Solid phase support crosslinking enzyme aggregation and method for preparing the same

A technology of aggregates and cross-linked enzymes, applied to biochemical equipment and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc., can solve problems such as inability to recycle and reuse, and achieve Easy optimization of reaction conditions, simple method, and the effect of high liquid flow rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

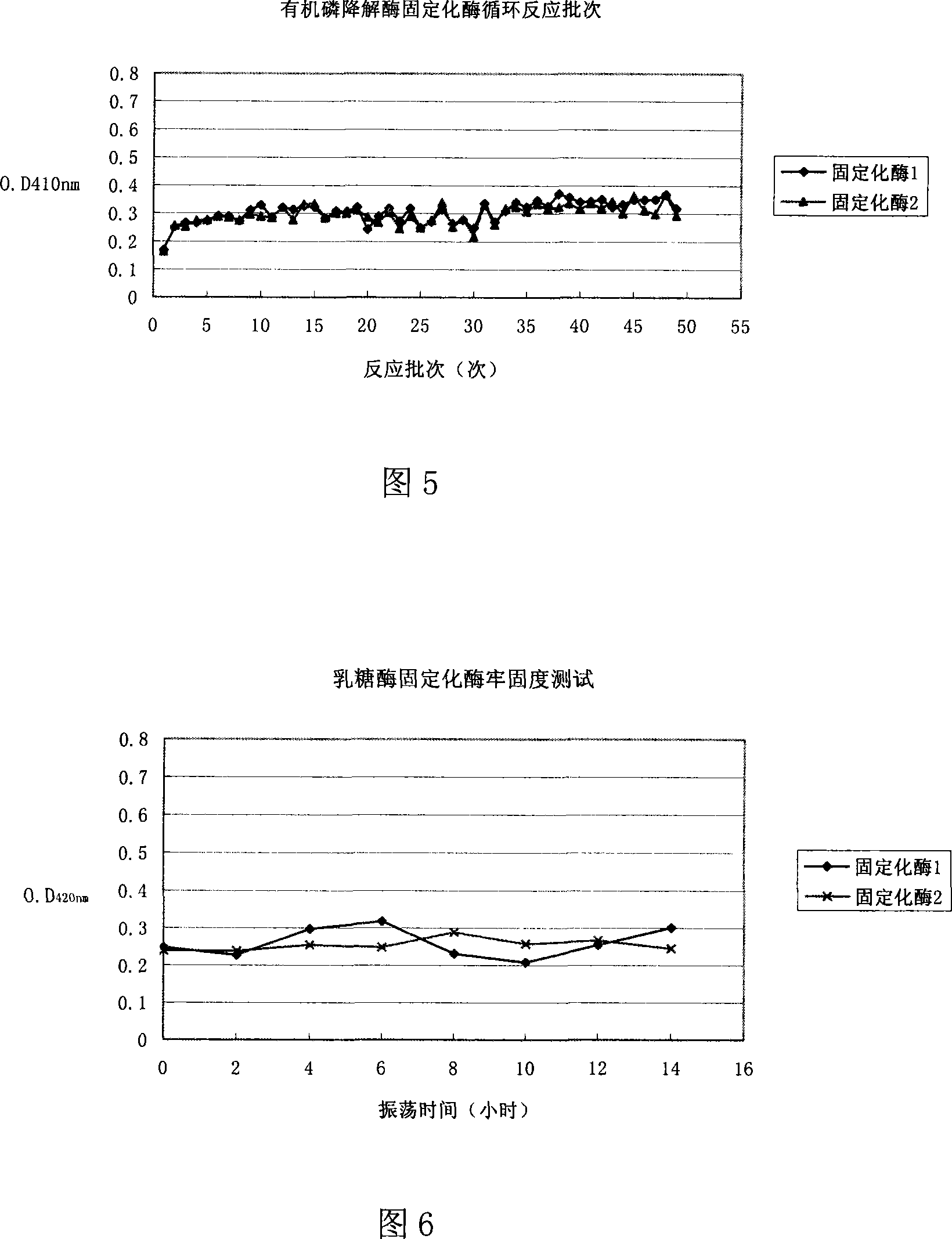

[0027] Example 1 Preparation of immobilized cross-linked organophosphate degrading enzyme aggregates

[0028] Weigh the organophosphorus degrading enzyme and dissolve it in phosphate buffer solution to prepare an enzyme solution with a protein concentration of 0.4 mg / ml, and add porous microspheres (polystyrene type non-polar adsorption resin, model ADS-5; average pore diameter The particle size is 30nm and the particle size is greater than 100μm; performance: it does not adsorb proteins, sugars, inorganic acids, alkalis, salts, and small-molecular hydrophilic organic substances; it has high resistance to heat, acid, alkali, organic solvents, etc. Stability. Tianjin Nankai Hecheng Science and Technology Co., Ltd. formula), stirred slowly at 4°C for 3 hours; then added ammonium sulfate to a saturation of 67.5%, stirred slowly at 4°C for 5 hours; added glutaraldehyde (25%) The solution was stirred slowly at 4°C for 18 hours to a final concentration of 2.2%; the porous microspher...

Embodiment 2

[0030] Weigh lactase and dissolve it in phosphate buffered saline, prepare an enzyme solution with a protein concentration of 0.5 mg / ml, add porous microspheres (polystyrene type non-polar adsorption resin, model is ADS-5. The average pore size is 30nm , the particle size is greater than 100 μm; performance: it does not adsorb proteins, sugars, inorganic acids, alkalis, salts, and small-molecular hydrophilic organic compounds; it has high stability under conditions such as heat, acid, alkali, and organic solvents (produced by Tianjin Nankai Hecheng Technology Co., Ltd.), and stirred slowly at 4°C for 3 hours. Add ammonium sulfate to a saturation of 67.5%, and stir slowly at 4°C for 5 hours. Add glutaraldehyde (25%) solution to a final concentration of 2.2%, and stir slowly at 4°C for 18 hours. The porous microspheres were taken out by filtration, and rinsed repeatedly until the solution was clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com