Flame hole structure of gas burner

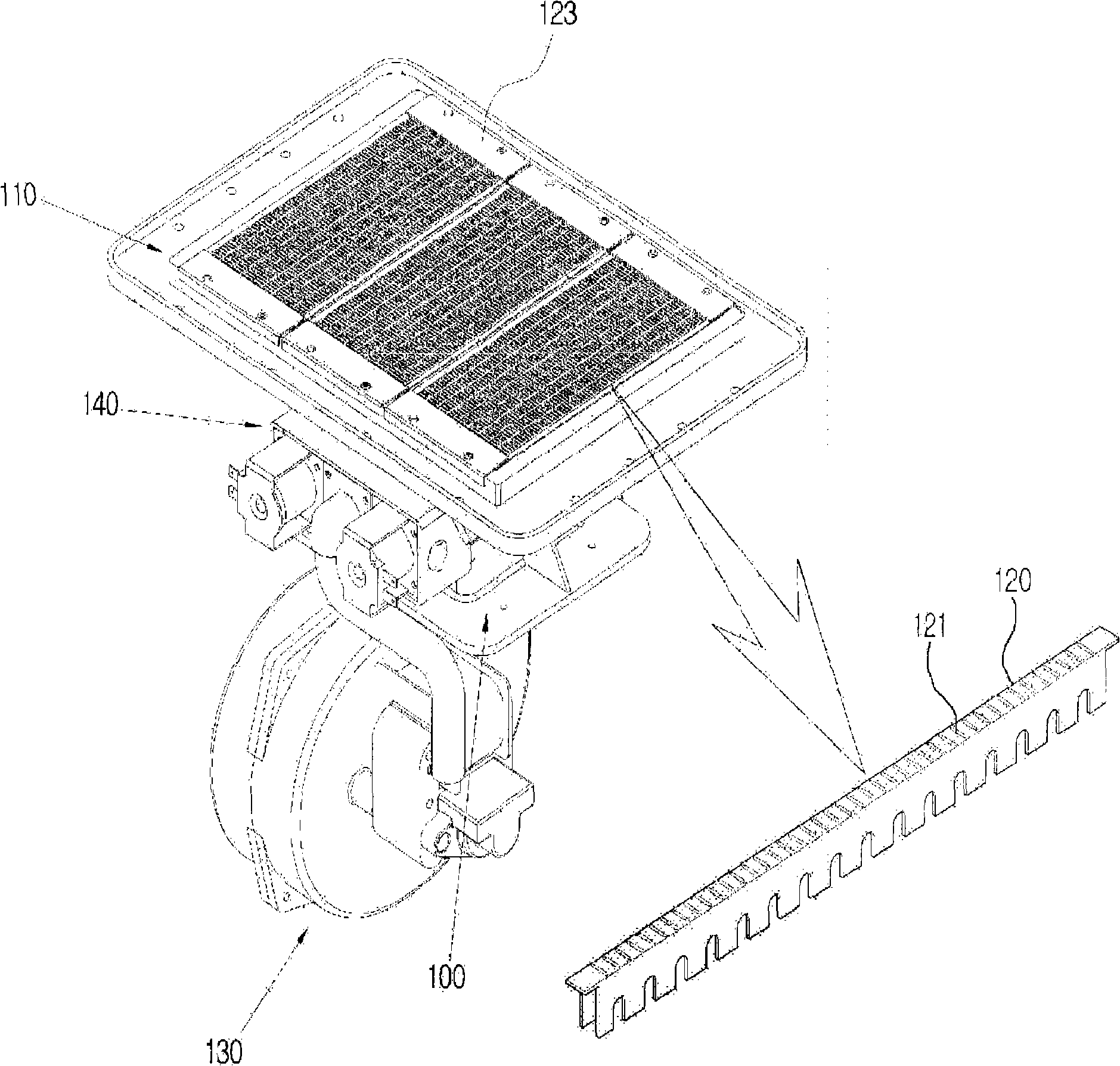

A burner and ignition burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of burning surface distortion, fire hole shape change, insufficient combustion, etc., to increase combustion load and improve characteristics , reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

