Heating apparatus and glass manufacturing method

A heating device and glass manufacturing technology, applied in glass manufacturing equipment, glass pressing, manufacturing tools, etc., can solve the problems of glass product optical property degradation, streaks, uneven temperature distribution of molten glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation methods, The method, steps, structure, features and effects thereof are described in detail below.

[0063] Hereinafter, an embodiment structure of the present invention will be described with reference to the drawings. In addition, in the description of each embodiment structure other than the first embodiment structure, the same reference numerals are used for the same parts as the first embodiment structure, and related descriptions are omitted.

[0064]

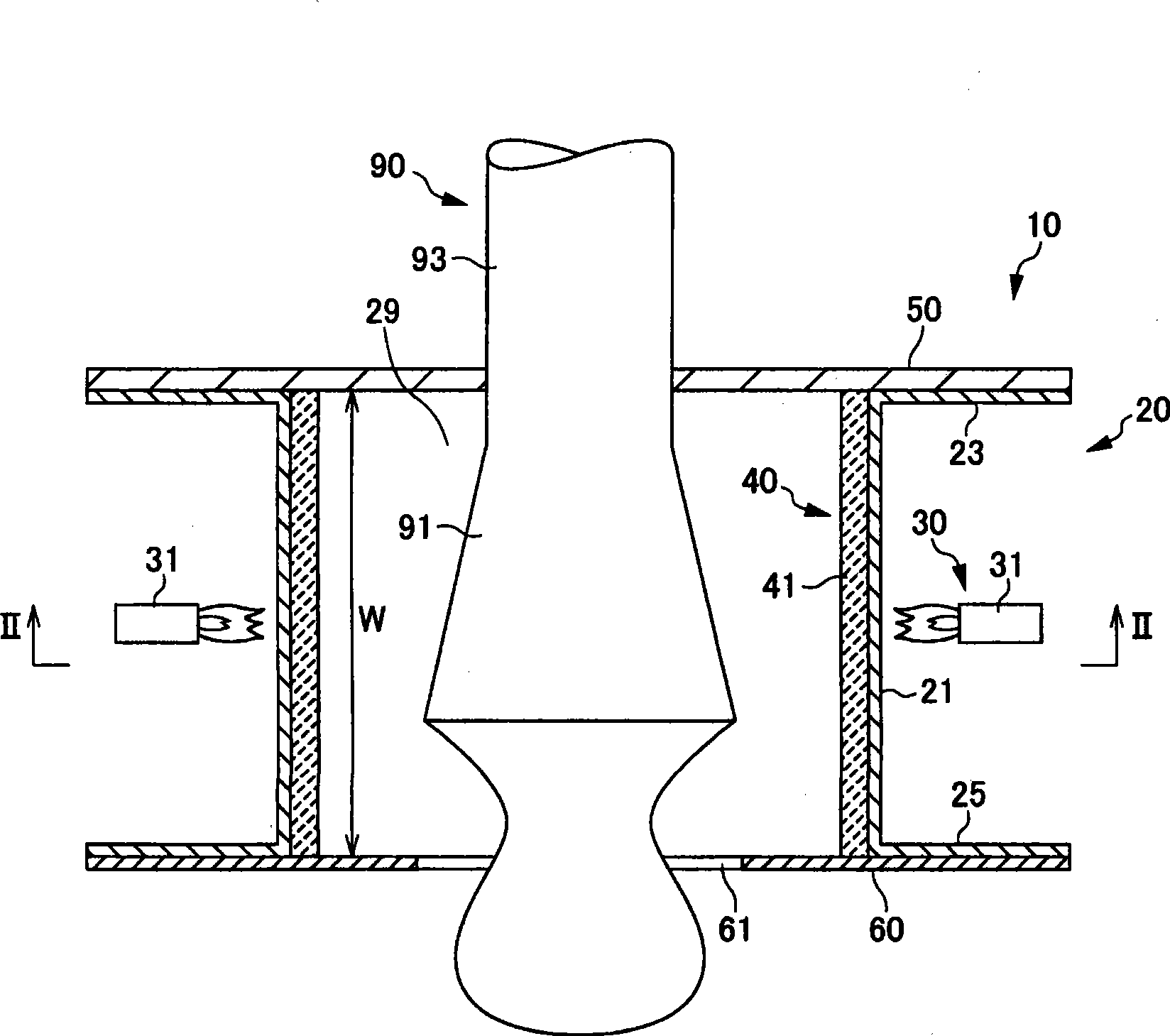

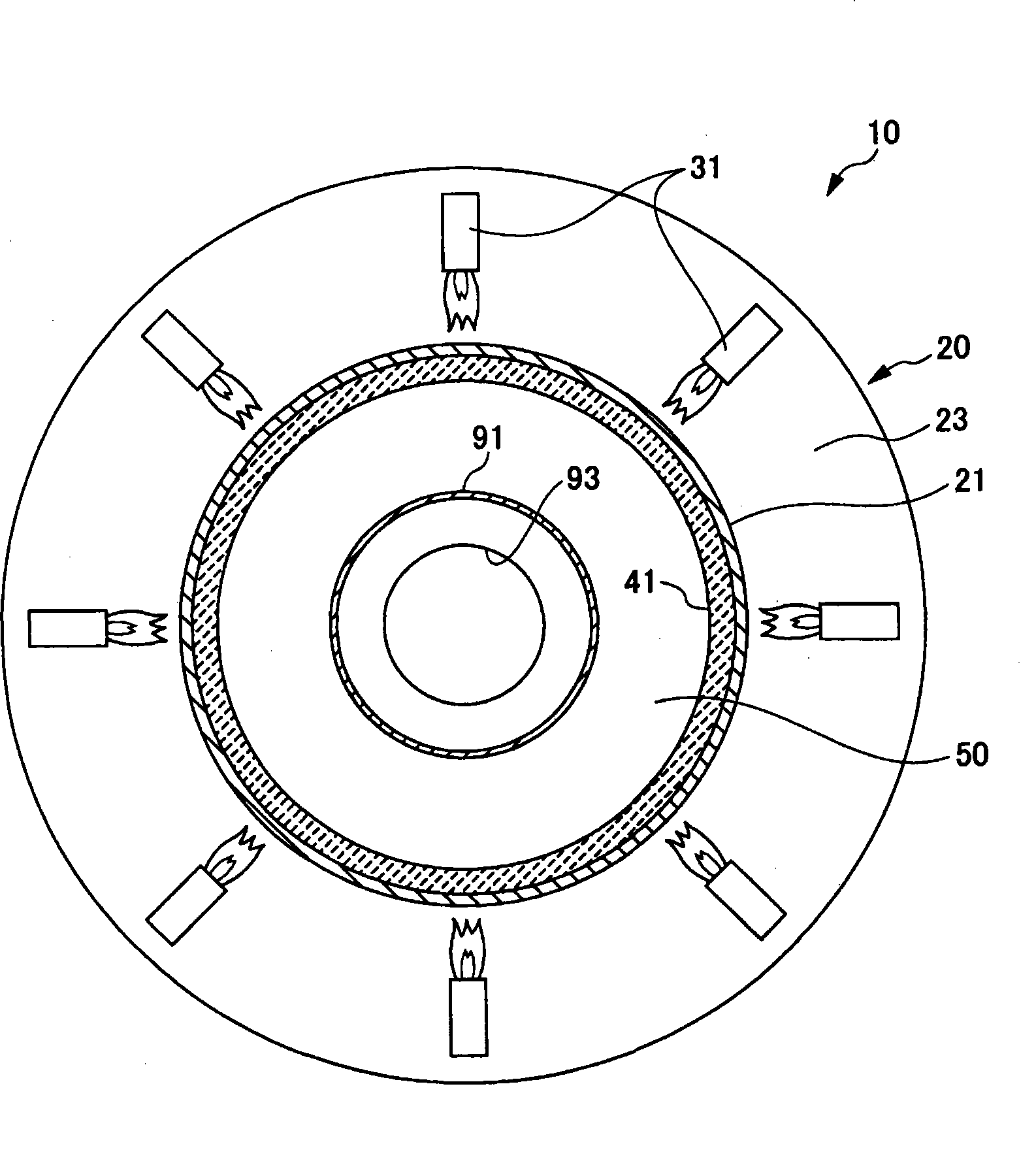

