Wireless video automatic monitoring system for pantograph of locomotive

An automatic monitoring system and wireless video technology, applied in the direction of the fault location, etc., can solve the problems of inability to observe the working face of the pantograph, large locomotive shaking, and low image accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

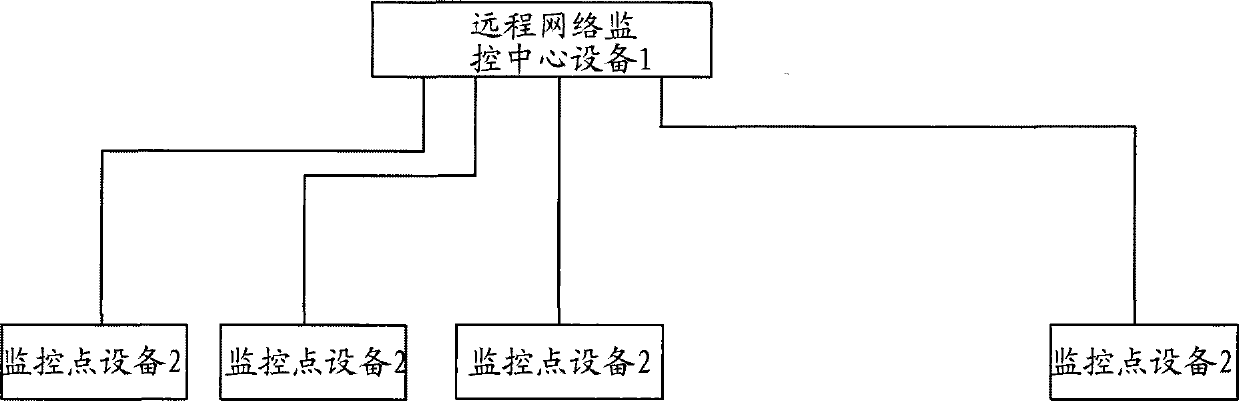

[0019] figure 1 It is a functional block diagram of the wireless video automatic monitoring system for the locomotive pantograph of the present invention. Such as figure 1 As shown, the locomotive pantograph wireless video automatic monitoring system proposed by the present invention includes a remote network monitoring center device 1 and several monitoring point devices 2 . The remote network monitoring center device 1 realizes remote monitoring of the monitoring point device 2 through a wireless network. The quantity of monitoring point equipment 2 can be determined by the user according to the actual situation of needs, installation lines and capital situation.

