Solenoid and connector assembly

A connector assembly, solenoid technology, applied in transformer/coil connectors, multi-conductor connectors, connections, etc., can solve problems such as failure of related components or controllers, failure of motors or solenoids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or use.

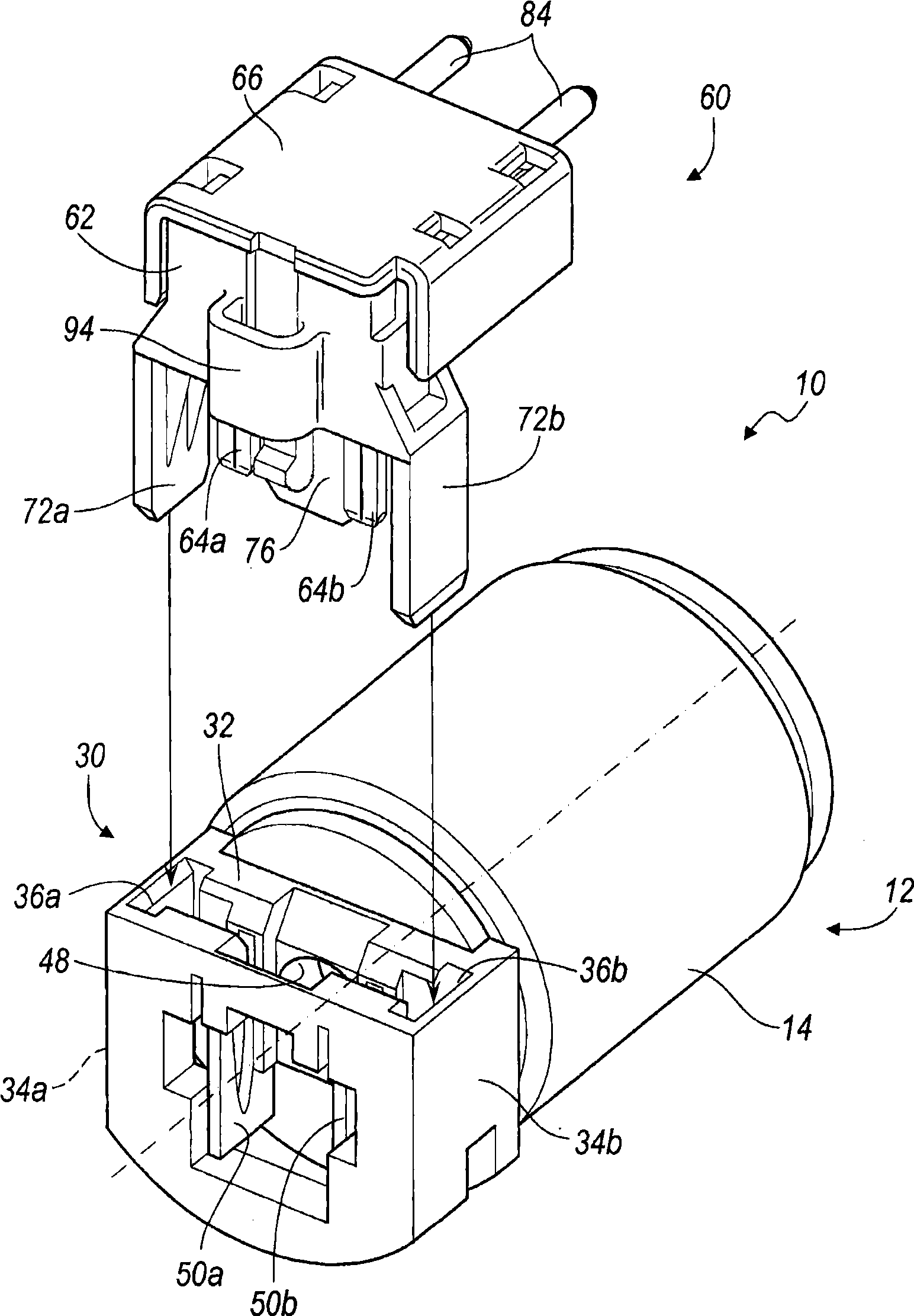

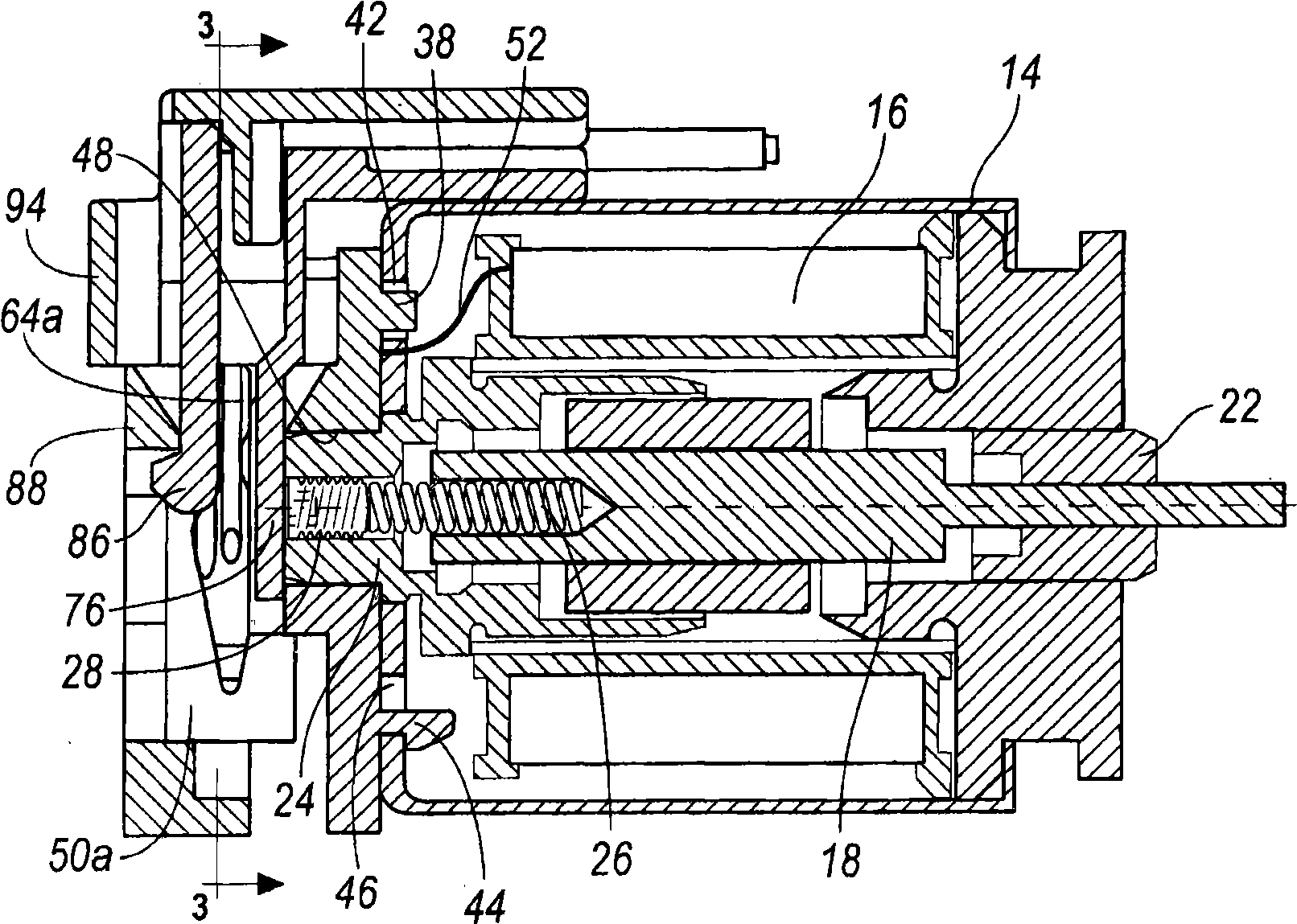

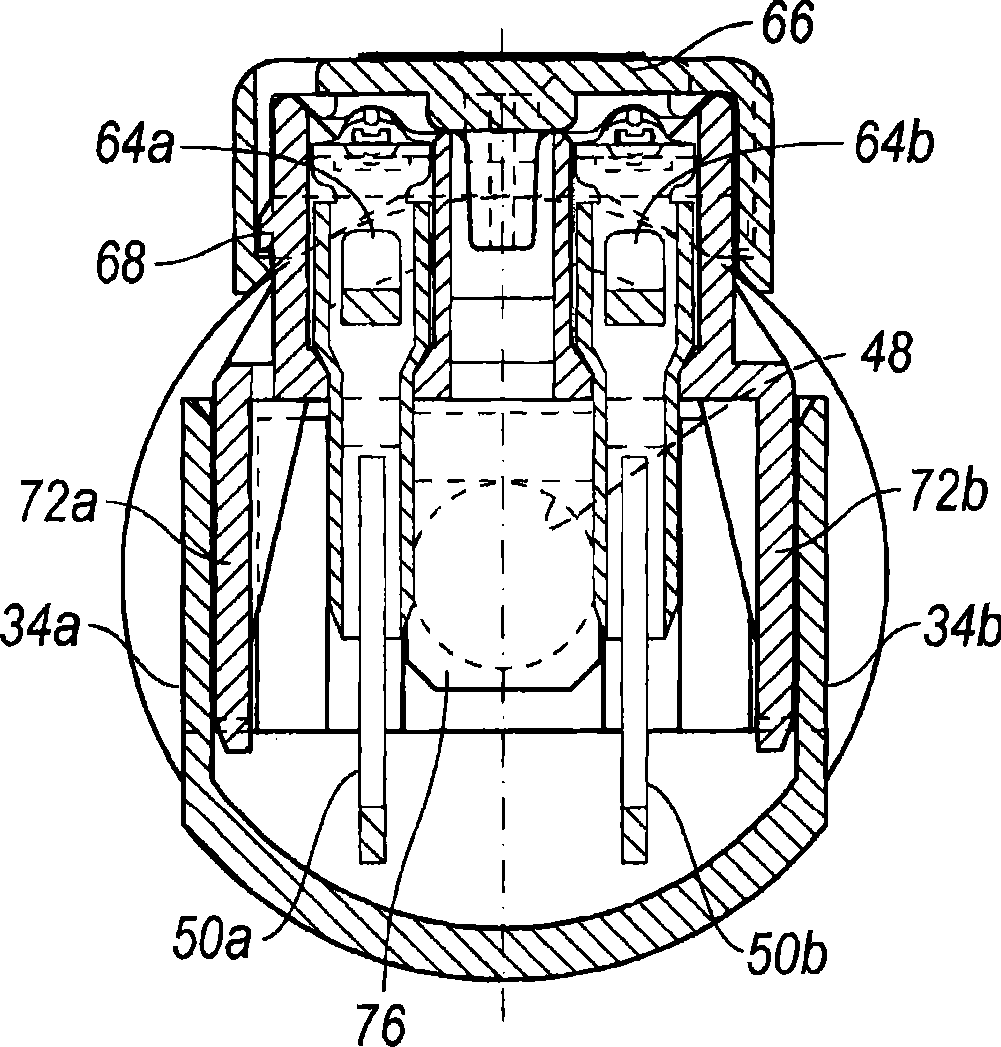

[0023] now refer to figure 1 and figure 2 , depicts a first embodiment of a solenoid and electrical connector assembly and is shown generally at 10 . The solenoid and electrical connector assembly first embodiment 10 includes a solenoid 12 having a generally cylindrical body or housing 14, preferably made of metal, such as steel, aluminum or Alloys of these or other metals. The cylindrical housing 14 positions, supports and protects the electrical coil 16 . The electrical coil 16 generally surrounds a bidirectionally translatable armature or plunger 18 . This plunger 18 cooperates with a first axial guide or bearing 22 and a second axial guide, pole piece or stop 24, said first axial guide or bearing 22 and a second axial guide, pole The plates or stops 24 together define an axis of movement or translation of the plunger 18 . A portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com