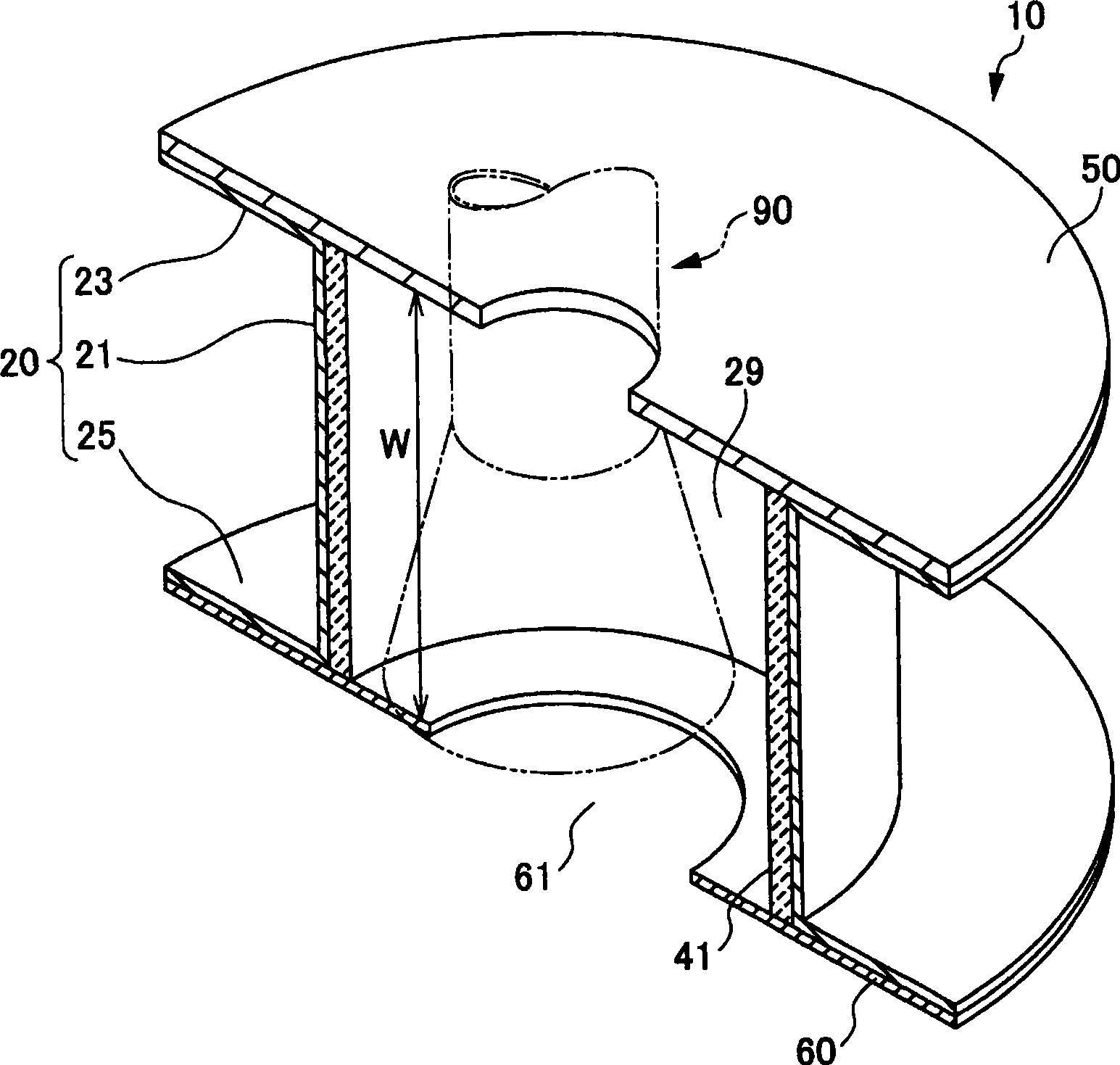

[0065] figure 1 It is a schematic configuration diagram of the heating device 10 in the first embodiment of the present invention. in addition, figure 2 yes figure 1 A sectional view on the line II-II of image 3 yes figure 1 partial perspective view.

[0066] The heating device 10 includes a frame body 20 , a heating unit 30 as a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com