Electrolytic apparatus for aluminum base plate for printing

An electrolytic device, aluminum-based technology, applied in printing, printing surface preparation, anodic oxidation, etc., can solve the problems affecting the uniformity of electrolytic sand, affecting the efficiency of electrolytic composite sand, and the difference in reaction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

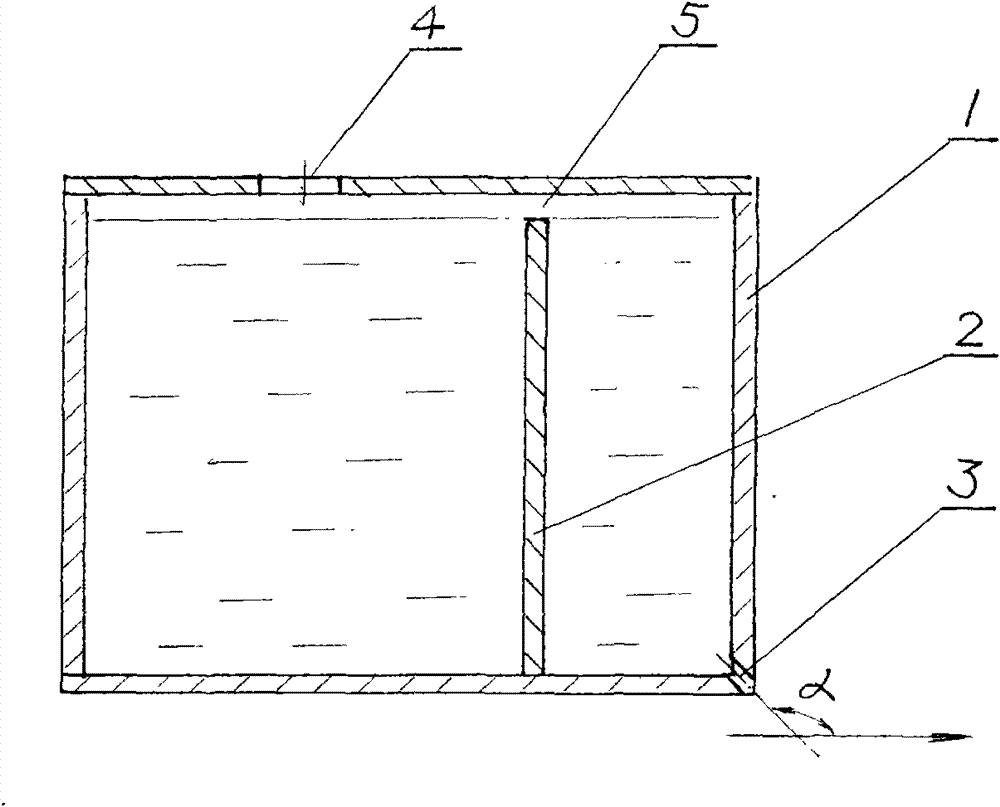

[0008] Referring to the accompanying drawings, the liquid supply box body 1 is a cuboid, with an inlet 4 connected to the liquid supply pipe in the middle of the top, and a strip-shaped liquid outlet 3 on the bottom side, which is as long as the box body. The longitudinal central plane of the liquid outlet is inclined to the horizontal plane and forms an angle α=135° with the advancing direction of the aluminum substrate (pointed by the arrow in the figure). The sides are all sealed and combined with the inner wall of the box, and there is a gap 5 on the upper side. The above-mentioned inlet 4 and liquid outlet 3 are respectively located on both sides of the inner partition, and the cross-sectional area of the liquid outlet 3 (that is, the cross-sectional area of the liquid outlet) is less than The cross-sectional area of the inlet 4 and the cross-sectional area of the inner partition gap 5. The above-mentioned included angle α may also be selected as 120°, 130°, 140° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com