Method for improving quality of solid-state dual-type fermented white wine

A double-type and liquor technology, which is applied in the field of liquor brewing and solid-state double-type fermentation to produce liquor, can solve problems affecting the quality of solid-state double-type liquor, and achieve the effects of satisfying drinking habits, increasing the rate of high-quality wine, and increasing the rate of high-quality wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the large slag is not taken after the fermentation is completed, and it is directly mixed into the strong-flavor mash below the pit level for fermentation. The fermentation and aroma production time is 90 days, and the fermentation production cycle is relatively short.

[0025] (1) In the same pit, the fermented grains above the pit opening level are fermented for 30 days using the fragrant liquor brewing process, and the fermented grains below the pit opening level are fermented for 30 days using the aromatic liquor brewing process;

[0026] (2) After the fermentation of the fragrant large slag mash, do not take the wine, and directly mix the large slag into the luscious mash below the pit surface;

[0027] (3) Add 30 kg / Zeng Fanshaqu, 20 kg / Zeng yellow water and 50 kg / Zeng second wine to the mixed grains, and then enter the cellar according to the traditional strong-flavor fermentation process;

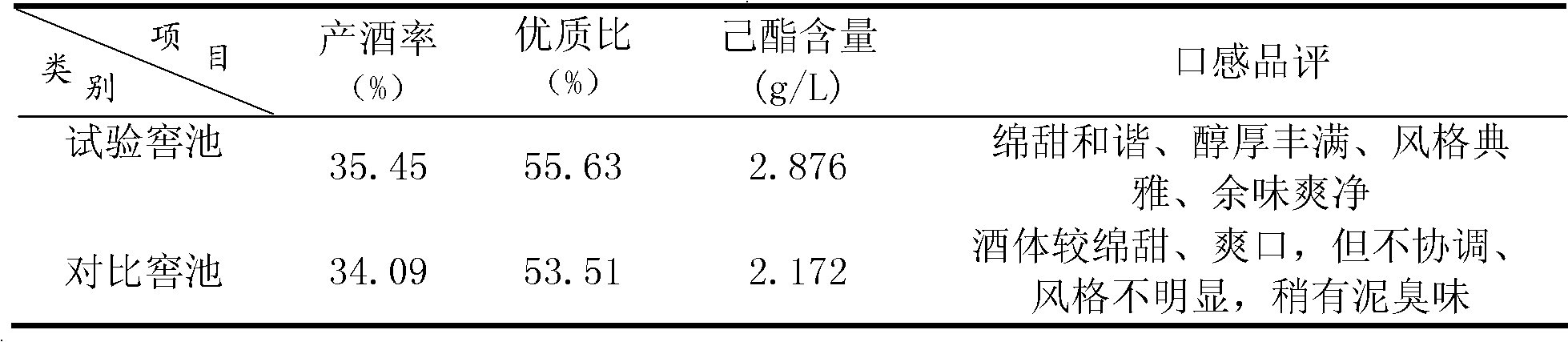

[0028] (4) According to the traditional strong-flavor ferment...

Embodiment 2

[0033] In this embodiment, the large slag is not taken after the fermentation is completed, and it is directly mixed into the strong-flavor mash below the pit level for fermentation. The fermentation and aroma production time is 120 days, and the fermentation production cycle is relatively short.

[0034] (1) In the same pit, the fermented grains above the pit opening level are fermented for 30 days using the fragrant liquor brewing process, and the fermented grains below the pit opening level are fermented for 30 days using the aromatic liquor brewing process;

[0035] (2) After the fermentation of the fragrant large slag mash, do not take the wine, and directly mix the large slag into the luscious mash below the pit surface;

[0036] (3) Add 40 kg / Zeng Fanshaqu, 30 kg / Zeng yellow water and 50 kg / Zeng second wine to the mixed grains, and then enter the cellar according to the traditional strong-flavor fermentation process;

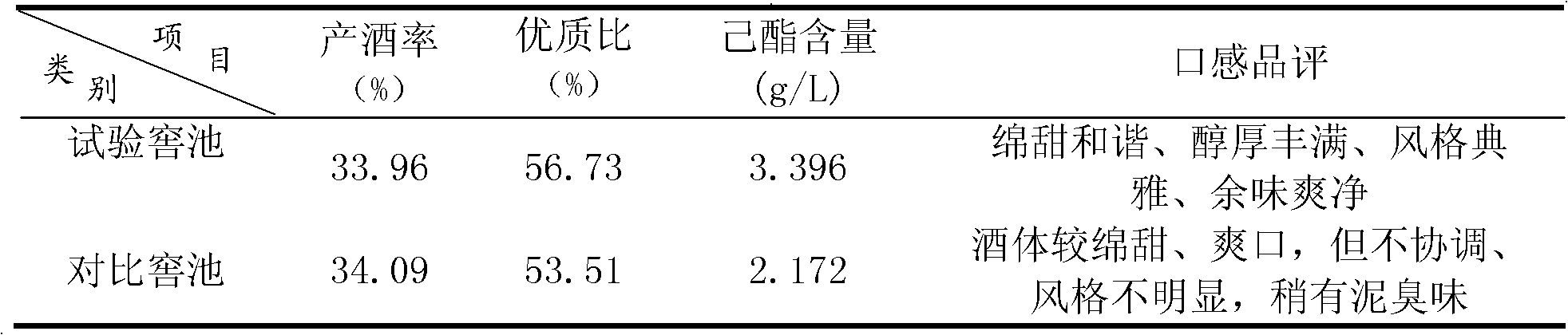

[0037] (4) After sealing the cellar according to the traditi...

Embodiment 3

[0042] In this embodiment, the wine is distilled after the fermentation of the big residue, and then the second residue fermentation is carried out. The mash after the second residue fermentation is not taken from the wine, and it is directly mixed into the strong-flavor mash below the pit surface for fermentation. The fermentation and aroma production time is 110 days, and the fermentation and aroma production cycle is relatively short.

[0043] (1) In the same pit, the fermented grains above the pit opening level are fermented for 30 days using the fragrant liquor brewing process, and the fermented grains below the pit opening level are fermented for 30 days using the aromatic liquor brewing process;

[0044] (2) After the fermentation of the fragrant large slag mash is finished, the wine is taken, and then low-temperature daqu powder is added for the second slag fermentation for 20 days;

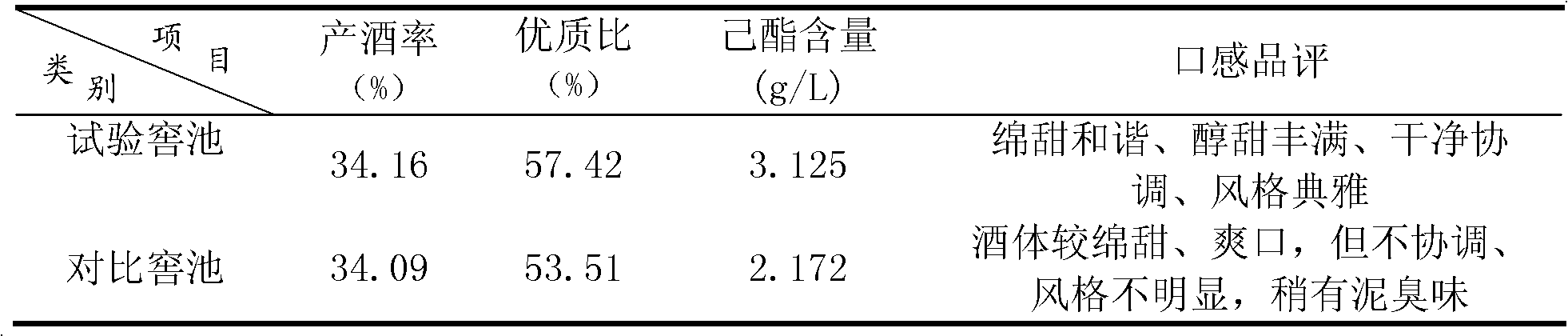

[0045] (3) After the fermentation of the fragrant two residues, no wine is taken. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com