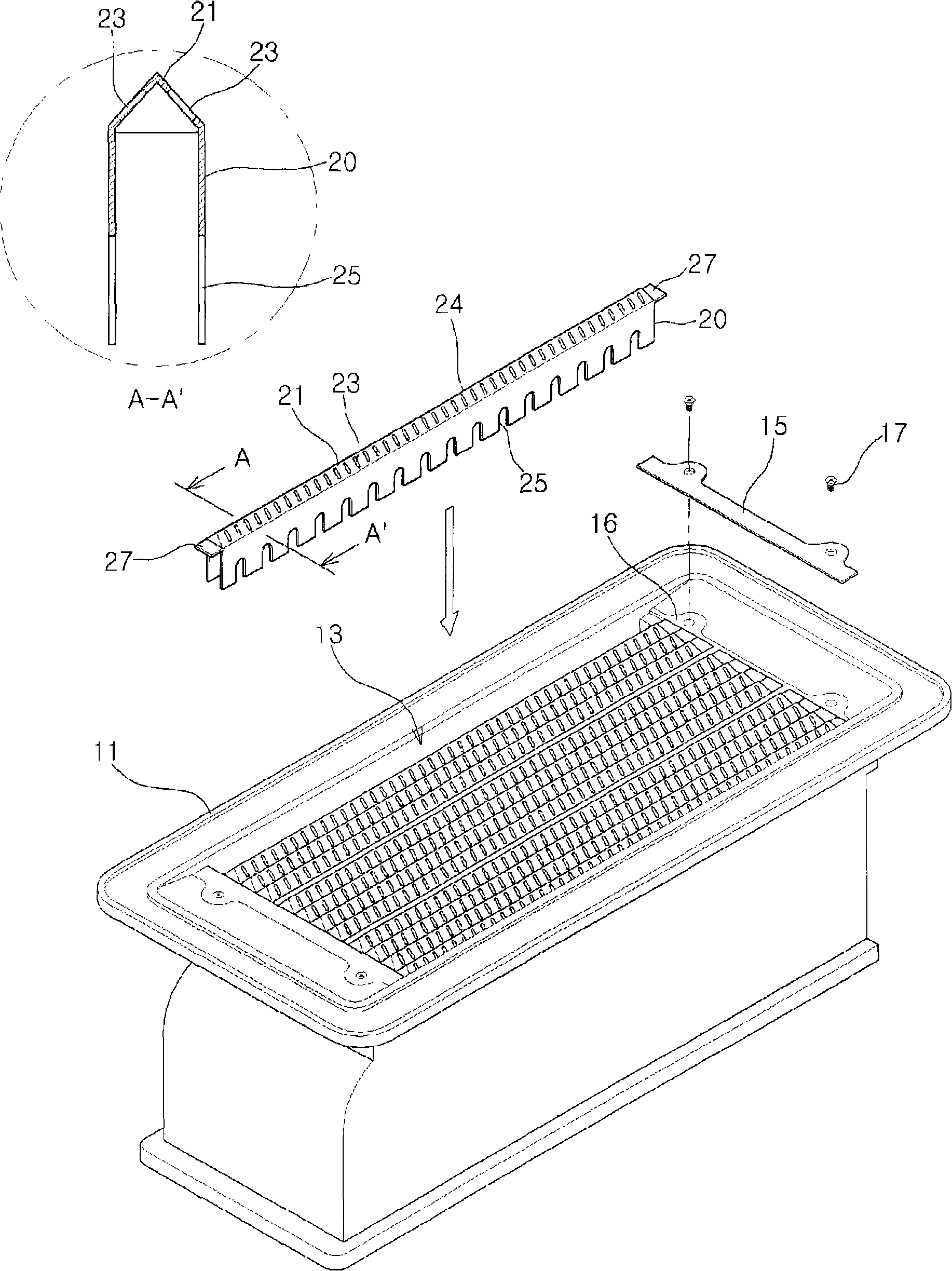

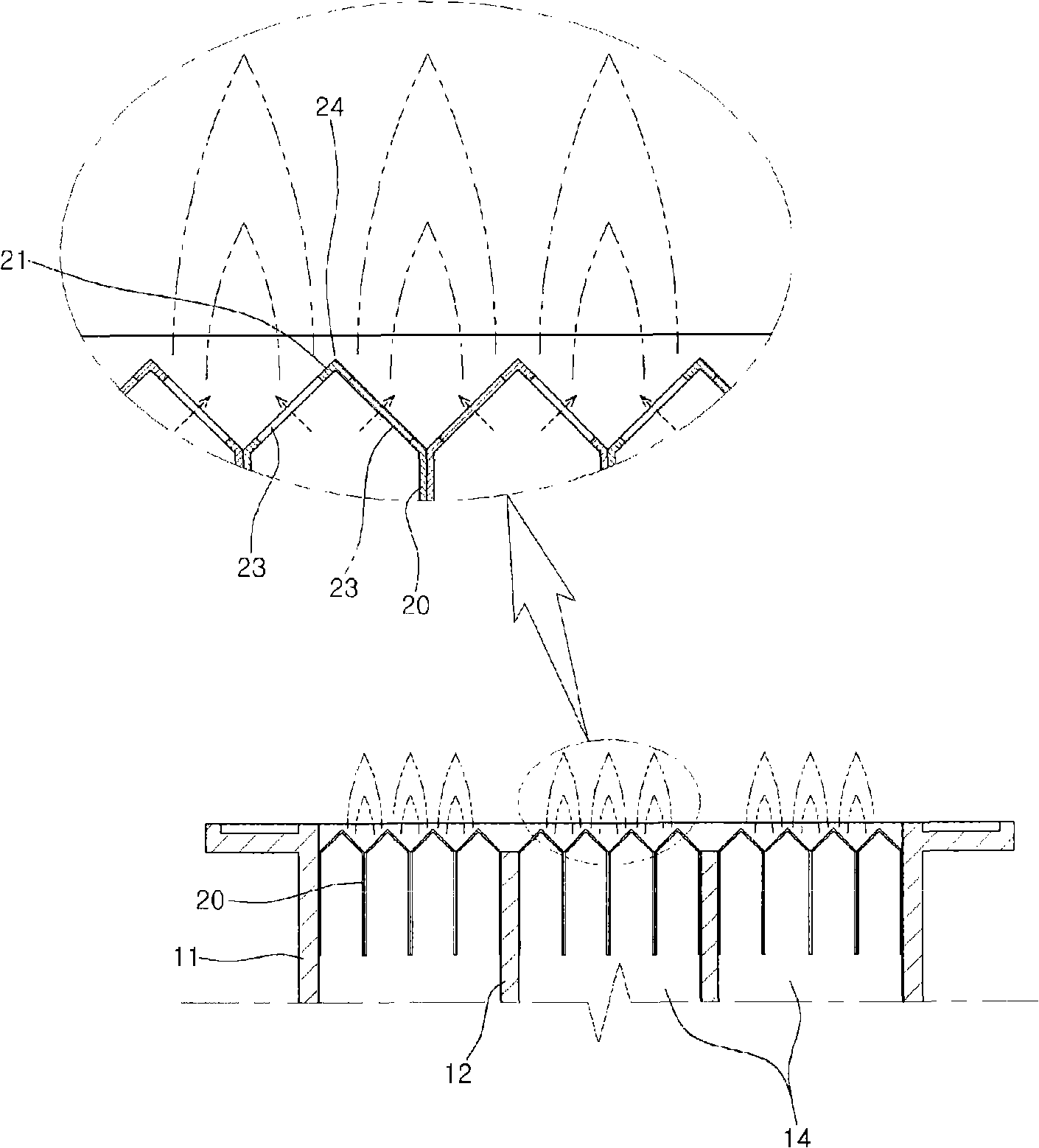

[0023] According to the present invention, there is provided a fire hole part structure of a premixed ignition burner installed on a boiler and providing heat for a boiler heat exchanger, the fire hole part structure includes the fire hole parts installed in the installation port of the burner body in parallel A plurality of fire hole sheets, each fire hole sheet is provided with a plurality of fire holes at regular intervals, wherein the upper wall of at least one fire hole sheet in the plurality of fire hole sheets is bent or bent, so as to move toward at least Extending in two directions, and the fire holes are provided through surface portions of the upper wall extending in different directions to face in different directions.

[0024] The above objects, other features and advantages of the present invention will become more apparent after reading the ensuing detailed description. Hereinafter, preferred embodiments of the present invention will be described with reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com