Non-phosphate scouring agent and preparation thereof

A scouring agent and isomerization technology, applied in the field of fabric pretreatment additives, to achieve the effect of excellent emulsification and dispersion, high efficiency, and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

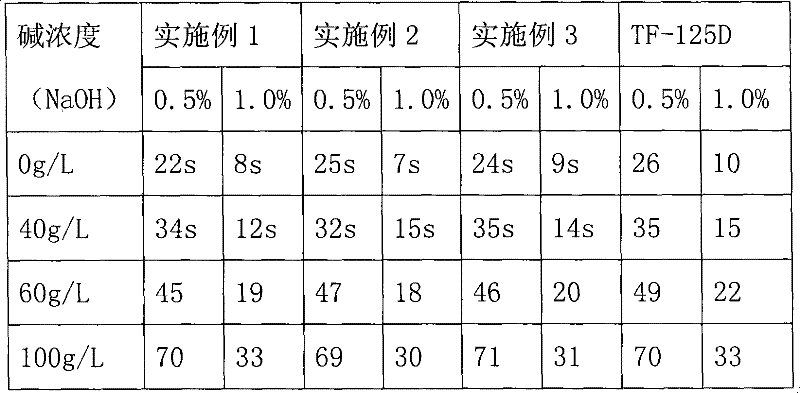

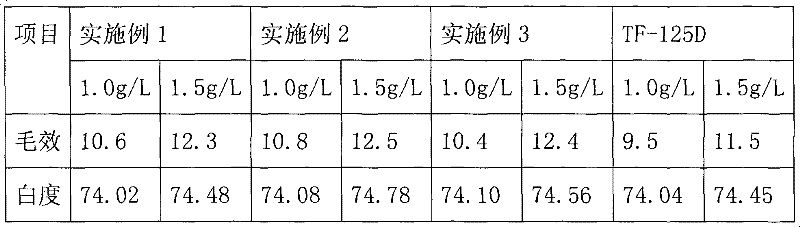

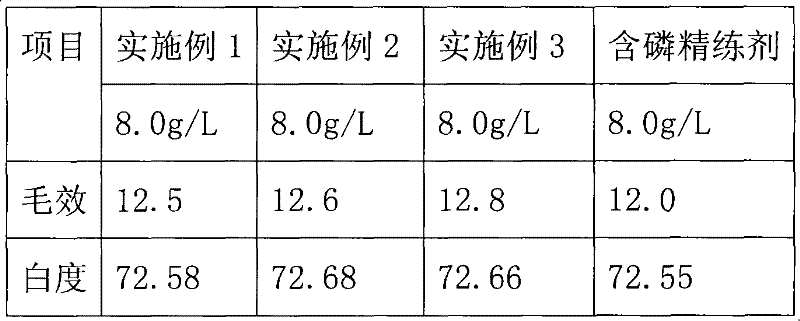

Examples

Embodiment 1

[0013] The components and weight percentages of the phosphorus-free scouring agent are as follows:

[0014] Isomerized C8 alcohol ether (6EO) carboxylate 15%, C8-10 alkyl glycoside 15%, isomerized C8-10 alcohol polyoxyethylene ether (3EO) 10%, deionized water 60%.

Embodiment 2

[0016] The components and weight percentages of the phosphorus-free scouring agent are as follows:

[0017] Isomerized C10 alcohol ether (3EO) carboxylate 18%, C8-10 alkyl glycoside 14%, isomerized C10-12 alcohol polyoxyethylene ether (5EO) 8%, deionized water 60%.

Embodiment 3

[0019] The components and weight percentages of the phosphorus-free scouring agent are as follows:

[0020] Isomerized C13 alcohol ether (5EO) carboxylate 25%, C10-12 alkyl glycoside 10%, isomerized C13-15 alcohol polyoxyethylene ether (6EO) 5%, deionized water 60%.

[0021] The isomeric C8 alcohol ether (6EO) in the above example 1 specifically refers to the product obtained by adding isomeric C8 alcohols to 6 EO (ethylene oxide), and other similar expressions also refer to this meaning.

[0022] The preparation method of the phosphorus-free scouring agent of above-mentioned three embodiments is:

[0023] Put the isomeric alcohol ether carboxylate, alkyl glucoside, isomeric alcohol polyoxyethylene ether and deionized water into the reaction kettle according to the formula ratio, and stir and mix for 20-40 minutes at normal pressure and 40-50°C , cooling, filtering and packaging to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com