Polarizing film with adhesive, optical laminate, and set of polarizing films

A technology for optical laminates and polarizing films, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as insufficient durability and low gel percentage, Achieves the effect of suppressing foaming and excellent recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

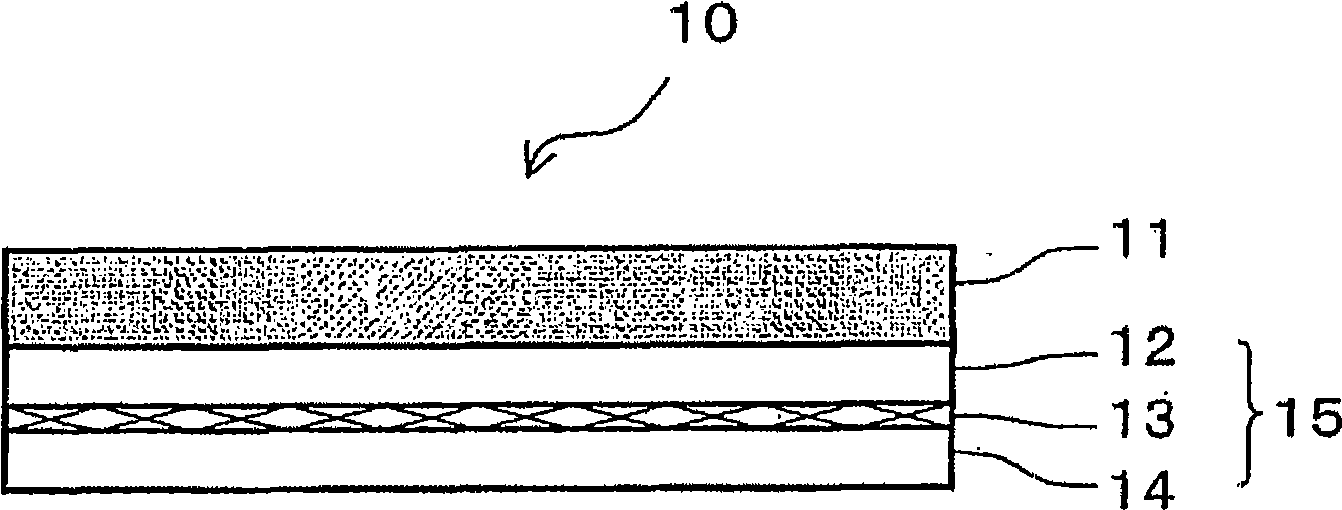

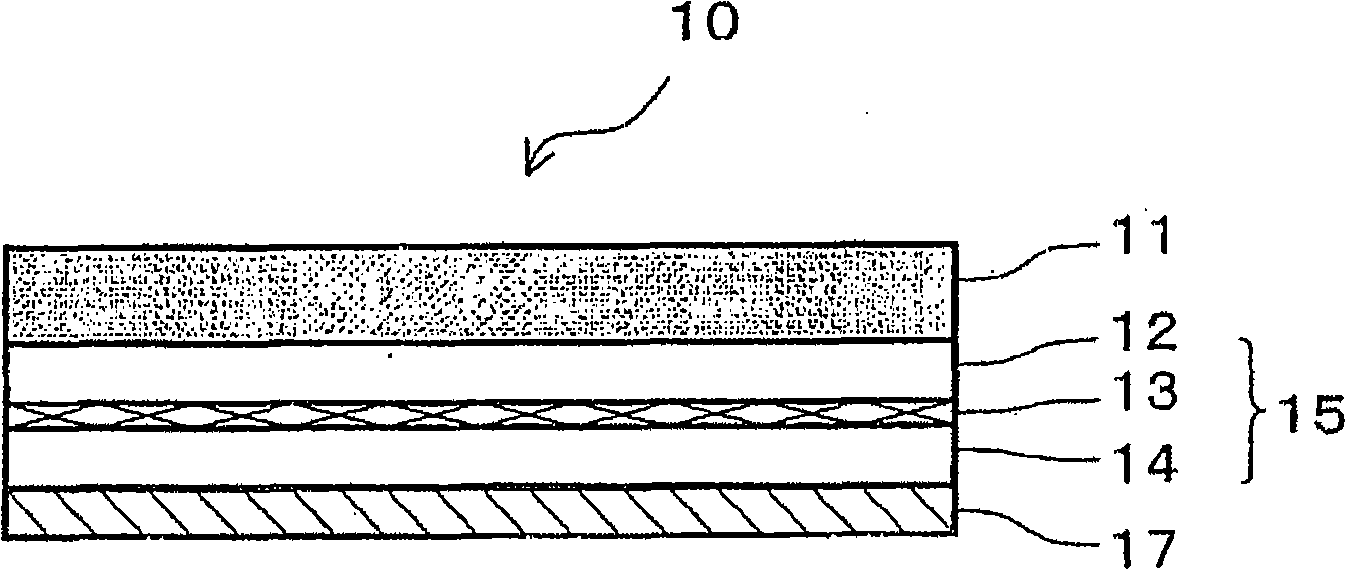

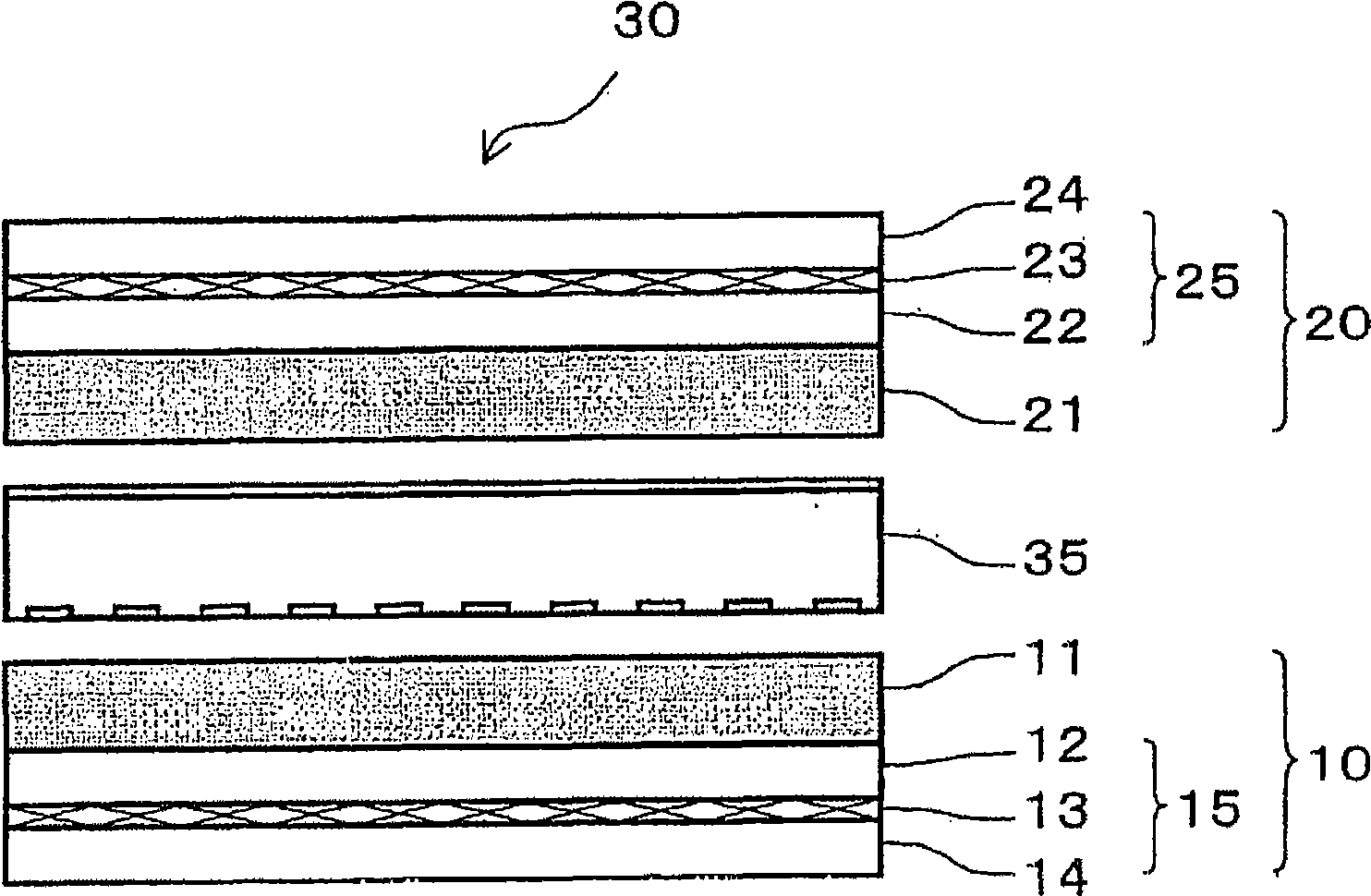

[0134] For the first embodiment of the optical laminate, in the main reference image 3 , and optionally also refer to Figure 4 while explaining. In this mode, it is preferable to sandwich the first polarizing film 15 formed by the composition of amorphous cyclic polyolefin resin film 12 / polarizer 13 / protective film 14 between the amorphous cyclic polyolefin resin On the side of the film 12, the first adhesive layer 11 with a gel percentage of 75% to 95% by weight is bonded to one side of the glass unit 35 for liquid crystal display, and on the other side of the glass unit 35 for liquid crystal display, the second adhesive layer is sandwiched between The second adhesive layer 21 is attached to the second polarizing film 25 formed by attaching acetylcellulose-based protective films 21, 23 on both sides of the polarizer 23, and the gel percentage of the second adhesive layer 21 reaches 30% by weight. ~70% by weight.

[0135] In this form, although it is arbitrary which of th...

no. 2 approach

