Quasi-hot isostatic pressing diffusion connecting mechanism and method

A technology of diffusion joining and isostatic pressing, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc. Small, high productivity, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

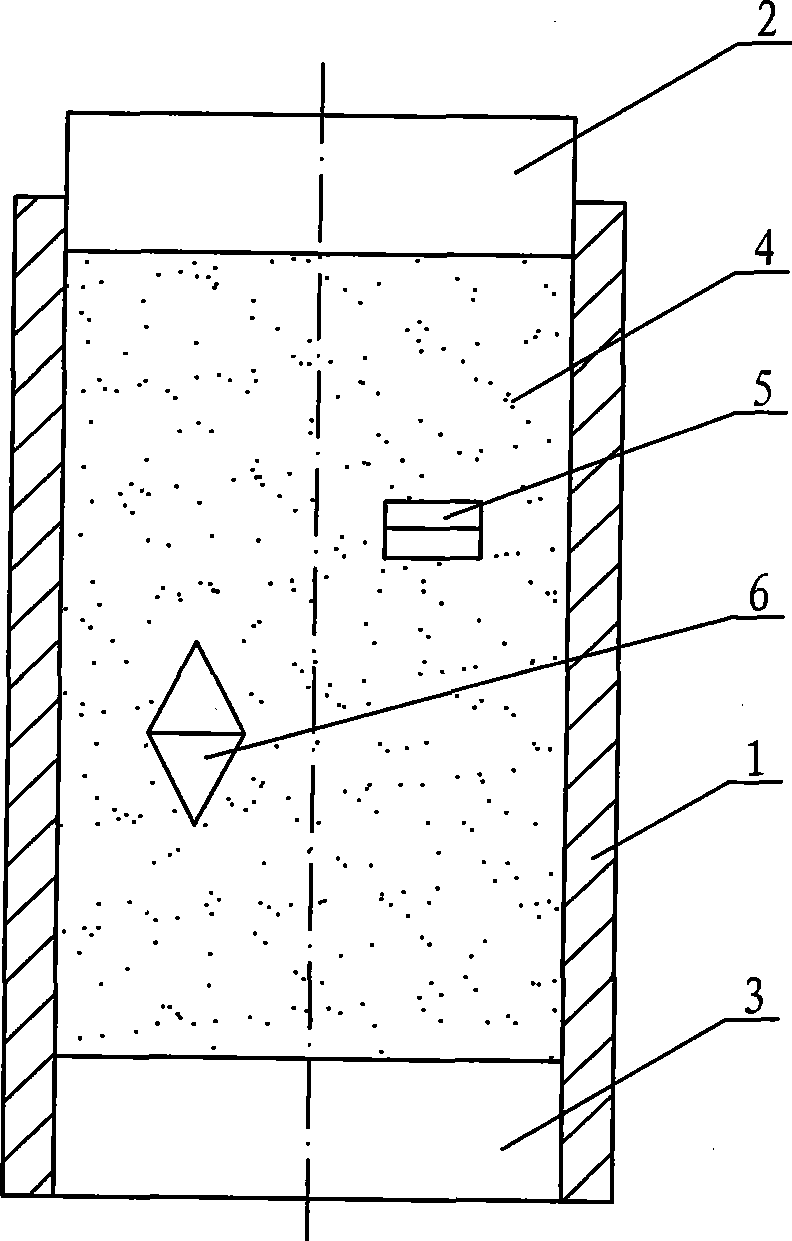

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes cylinder body 1, top slider 2, bottom slider 3 and powder 4, bottom slider 3 is arranged at the lower end of cylinder body 1, top slider 2 is arranged at the upper end of cylinder body 1 and At least half of the upper end of the top slider 2 is exposed outside the upper end surface of the cylinder 1 , and the inner cavity of the cylinder 1 is filled with powder 4 . Powder particles are used as the pressurized medium to replace the liquid or gas pressurization of the hot isostatic press, so as to assist the corresponding device on the ordinary diffusion welding machine to use the powder flow to apply equal pressure and realize the precise connection of components. The size of the cylinder body 1 is determined according to the size of the inner cavity of the diffusion welding machine; when in use, first place the bottom slider in the cylinder body 1, then put a certain a...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment will be described. The materials of the cylinder body 1 , the top slider 2 and the bottom slider 3 in this embodiment are superalloys. The high-temperature alloy can guarantee the strength of the device during the connection process; under the conditions of the connection pressure and temperature required by the components to be connected, the material of the cylinder 1, the top slider 2 and the bottom slider 3 can be selected from high-strength graphite to save costs.

