Rope and traction pulley wheel for elevator apparatus and elevator apparatus

A technology of traction pulleys and ropes, which is applied in the direction of elevators, transmission elements or pulley ropes or cables, textile cables, etc. in buildings, and can solve the problems of bearing core wire contact, reducing the strength and wear of tensile components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

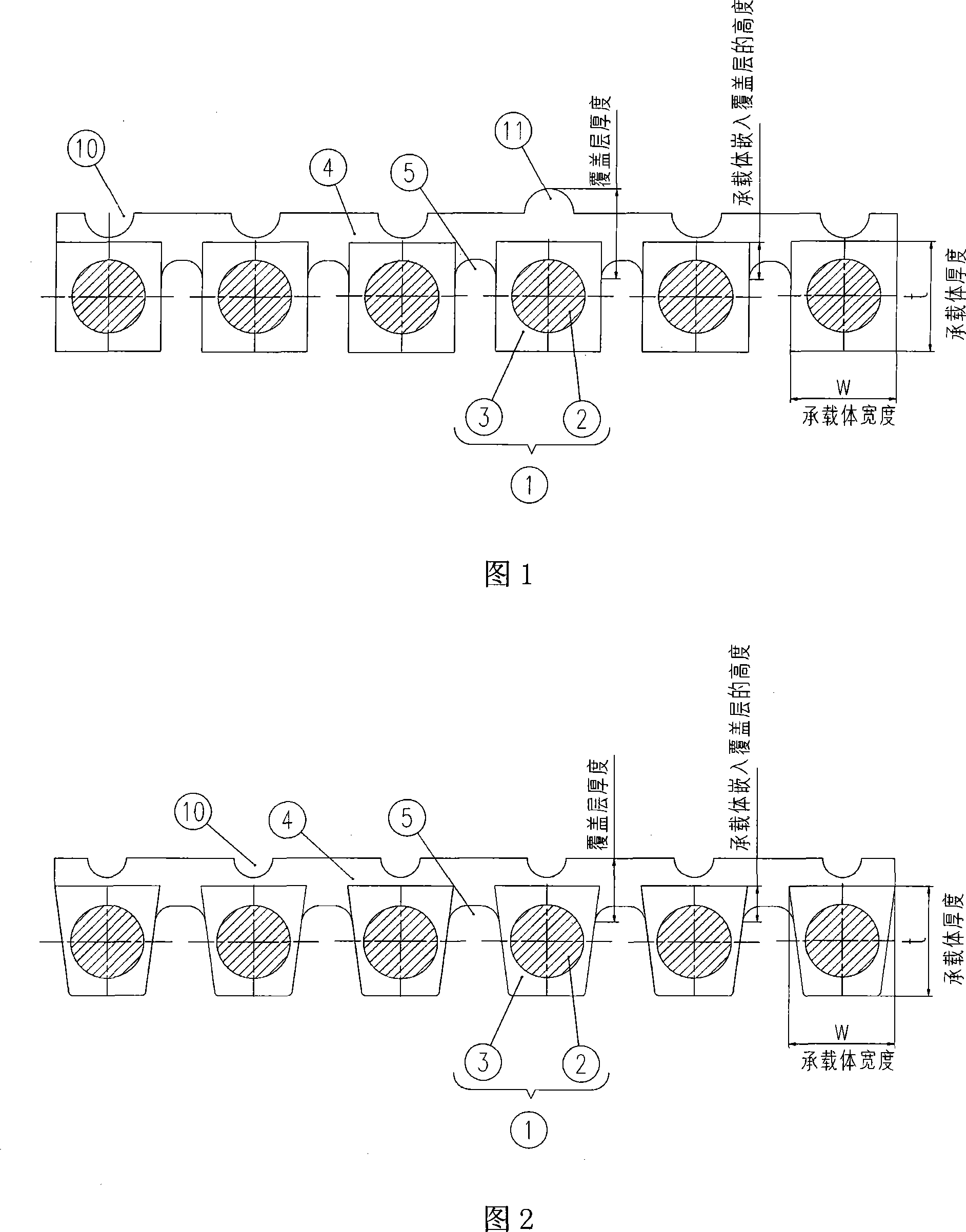

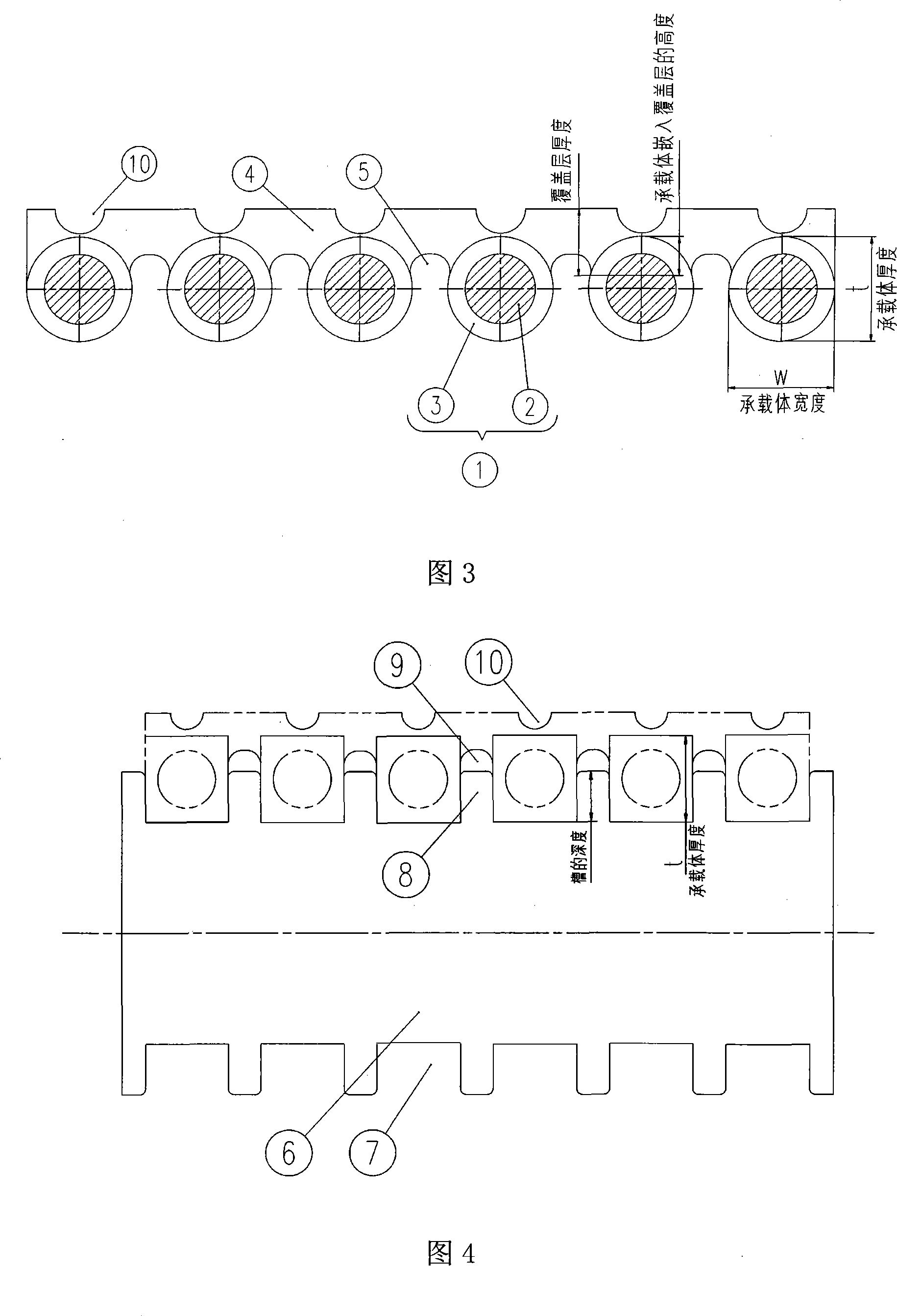

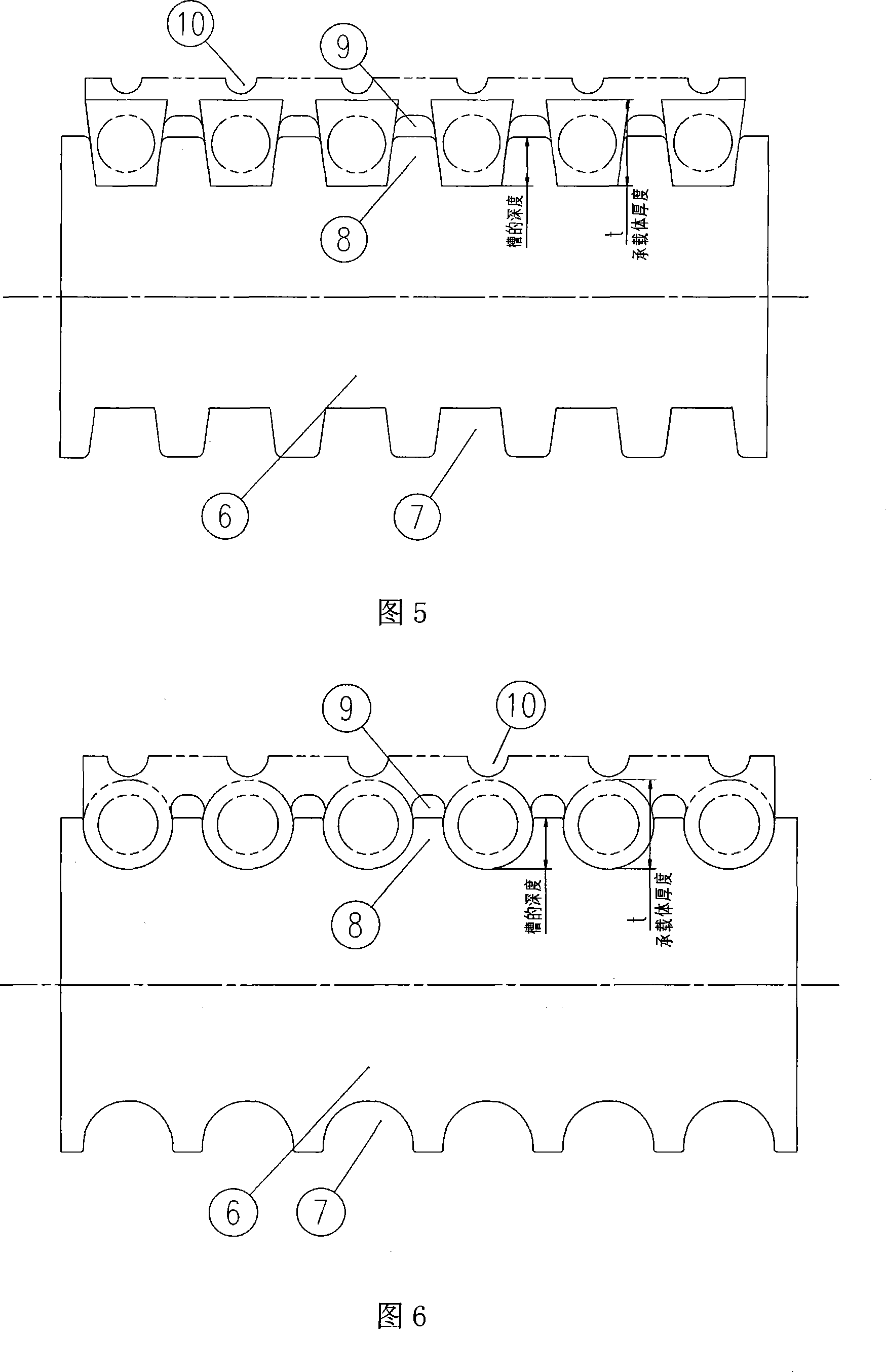

[0023] Such as figure 1 As shown, in the first structure of the rope for the elevator device, the rope is composed of six carriers 1 and one covering layer 4 . The carrier 1 is composed of a carrier core 2 and an enclosure 3 . The carriers 1 are arranged at a certain interval, and the covering layer 4 and the carriers 1 are connected together. The inclusion 3 and the covering layer are made of non-metallic materials. The carrier 1 has dimensions of a width w between its left and right and a thickness t measured in the bending direction between its top and bottom, wherein the ratio of the thickness t to the width w≧1. Each of the carriers 1 is partially embedded in the covering layer 4 . Since the thickness of the covering layer 4 is smaller than that of the supporting body 1 , the covering layer 4 can be designed to enable the relative displacement between the supporting bodies 1 in the longitudinal direction of the supporting body 1 . Since each of the plurality of beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com