[0145] Next, for the second embodiment of the optical laminate, still mainly refer to image 3 , and optionally also refer to Figure 4 while explaining. In this mode, the first polarizing film 15 formed by the composition of the amorphous cyclic polyolefin resin film 12 / polarizer 13 / protective film 14 is interposed between the amorphous cyclic polyolefin resin film 12. On the other side, the first adhesive layer 11 with a gel percentage of 75% to 95% by weight is laminated on one side of the glass unit 35 for liquid crystal display. On the other side of the glass unit 35 for liquid crystal display, an amorphous ring The second polarizing film 25 formed by the composition of polyolefin-based resin film 22 / polarizer 23 / protective film 24 sandwiches the non-crystalline cyclic polyolefin-based resin film 22 side and has a gel percentage of 75% by weight. -95% by weight of the second adhesive layer 21 is laminated.

[0146] For the second polarizing film 25 of this mode, it is ...

manufacture example 1

[0186]With respect to 100 parts of the non-volatile content of the acrylic resin A1 obtained in Polymerization Example 1, 5 parts of the crosslinking agent "Colonate L" was mixed as a solid content, and 0.1 part of the silane compound "X-41-1805" was mixed to prepare binder solution. This adhesive solution was coated on a release film of a polyethylene terephthalate film [trade name "PET3811", purchased from Lintec Co., Ltd.; referred to as a separator] that had undergone release treatment using an applicator. The mold-treated surface was dried to a thickness of 15 μm after drying at 100° C. for 1 minute to obtain a sheet-like adhesive. Let this be Adhesive 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com