Solid phase support crosslinking enzyme aggregation and method for preparing the same

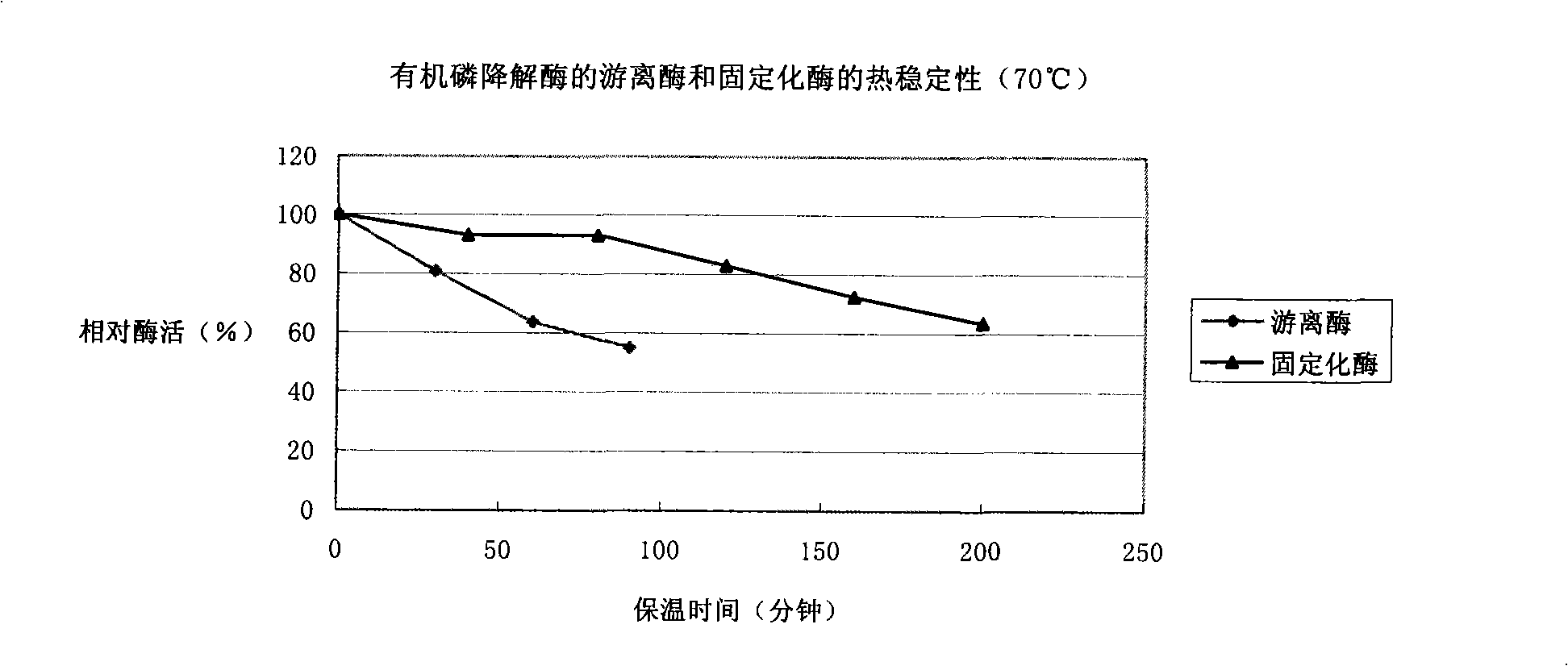

A technology of aggregates and cross-linked enzymes, applied to biochemical equipment and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc., can solve problems such as inability to recycle and reuse, and achieve The effect of easy optimization of reaction conditions, strong antitrypsin ability, and high liquid flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of immobilized cross-linked organophosphate degrading enzyme aggregates

[0028] Weigh the organophosphorus degrading enzyme and dissolve it in phosphate buffer solution to prepare an enzyme solution with a protein concentration of 0.4 mg / ml, and add porous microspheres (polystyrene type non-polar adsorption resin, model ADS-5; average pore diameter The particle size is 30nm and the particle size is greater than 100μm; performance: it does not adsorb proteins, sugars, inorganic acids, alkalis, salts, and small-molecular hydrophilic organic substances; it has high resistance to heat, acid, alkali, organic solvents, etc. Stability. Tianjin Nankai Hecheng Science and Technology Co., Ltd. formula), stirred slowly at 4°C for 3 hours; then added ammonium sulfate to a saturation of 67.5%, stirred slowly at 4°C for 5 hours; added glutaraldehyde (25%) The solution was stirred slowly at 4°C for 18 hours to a final concentration of 2.2%; the porous microspher...

Embodiment 2

[0030] Weigh lactase and dissolve it in phosphate buffered saline, prepare an enzyme solution with a protein concentration of 0.5 mg / ml, add porous microspheres (polystyrene type non-polar adsorption resin, model is ADS-5. The average pore size is 30nm , the particle size is greater than 100 μm; performance: it does not adsorb proteins, sugars, inorganic acids, alkalis, salts, and small-molecular hydrophilic organic compounds; it has high stability under conditions such as heat, acid, alkali, and organic solvents (produced by Tianjin Nankai Hecheng Technology Co., Ltd.), and stirred slowly at 4°C for 3 hours. Add ammonium sulfate to a saturation of 67.5%, and stir slowly at 4°C for 5 hours. Add glutaraldehyde (25%) solution to a final concentration of 2.2%, and stir slowly at 4°C for 18 hours. The porous microspheres were taken out by filtration, and rinsed repeatedly until the solution was clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com