Blue fluorescent powder and preparation thereof

A blue phosphor, general technology, applied in the field of materials, can solve problems such as thermal aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

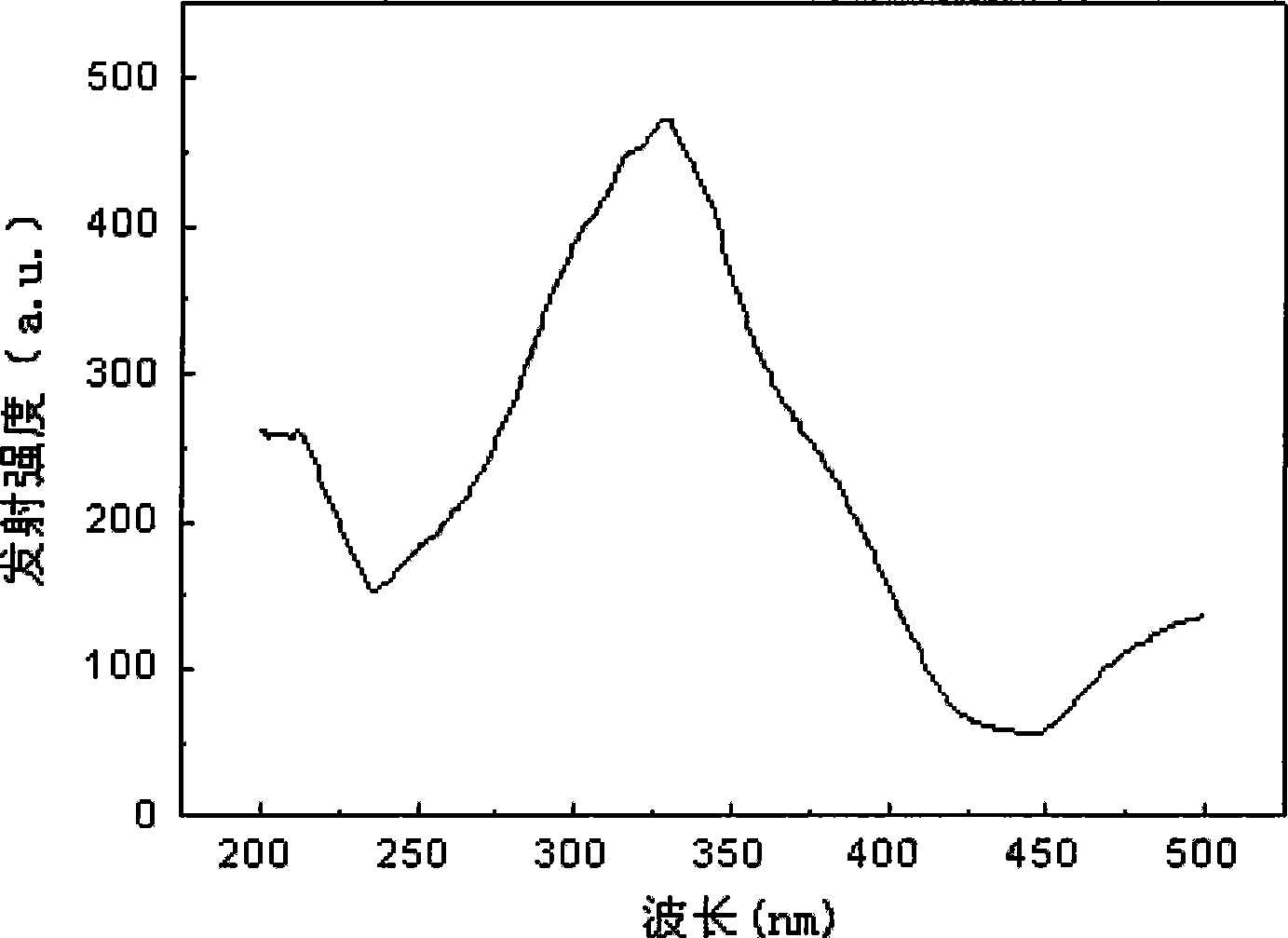

[0032] To prepare the general formula Mg 1-x-y Sr y al 2 o 4 :Eu x The blue phosphor 10g represented is an example, where x is the number of moles of europium atoms, y is the number of moles of strontium atoms, x is 0.02, and y is 0.10. The raw materials used and their preparation methods are as follows:

[0033] 1. Raw material pretreatment

[0034] Strontium carbonate and europium oxide were pre-fired in a high-temperature furnace at 850°C for 2 hours to remove moisture and impurities.

[0035] 2. Ingredients

[0036] According to the general formula Mg 0.88 Sr 0.10 al 2 o 4 :Eu 0.02 1.0392g of strontium carbonate, 6.0173g of basic magnesium carbonate, 10.9824g of aluminum hydroxide, 0.2478g of europium oxide were weighed, and the flux was 0.5g of boric acid, and ground in a mortar for 20 minutes to prepare a raw material mixture.

