Rotary compressor

A technology of rotary compressors and rotors, which is applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., and can solve the problems of reciprocating compressors, such as difficulty in balancing the inertial force, short service life of wearing parts, and high processing accuracy. Achieve the effects of reduced friction and wear, reduced weight, and smooth machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

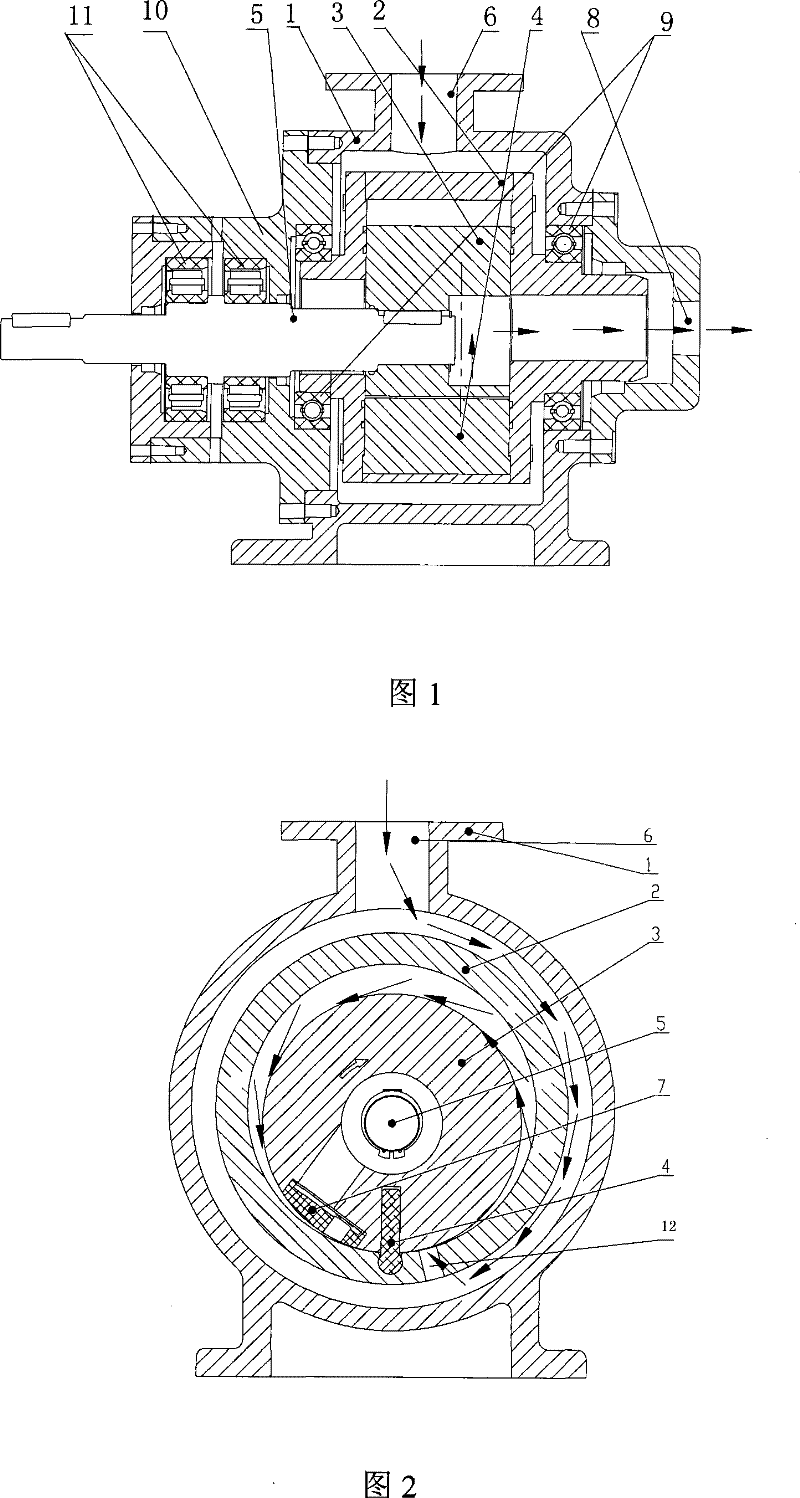

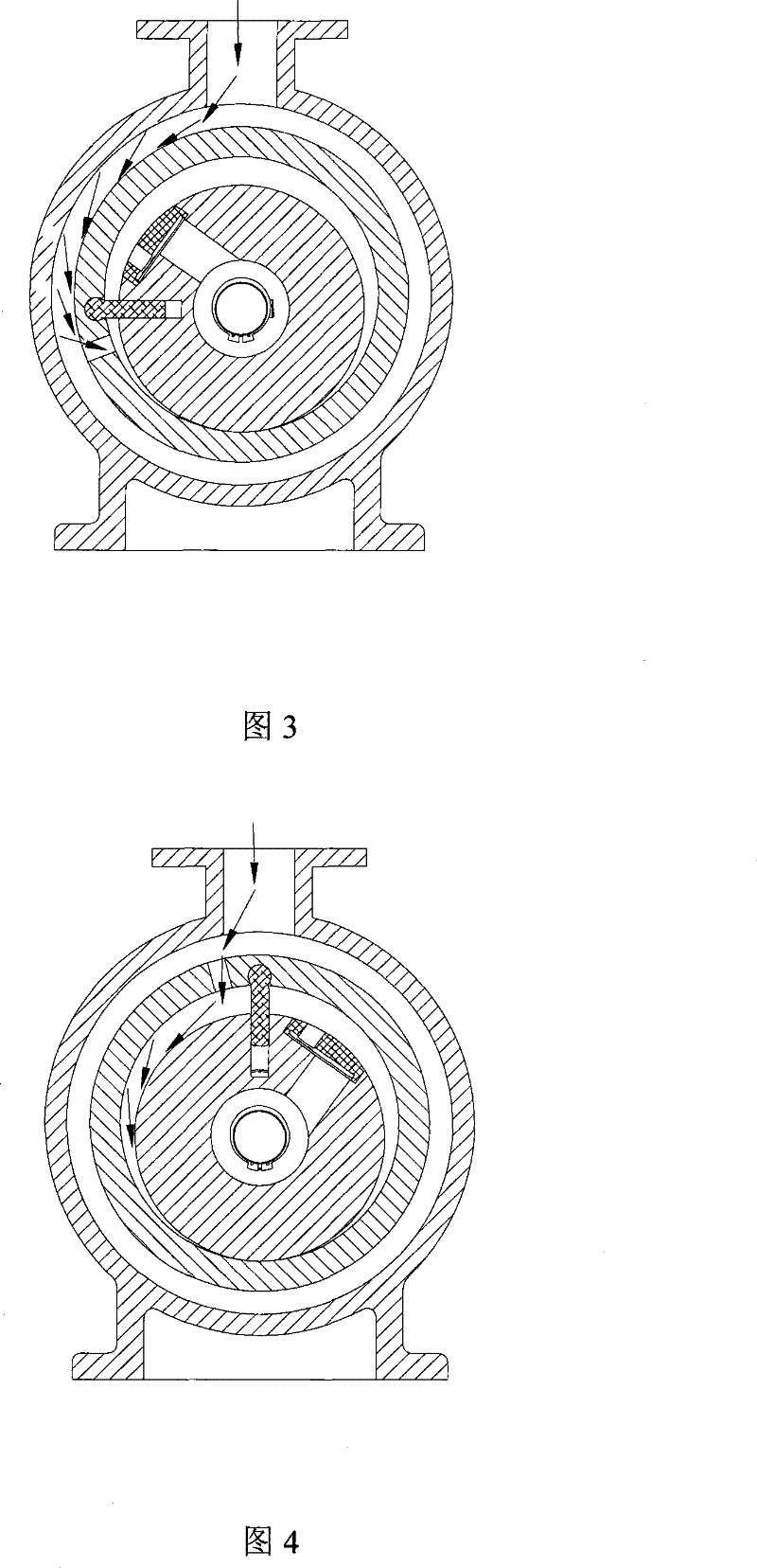

