Supporting roller shift apparatus of closed box body oil pump

A technology of closed box and shifting device, which is applied in the direction of transmission device, friction transmission device, mining fluid, etc., and can solve problems such as difficult workover operations and difficult equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

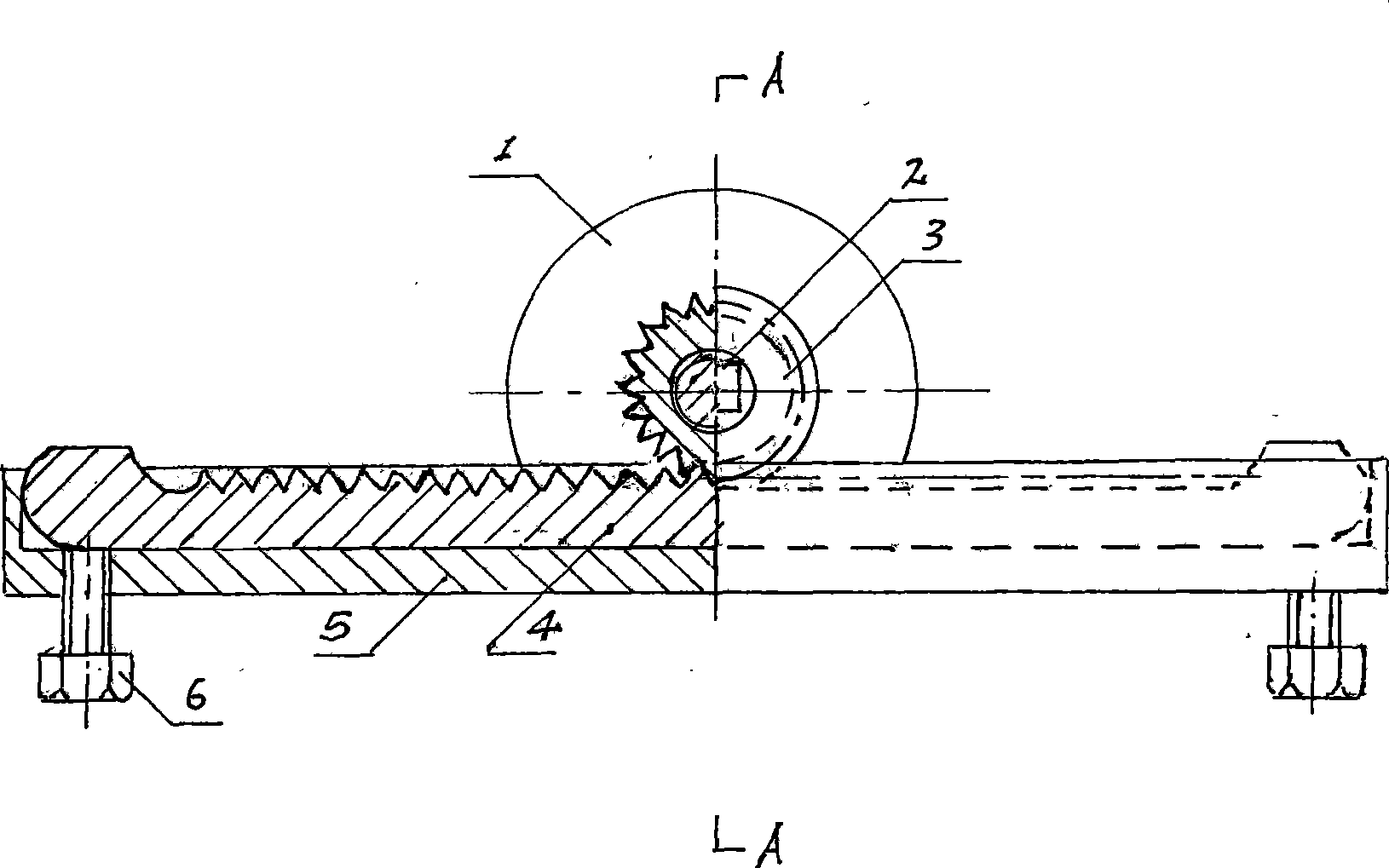

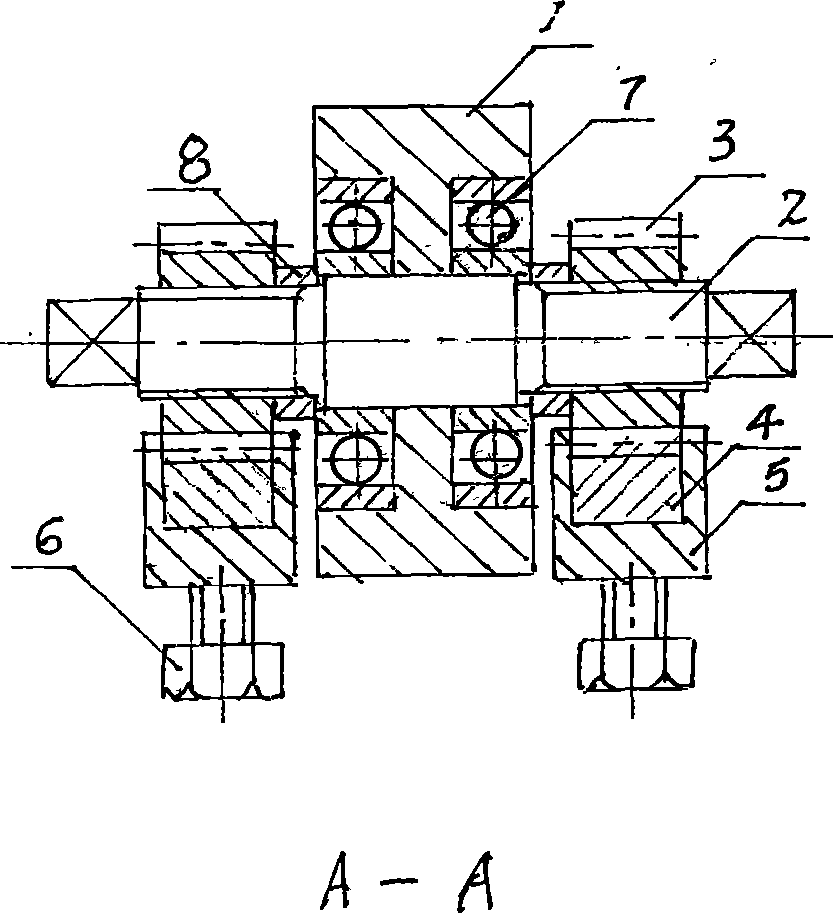

[0008] see below figure 1 and figure 2 Describe in detail.

[0009] exist figure 1 and figure 2 Among them, the supporting wheel shifting device of the closed box pumping unit is composed of a supporting wheel 1, a supporting wheel shaft 2, a gear 3, a rack 4, a bar-shaped groove body 5, a shifting bolt 6, a bearing 7 and a washer 8, The supporting wheel (1) is a circular wheel, and the center of the wheel is provided with a through hole, and bearings (7) are fixed on both sides of the through hole. The two ends of the supporting wheel shaft (2) are squares, and the inner length of the square body is provided with external threads, and the length in the middle of the supporting wheel shaft (2) is a protruding circle. Gear (3) is a circular gear, and a through hole is established in the center, and the through hole is provided with internal thread. The tooth bar (4) is elongated, and the tooth bar (4) is provided with teeth, and the two ends are not provided with teeth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com