[0037] 3. Sintering

[0038] The raw material mixture was put into a corundum crucible, placed in a high-temperature furnace, and si...

Embodiment 2

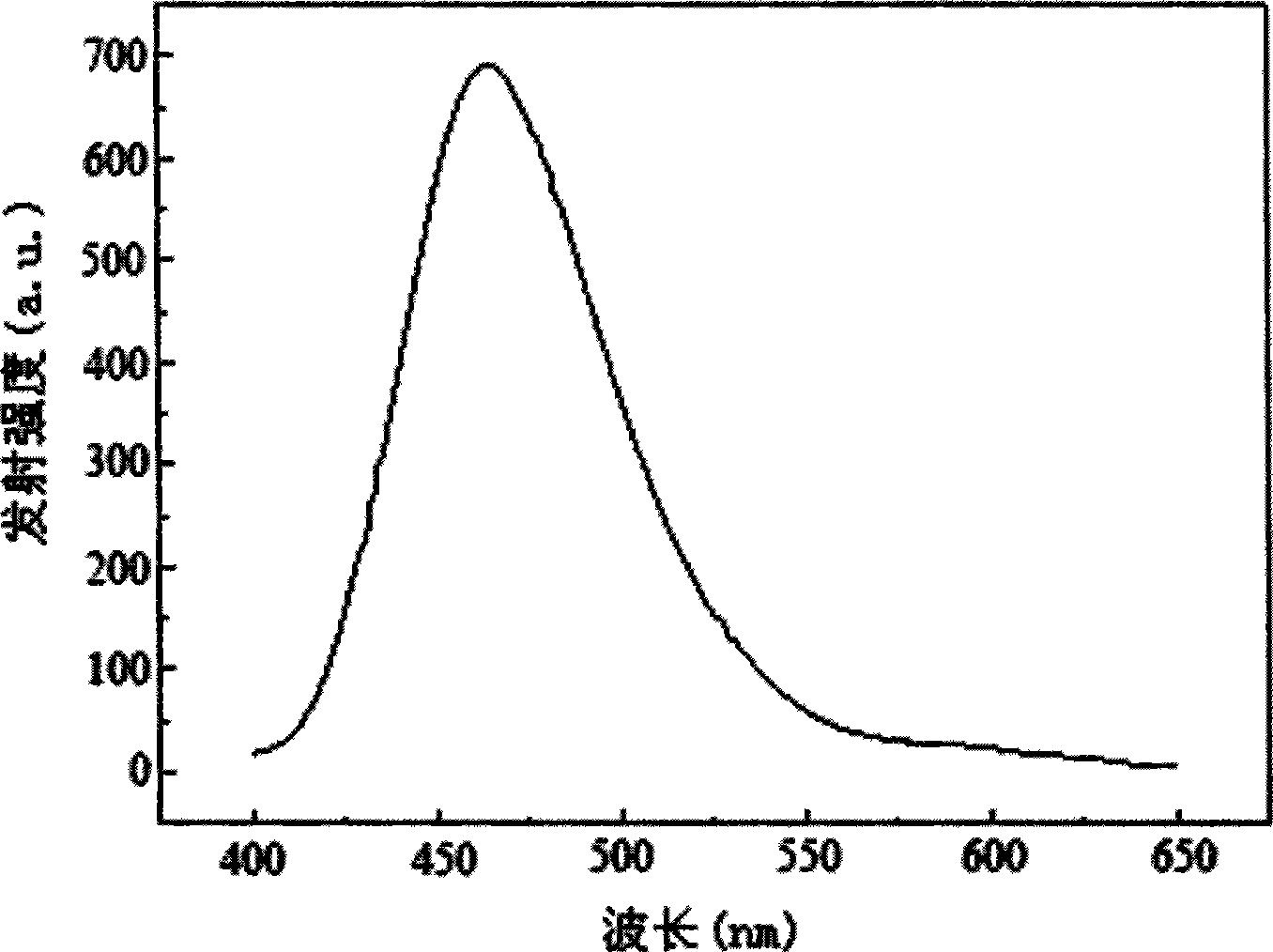

[0044] To prepare the general formula Mg 1-x-y Sr y al 2 o 4 :Eu x The blue phosphor 10g represented is an example, where x is the number of moles of europium atoms, y is the number of moles of strontium atoms, x is 0.02, and y is 0.10. The raw materials used and their preparation methods are as follows:

[0045] In batching step 2, according to the general formula Mg 0.88 Sr 0.10 al 2 o 4 :Eu 0.02 Take by weighing strontium carbonate, basic magnesium carbonate, aluminum hydroxide, europium oxide respectively, consumption is identical with embodiment 1, flux is 0.1g boric acid, other steps of this step are identical with embodiment 1, are prepared into raw material mixture; In step 3, the raw material mixture is put into a corundum crucible, placed in a high-temperature furnace, and sintered in activated carbon at 1300° C. for 7 hours. After the reaction is completed, it is naturally cooled to room temperature. Other steps are the same as in Example 1 to prepare blue ...

