Alarming method for preventing anti-explosion fire-fighting pressure air-bottle from fault deflation

A pressure and gas cylinder technology, applied in fire rescue and other directions, can solve problems such as accidental loss, deformation, and direct or indirect mechanical external force, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

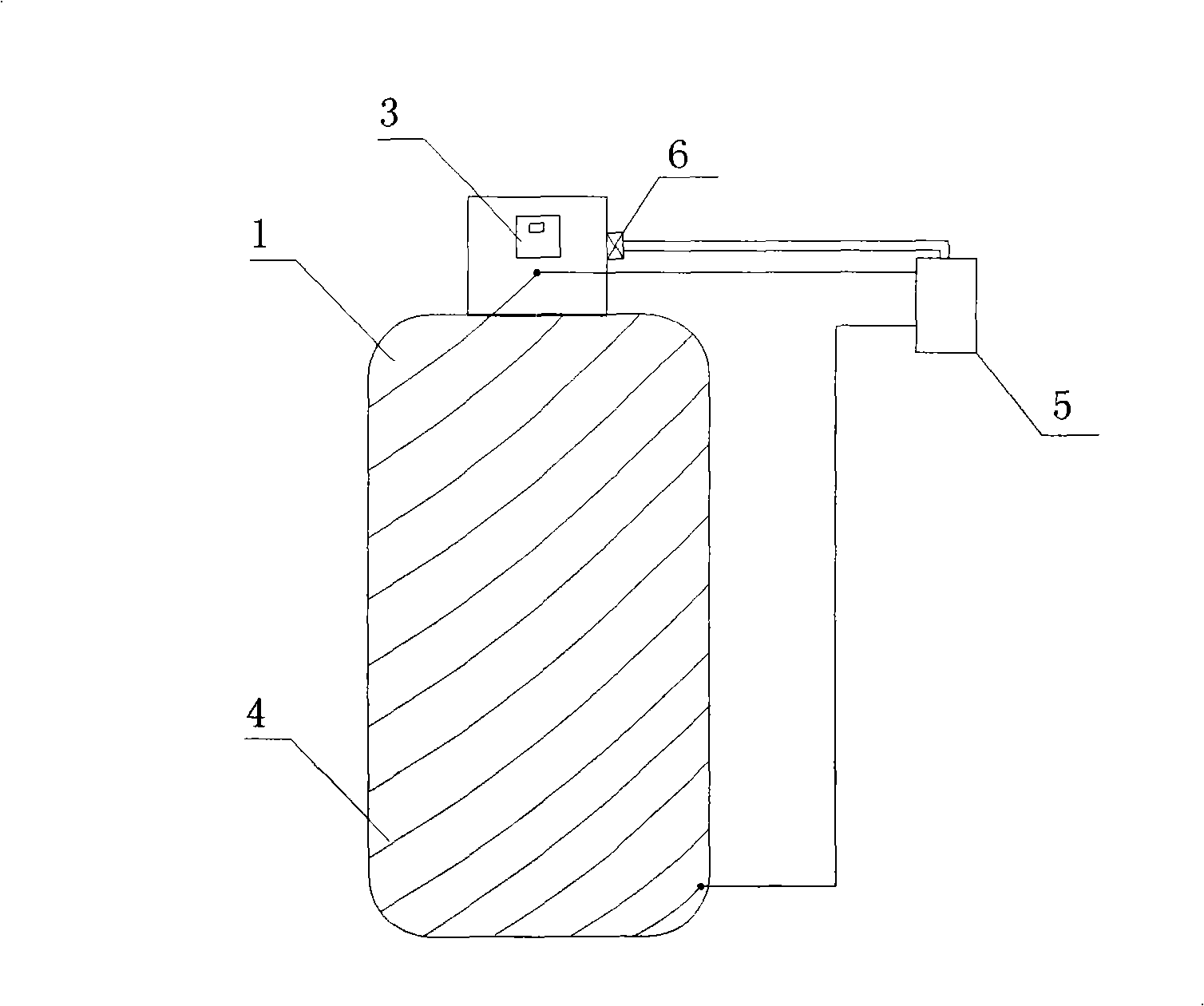

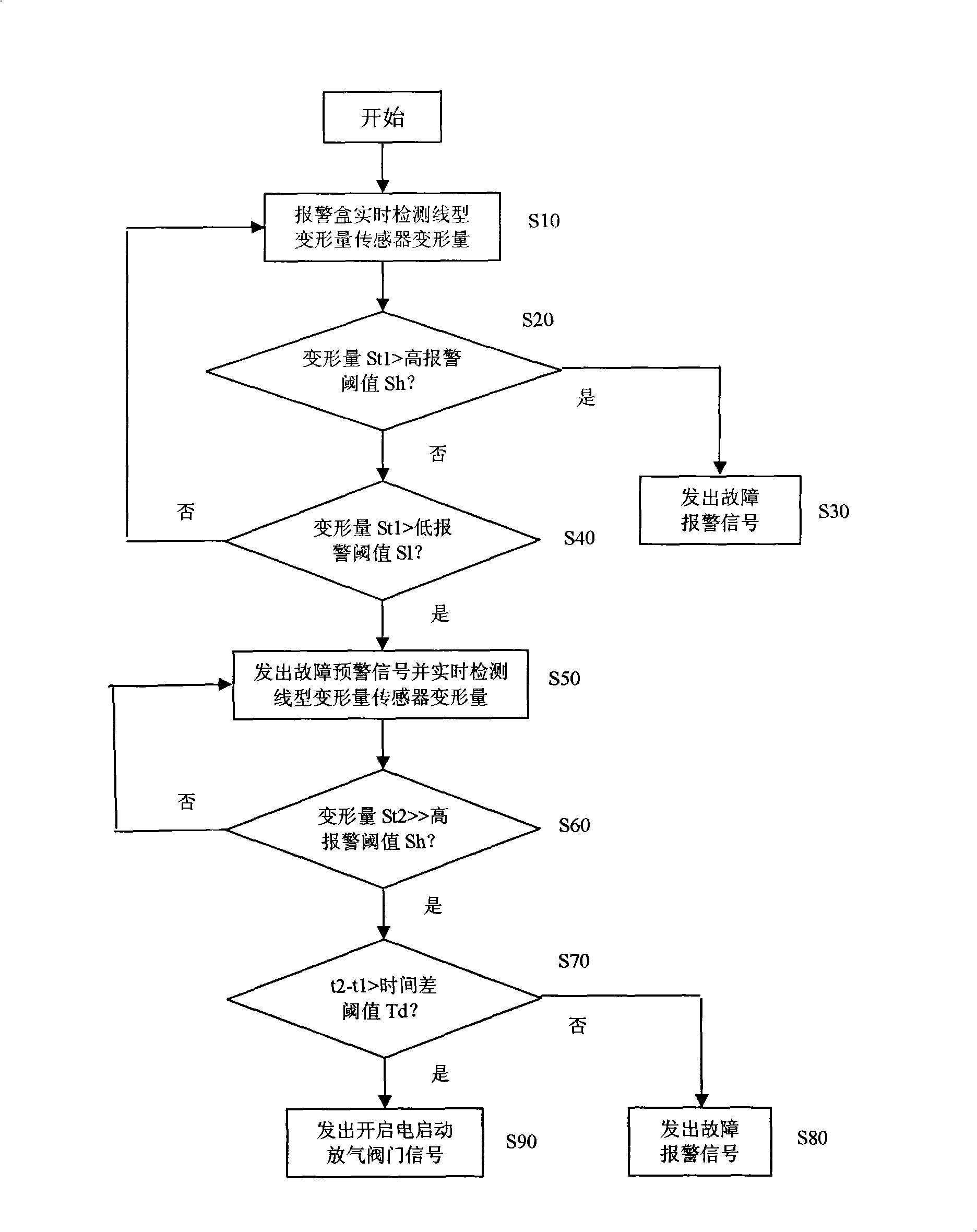

[0046] like figure 2 and figure 1 As shown, the fire-fighting pressure gas cylinder in the alarm method for preventing the explosion-proof fire-fighting pressure gas cylinder from being deflated by the present embodiment mainly includes a steel cylinder 1, a fire extinguishing agent or driving gas stored in the steel cylinder 1, and a gas cylinder installed in the steel cylinder 1. At the opening of the upper end, a container valve 3 for sealing the fire extinguishing agent or driving gas stored in the steel cylinder 1, a linear deformation sensor 4 with strain effect wound on the outer wall of the steel cylinder 1 at intervals, and a linear deformation sensor 4 with a linear The measurement end of deformation sensor 4 is connected, is used for measuring deformation and the alarm box 5 that sends alarm signal and one is electrically connected with alarm box 5 and is installed in the opening of steel cylinder 1, and its inlet is connected with the inside of steel cylinder 1, a...

