Foaming washing machine

A technology for washing machines and casings, applied in the field of foaming washing machines, which can solve the problems of serious environmental pollution, waste of water sources, large amount of water and detergent, etc., and achieve the effects of reducing environmental pollution, reducing clothing wear, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

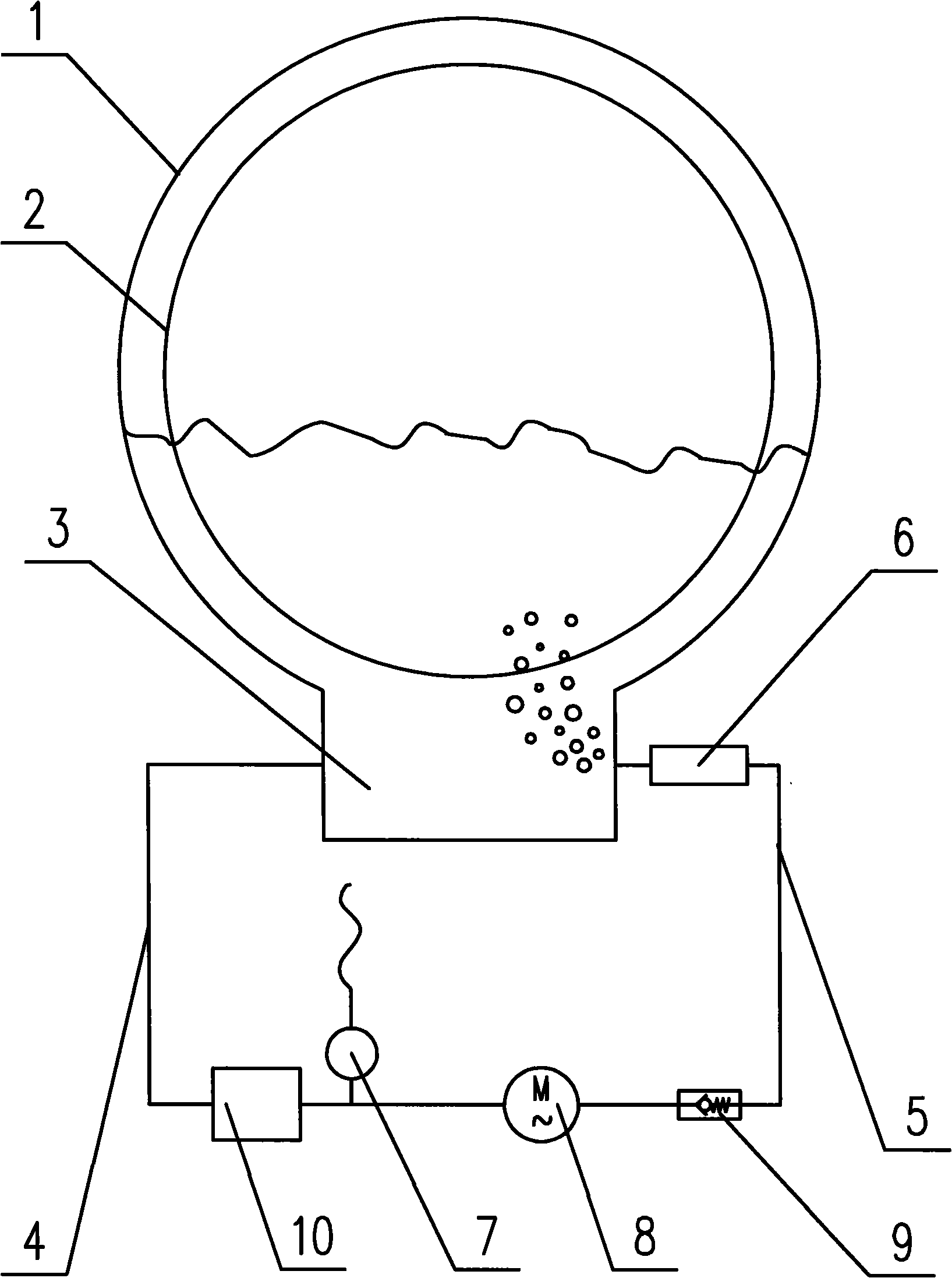

[0009] Specific implementation mode 1, figure 1 Provide a kind of concrete structure of the present invention, refer to figure 1 , a kind of foaming washing machine, it mainly comprises machine casing, and power and transmission device, control device are housed on the machine casing, has outer cylinder (1) in the machine casing, has inner drum (1) in the outer cylinder (1) 2), there is a bottom water tank (3) under the outer cylinder (1), there is a circulation pipeline on the bottom water tank (3), there is a water outlet pipe (4) on one side of the bottom water tank (3), and there is a water outlet pipe (4) on the bottom water tank (3). ) has a water inlet pipe (5) on the other side of the water inlet pipe (5), with a foam pipe (6), between the water outlet pipe (4) and the foam pipe (6), there is an air inlet pipe (7), liquid The pump (8) and the one-way valve (9) have a filtering device (10) between the water outlet pipe (4) and the air inlet pipe (7). The foaming washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com