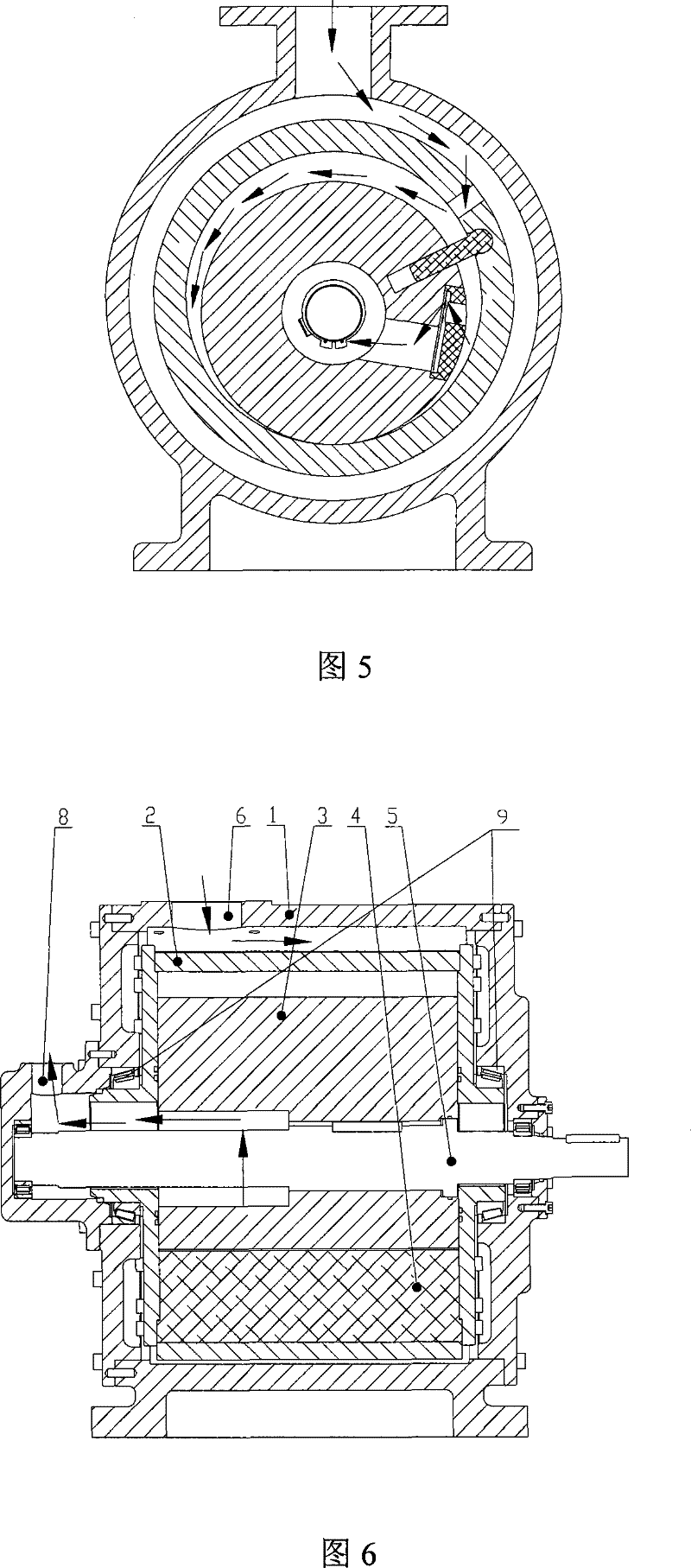

[0024] Such as Figure 1-2 As shown, the first embodiment of the rotary compressor of the present invention includes a casing 1, a cylinder body 2, a rotor 3, a slide plate 4, a main shaft 5, a suction port 6, an exhaust valve 7, an exhaust port 8, and a frame bearing 9. Eccentric seat 10, support bearing 11, cylinder air inlet 12.

[0025] The eccentric seat 10 is fastened together with the casing 1 by bolts, the main shaft 5 is cantilevered on the eccentric seat 10 through the support bearing 11, and the inner side end of the main shaft 5 is connected with the center shaft hole of the rotor 3 through a key and a keyway. That is, the rotor 3 rotates around the central axis of the main shaft 5 .

[0026] Both the cylinder body 2 and the casing 1 are in the shape of a cylinder, one side axial end of the cylinder body 2 is supported on the casing 1 through the frame bearing 9, and the other side axial end of the cylinder body 2 passes through the frame bearing 9 Support on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com