specific Embodiment approach 3

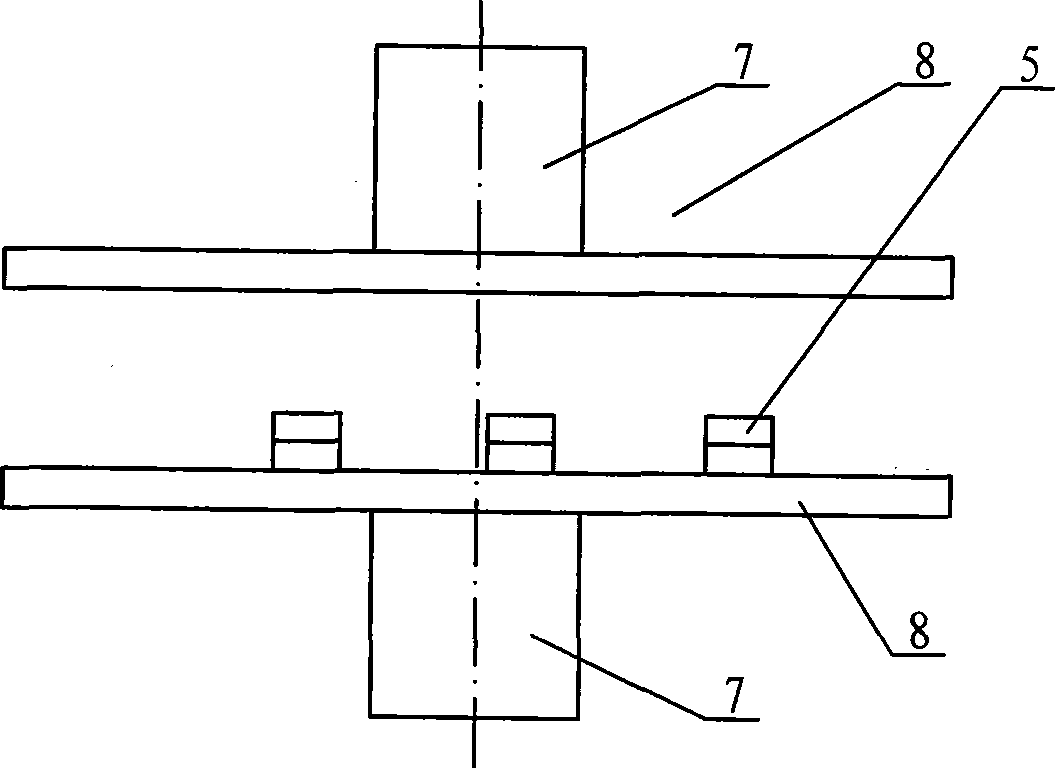

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the quasi-hot isostatic pressure diffusion connection method of this embodiment is realized through the following steps: 1. Surface finishing and ultrasonic cleaning of the two components to be connected; 2. The two components to be connected in step 1 The surfaces of the components are relatively superimposed, and the side surfaces after the butt joint are covered with 50-100 μm metal foil (this is to prevent the powder 4 from penetrating into the surface to be connected under pressure), and the metal foil is wound with a metal wire to fix it. Embed in the powder 4 in the inner cavity of the cylinder body 1; 3. Put the quasi-hot isostatic pressure diffusion connection device equipped with the components to be connected into the furnace of the diffusion welding machine, and the pressure head on the welding machine directly acts on the top slider 2 First, the connection temperature is 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap