Free-forging shortening method and anvil at ultralimit aspect ratio

A high-diameter ratio, ultra-limited technology, used in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as difficult control of ingot metallurgical quality

Inactive Publication Date: 2009-07-29

SOUTHWEST ALUMINUM GRP

View PDF0 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] With the development of aviation and aerospace industry, aluminum alloy forgings are developing in the direction of large-scale and integrated. For this purpose, the task of providing larger and heavier aluminum alloy forgings is in front of us. constraints, and it is impossible to make large aluminum alloy round ingots in a short period of time. At present, Southwest Aluminum can only provide 820mm qualified aluminum alloy round ingot, in addition, with the increase of the cross-sectional size of aluminum alloy ingot, the metallurgical quality of the ingot is more difficult to control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

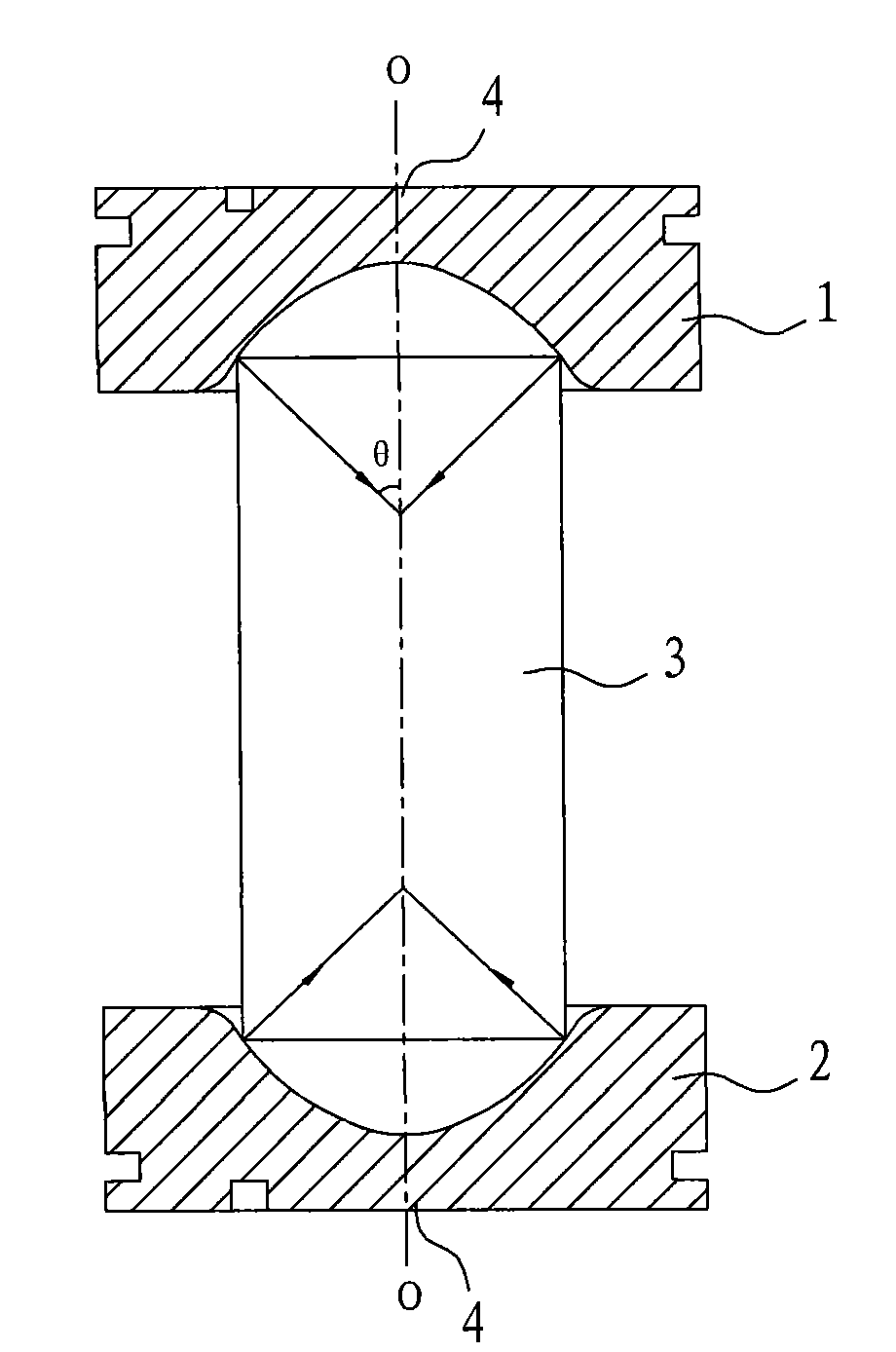

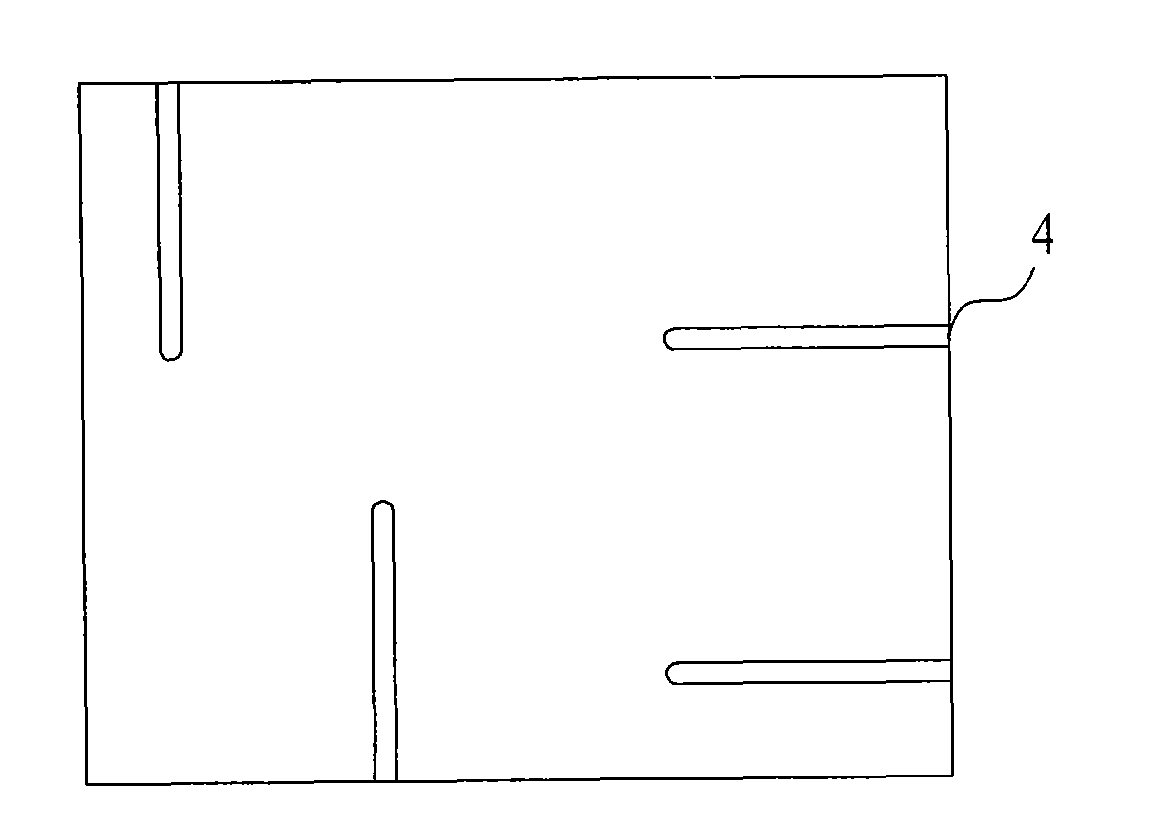

The invention discloses a flat die forging high slenderness ratio ultralimit upsetting method and a flat die forging high slenderness ratio ultralimit upsetting anvil. The upsetting method comprises the following steps: positioning an upper concave anvil and a lower concave anvil, and guaranteeing superposition of a central line of the upper concave anvil and a central line of the lower concave anvil; suspending circular cast ingots of which the slenderness ratio is more than 3 on the lower concave anvil, and adjusting the position to guarantee superposition of central lines of the aluminum alloy circular cast ingots, the central line of the upper concave anvil and the central line of the lower concave anvil; and allowing a power mechanism to drive the upper concave anvil to move down after the adjustment is over, and slowly applying pressure on the aluminum alloy circular cast ingots, so that the aluminum alloy circular cast ingots are stably upset and do not have the defects of bending, folding and the like. The invention breaks through impassable rules of aluminum alloy upsetting in the recent hundred years, and makes the slenderness ratio of the aluminum alloy circular cast ingots be more than 3 and reach 3.3 (phi 820*2,700mm), namely the length of the circular cast ingots increases 240 mm and the weight of the circular cast ingots increases 360 kg after the length of phi 820 mm circular cast ingots increases from 2,460 mm to 2,700 mm, so that the invention provides enough metal margin and creates a loose environment for development of aluminum alloy annular forged pieces.

Description

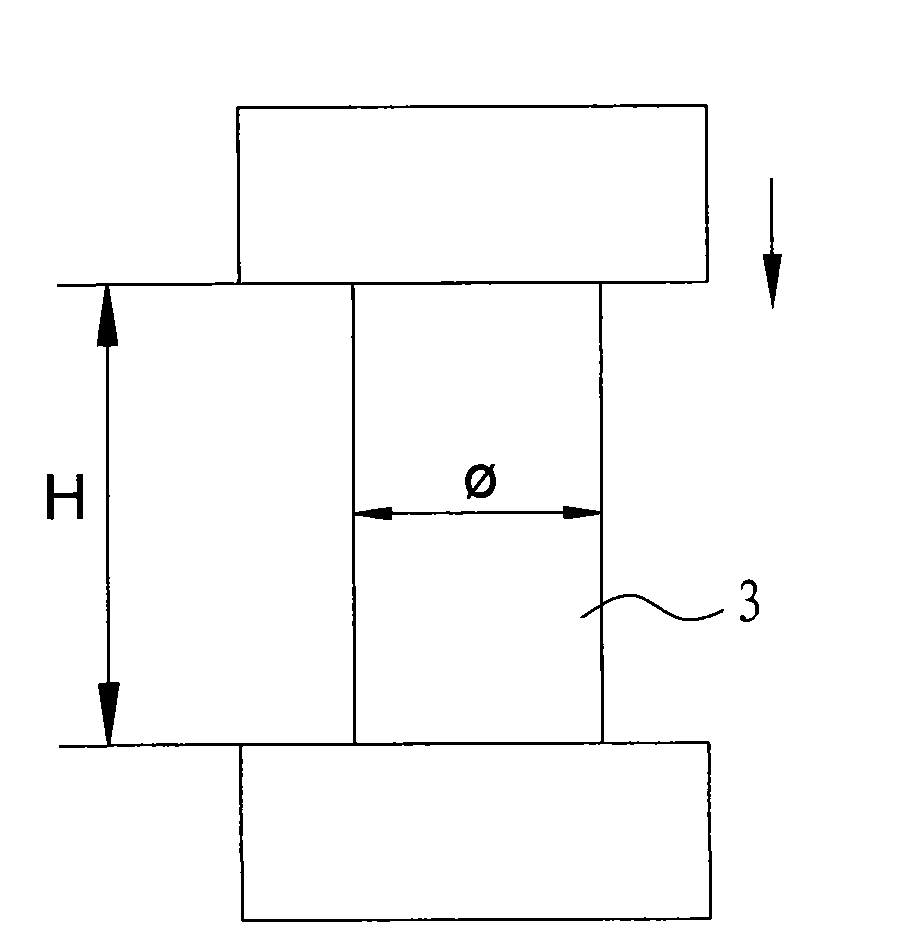

technical field [0001] The invention relates to an upsetting method and an anvil for aluminum alloy forgings in free forging, and belongs to the field of aluminum alloy processing. Background technique [0002] The blanks used in large aluminum alloy forgings are generally round ingots. In order to improve the internal structure and performance of the forgings, obtain a certain shape and size, and provide ideal blanks for the subsequent production of die forgings or rolled ring forgings, it is often necessary to Round ingots are used for forging blanks, and upsetting is the most important process in forging blanks. The traditional free forging and upsetting methods are as follows: figure 1 As shown, this upsetting method, due to the limitation of stability conditions, when H (or L) is greater than 3 , the original aluminum alloy ingot 5 will be bent during the rough forging process, and will eventually be folded, resulting in scrapping and failing to produce a forging blan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21J5/08B21J13/06

Inventor 钟诚道林海涛王献文王勇罗顺成李先伟

Owner SOUTHWEST ALUMINUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com