Method for improving flavor liquor distillation efficiency

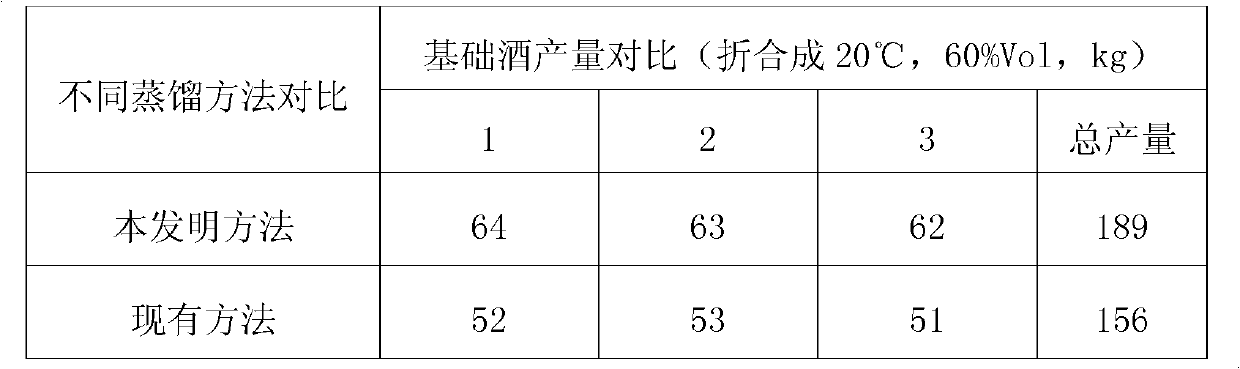

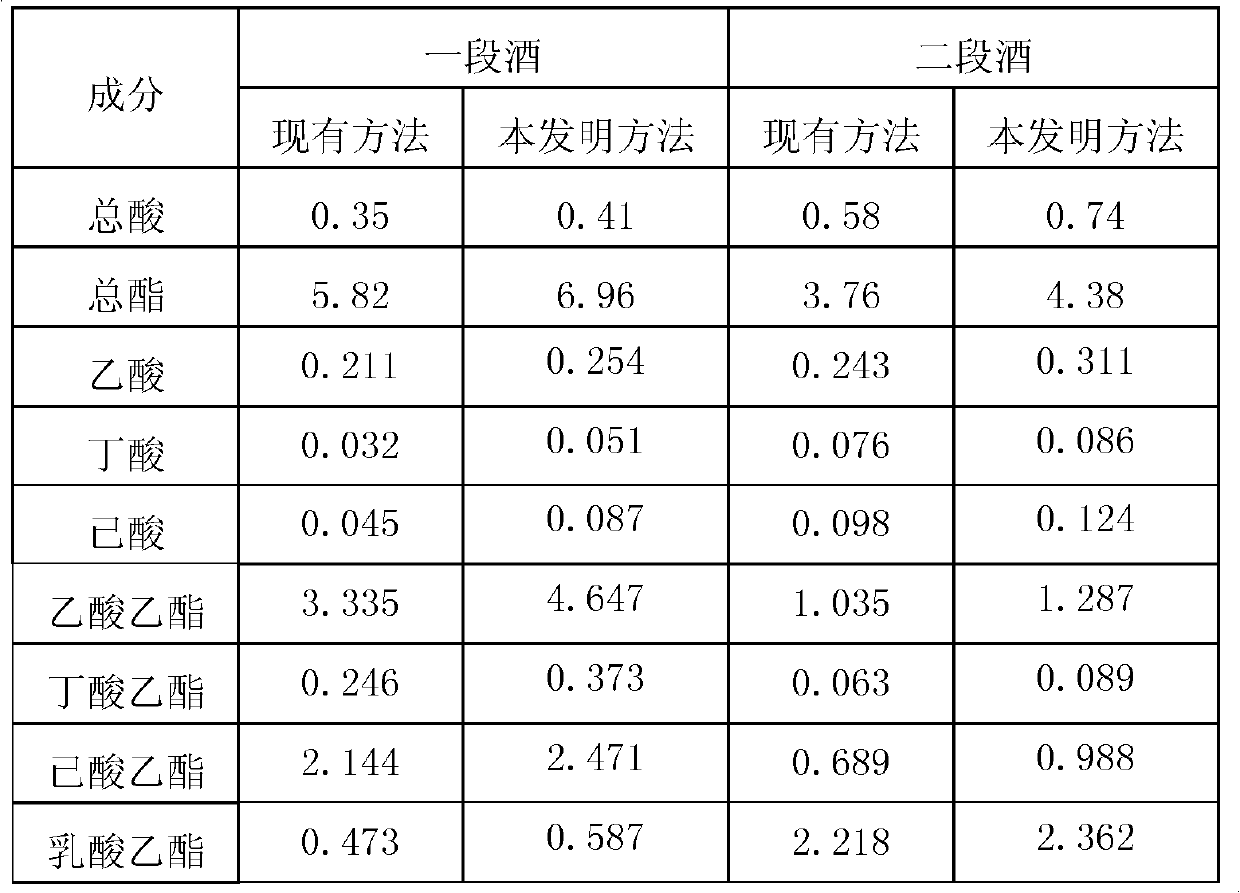

A strong-flavor liquor and high-efficiency technology, which is applied in the field of winemaking, can solve the problems of uncertain retort time, high steam consumption, and unstable flowing wine temperature, and achieves the goal of improving yield and quality, improving distillation efficiency, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method for improving the distilling efficiency of Luzhou-flavor liquor in the present invention comprises selecting retort barrels, taking out cellar grains (exiting cellar grains means grains that have been fermented, waiting for ingredients and steaming wine) and mixing grain and chaff (stirring can be done according to conventional methods) Grain and bran husks), gas detection and upper retort, distillation, wine quantity and quality picking steps, the height of the retort barrel and the diameter ratio of the middle part of the retort barrel are selected to be 0.8~1.8: 1 retort barrel.

[0015] Among them, if the ratio of the height of the retort barrel to the diameter of the middle part of the retort barrel is too large, it will prolong the retort loading time, and due to the influence of its own gravity, it will cause the porosity of the fermented grains to decrease, which will affect the distillation, and it is also not conducive to gas detection and upper retor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com