Embodiment 2

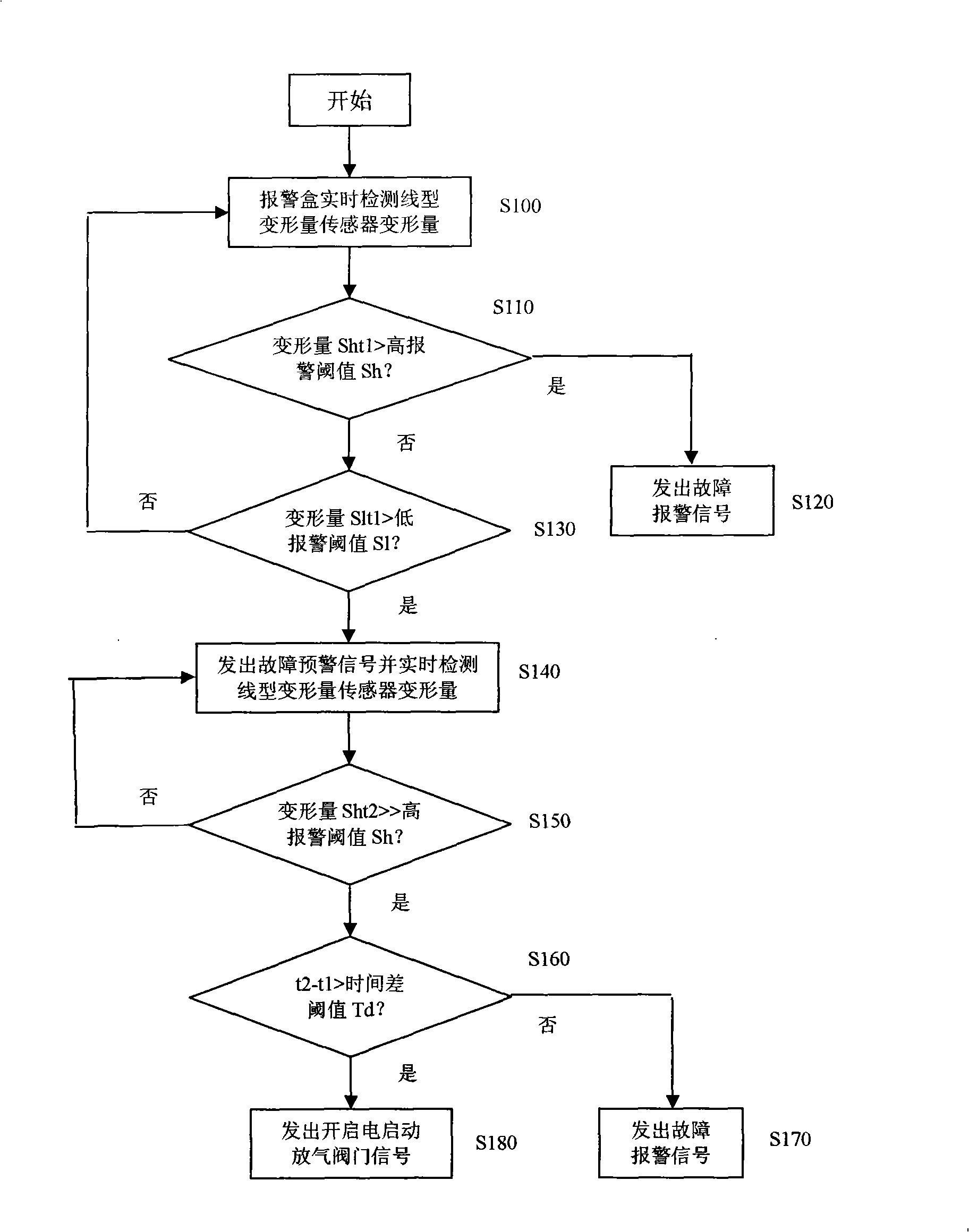

[0070] like image 3 and figure 1 As shown, the fire-fighting pressure gas cylinder in the alarm method for preventing the explosion-proof fire-fighting pressure gas cylinder from being deflated by the present embodiment mainly includes a steel cylinder 1, a fire extinguishing agent or driving gas stored in the steel cylinder 1, and a gas cylinder installed in the steel cylinder 1. The opening of the upper end is used to seal the fire extinguishing agent or driving gas container valve 3 stored in the steel cylinder 1, and two low-plastic linear deformation sensors H and L wound on the outer wall of the steel cylinder 1 at intervals. The measuring ends of the low-plastic linear deformation sensors H and L are connected to each other, an alarm box 5 for measuring the deformation and sending an alarm signal, and one is electrically connected with the alarm box 5 and installed at the opening of the steel cylinder 1, and its inlet is connected to the steel cylinder The interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com