Embodiment 3

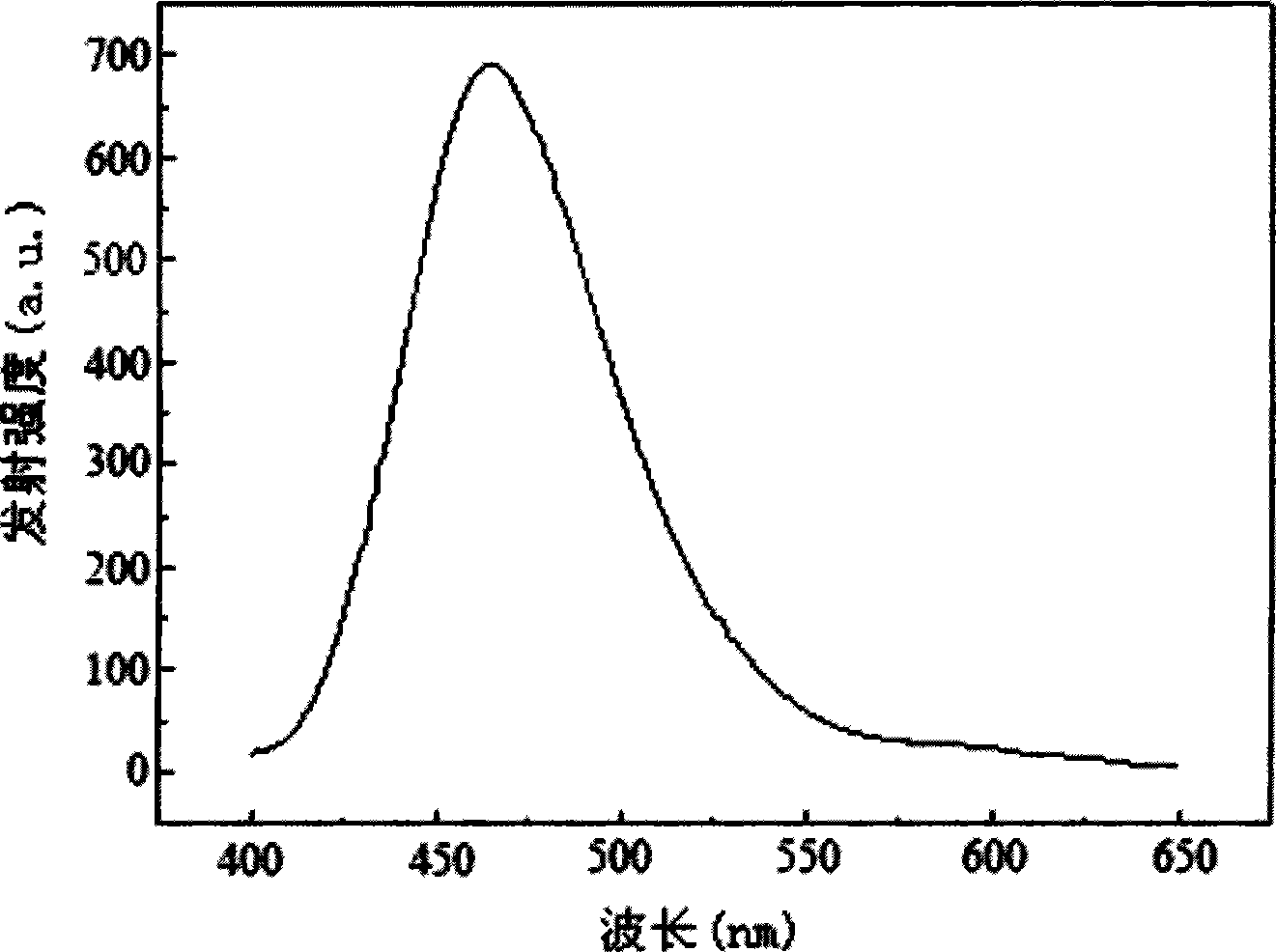

[0047] To prepare the general formula Mg 1-x-y Sr y al 2 o 4 :Eu xThe blue phosphor 10g represented is an example, where x is the number of moles of europium atoms, y is the number of moles of strontium atoms, x is 0.02, and y is 0.10. The raw materials used and their preparation methods are as follows:

[0048] In batching step 2, according to the general formula Mg 0.88 Sr 0.10 al 2 o 4 :Eu 0.02 Take by weighing strontium carbonate, basic magnesium carbonate, aluminum hydroxide, europium oxide respectively, consumption is identical with embodiment 1, flux is 0.7g boric acid, other steps of this step are identical with embodiment 1, are prepared into raw material mixture; In step 3, the raw material mixture is put into a corundum crucible, placed in a high-temperature furnace, and sintered in activated carbon at 1500° C. for 3 hours. After the reaction is completed, it is naturally cooled to room temperature. Other steps are the same as in Example 1 to prepare blue p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap