Method for carrying out segmented wine picking by utilizing conductivity of raw wine

A segmented wine picking and conductivity technology, which is applied in the preparation of alcoholic beverages, material resistance, etc., can solve the problems that the quality stability of wine picking cannot be guaranteed, the experience of picking wine workers is different, and it is difficult to evaluate methods and standards. , to achieve the effect of increasing the rate of high-quality wine, ensuring the quality of original wine, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 A kind of method that utilizes the conductivity of original wine to carry out segmental wine picking

[0021] The concrete steps of this embodiment are:

[0022] S1. Take 10kg of raw wine from each of the 6 cellars that have completed the double-round fermentation, and mark them as cellars A1-A6. Distill them under the condition of steam pressure of 0.5mpa, and at 25°C at a speed of 3kg / min. For distilled wine, discard 2kg of wine head for each retort when distilling wine;

[0023] S2. According to the observation of hop size and sensory evaluation, the sommelier divides the original wine into three distillation sections: Shuanglun seasoning, Shuanglun first grade and Shuanglun second grade;

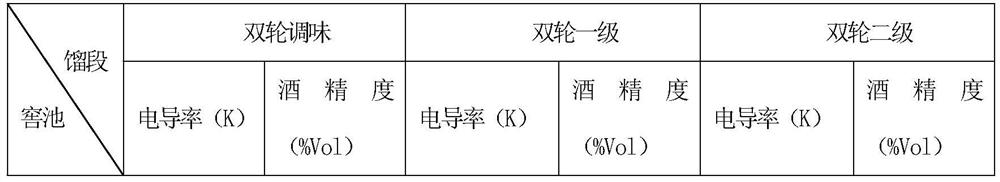

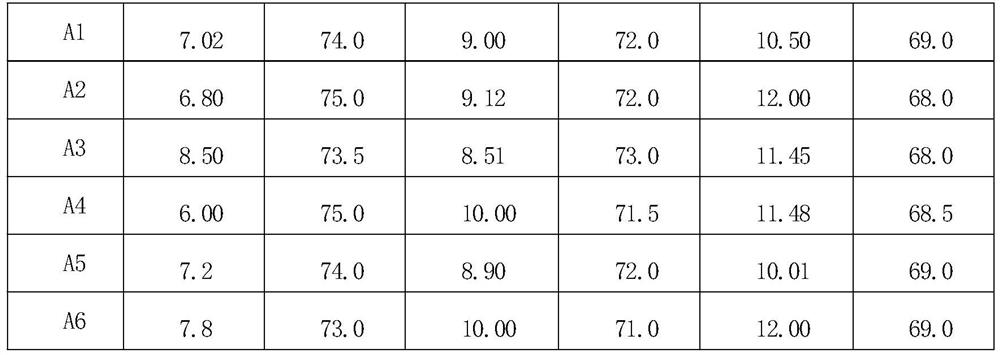

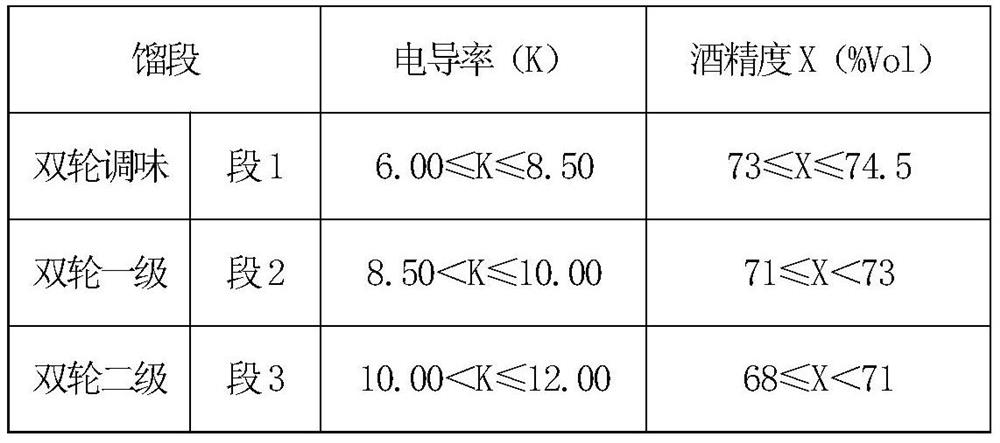

[0024] S3. Measure the electrical conductivity and the alcohol content of each distilled wine in each retort barrel respectively, and obtain the data of each distilled wine electrical conductivity and alcohol content, see Table 1 for details:

[0025] Table 1 The el...

Embodiment 2

[0031] Embodiment 2 A kind of method that utilizes the conductivity of raw wine to carry out segmental wine picking

[0032] The concrete steps of this embodiment are:

[0033] S1. Take 10kg of raw wine from each of the six cellars that have completed a single round of fermentation, and mark them as cellars B1-B6. Distill at a steam pressure of 0.5mpa and at 28°C with a steam pressure of 2.5kg / min. Distilled wine at a high speed, when distilling wine, discard 2kg of wine head for each retort;

[0034] S2. According to the observation of hop size and sensory evaluation, the sommelier divides the original wine into three distillation sections: the first grade of big stubble, the second grade of big stubble and the third grade of big stubble;

[0035] S3. Measure the electrical conductivity and the alcohol content of each distilled wine in each retort barrel respectively, and obtain the data of the electrical conductivity and the alcohol content of each distilled wine, see Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com