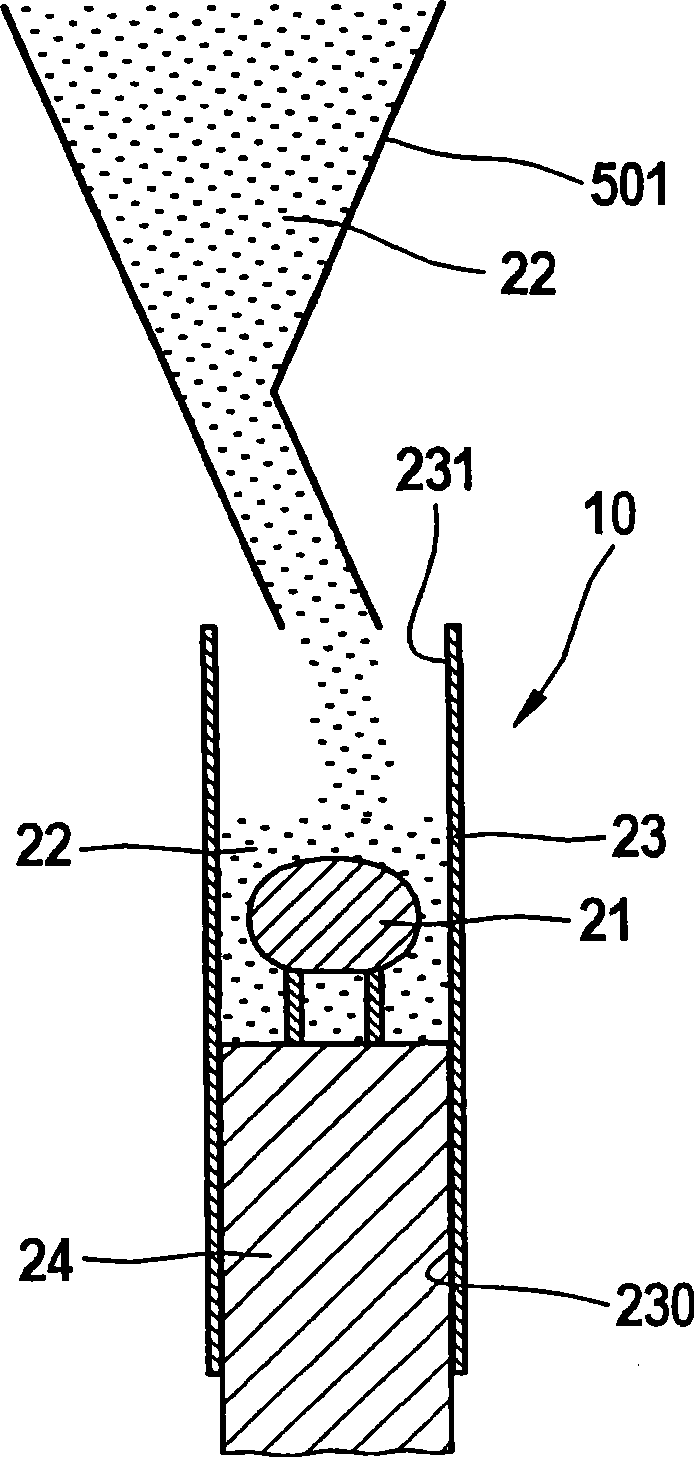

[0019] figure 1 A temperature sensor 10 according to the invention is shown. The temperature sensor 10 includes a thermal sensor 21 , ceramic powder 22 and a protective casing 23 . The thermosensitive element 21 is fixed and insulated in a protective housing 23 by means of compacted ceramic powder 22 . In addition, the temperature sensor 10 also has a closure element 24 whose task is to fill the cross-section of the protective tube 23 and thus seal the protective tube.

[0020] The thermal element 21 is a temperature-dependent resistor, such as an NTC resistor (thermistor with a negative temperature coefficient) or a PTC resistor (thermistor with a positive temperature coefficient).

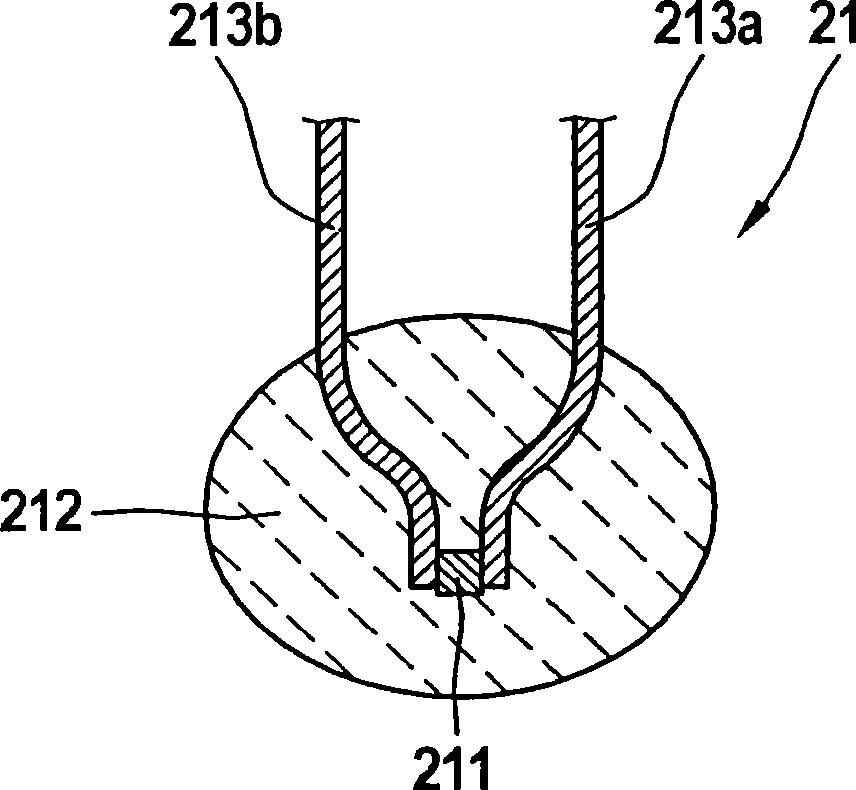

[0021] exist figure 1 In a, the structure of the thermosensitive element 21 is shown. The thermosensitive element 21 has a resistor 211, which includes a semiconductor material such as Fe 2 o 3 , ZnTiO 4 or MgCr 2 o 4 . The resistance element 211 determines the temperature-resistance ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com