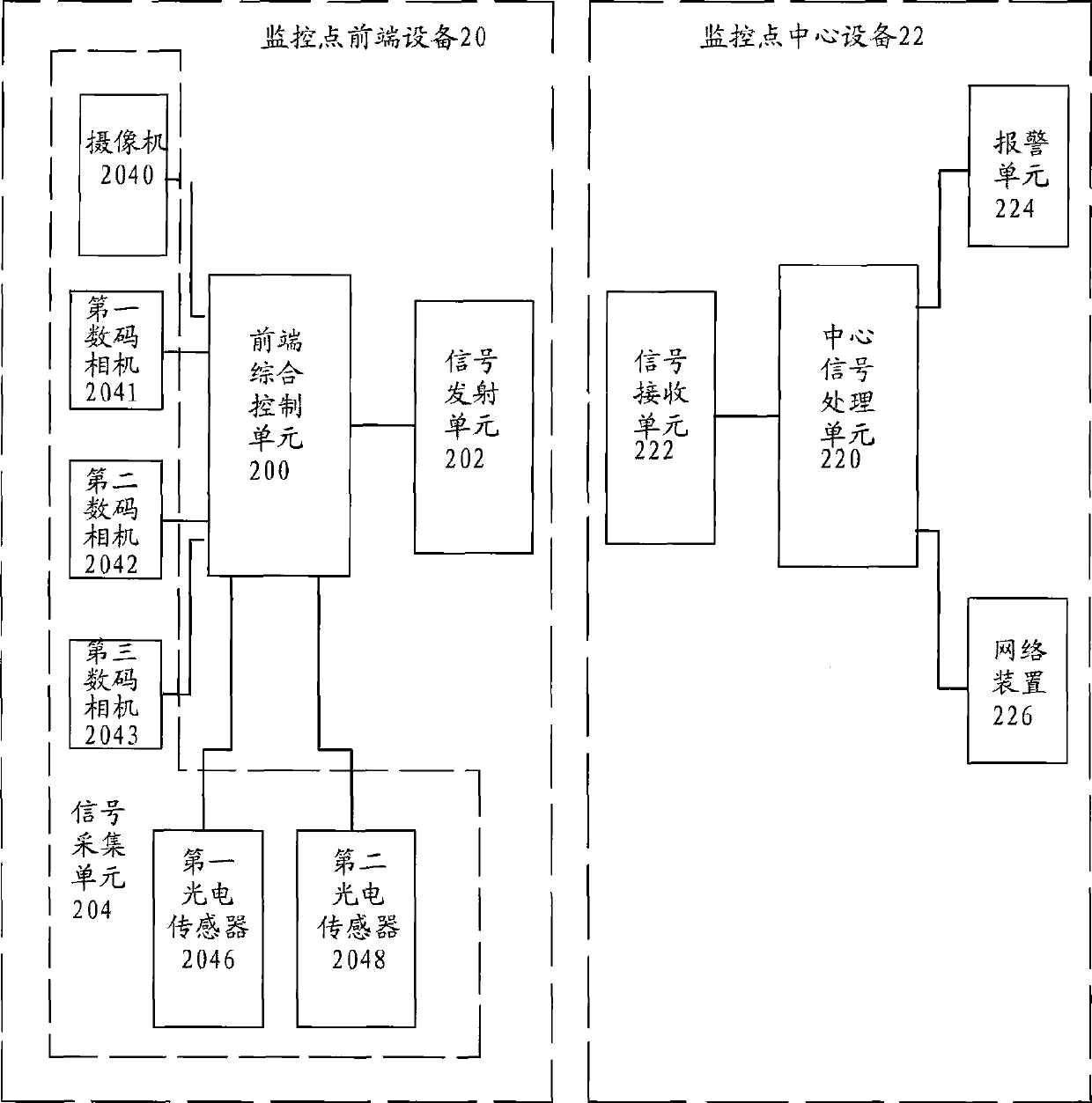

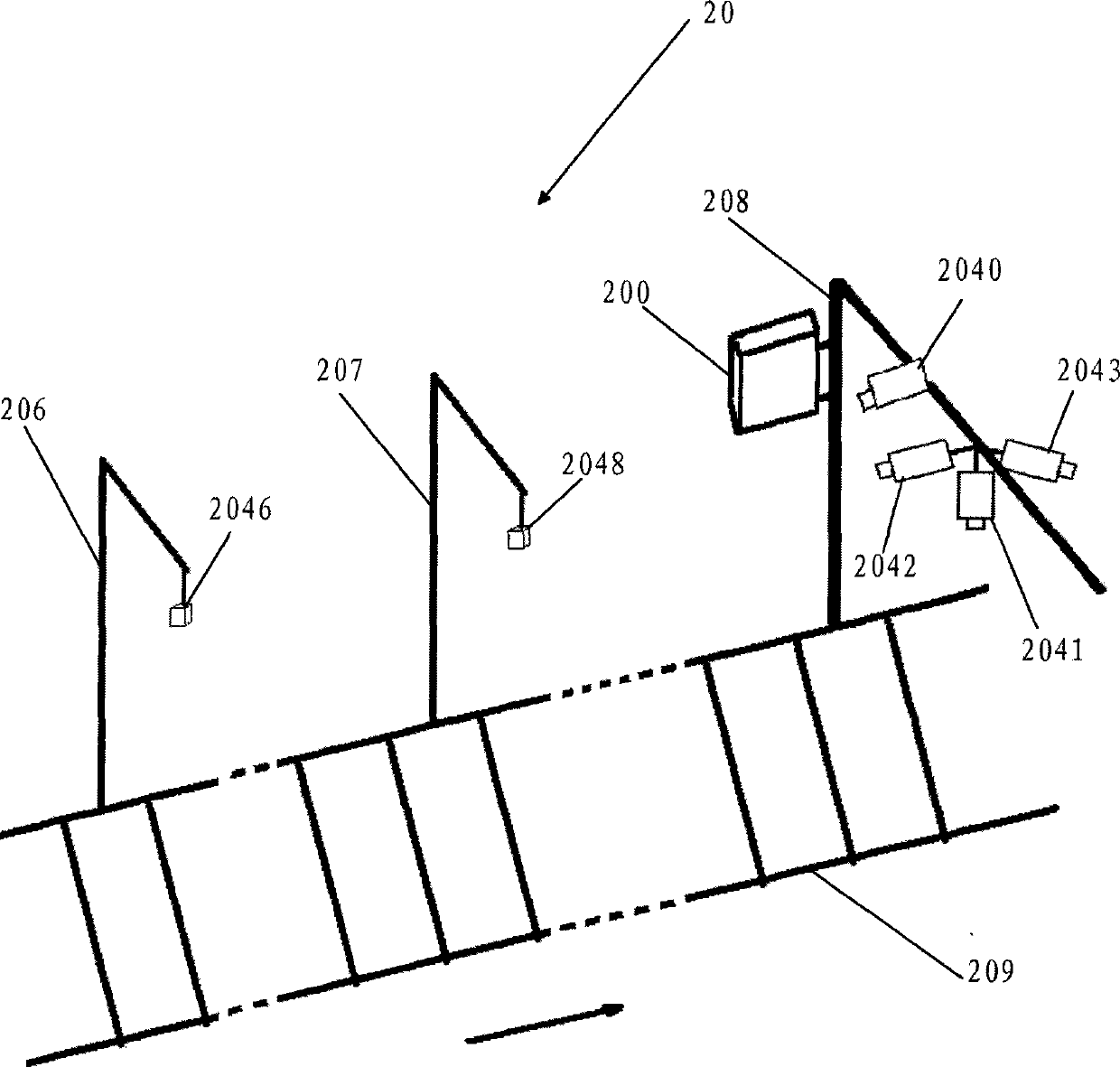

[0020] figure 2 for figure 1 Schematic block diagram of the monitoring point device shown. Such as figure 2 As shown, the monitoring point device 2 includes a monitoring point front-end device 20 and a monitoring point central device 22, and the monitoring point front-end device 20 and the monitoring point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com