Chip-component-mounted device and semiconductor device

A mounting body, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of low connection reliability, weak connection strength, poor connection strength, etc., to increase the contact area, The effect of stable connection strength, stable position and inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

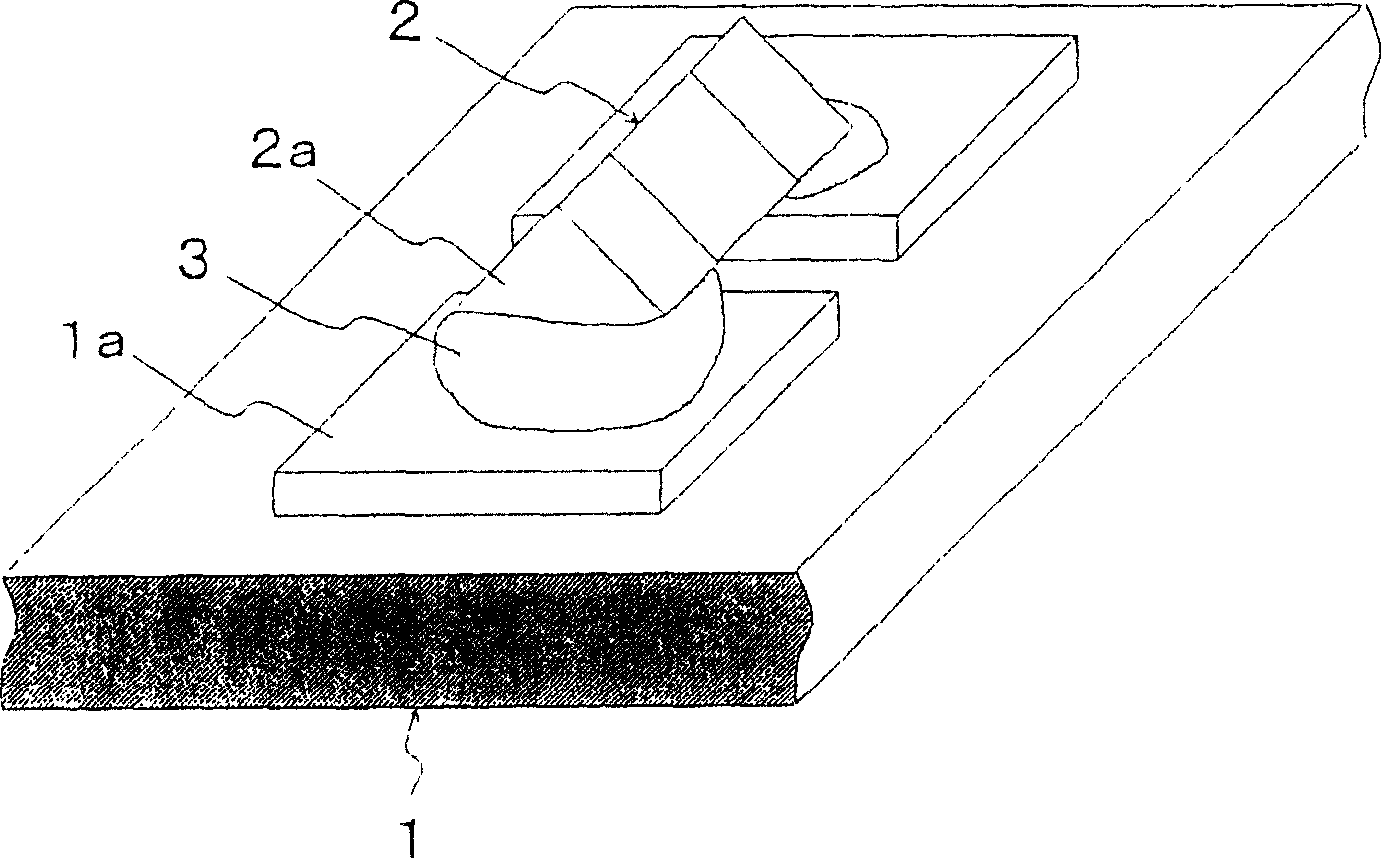

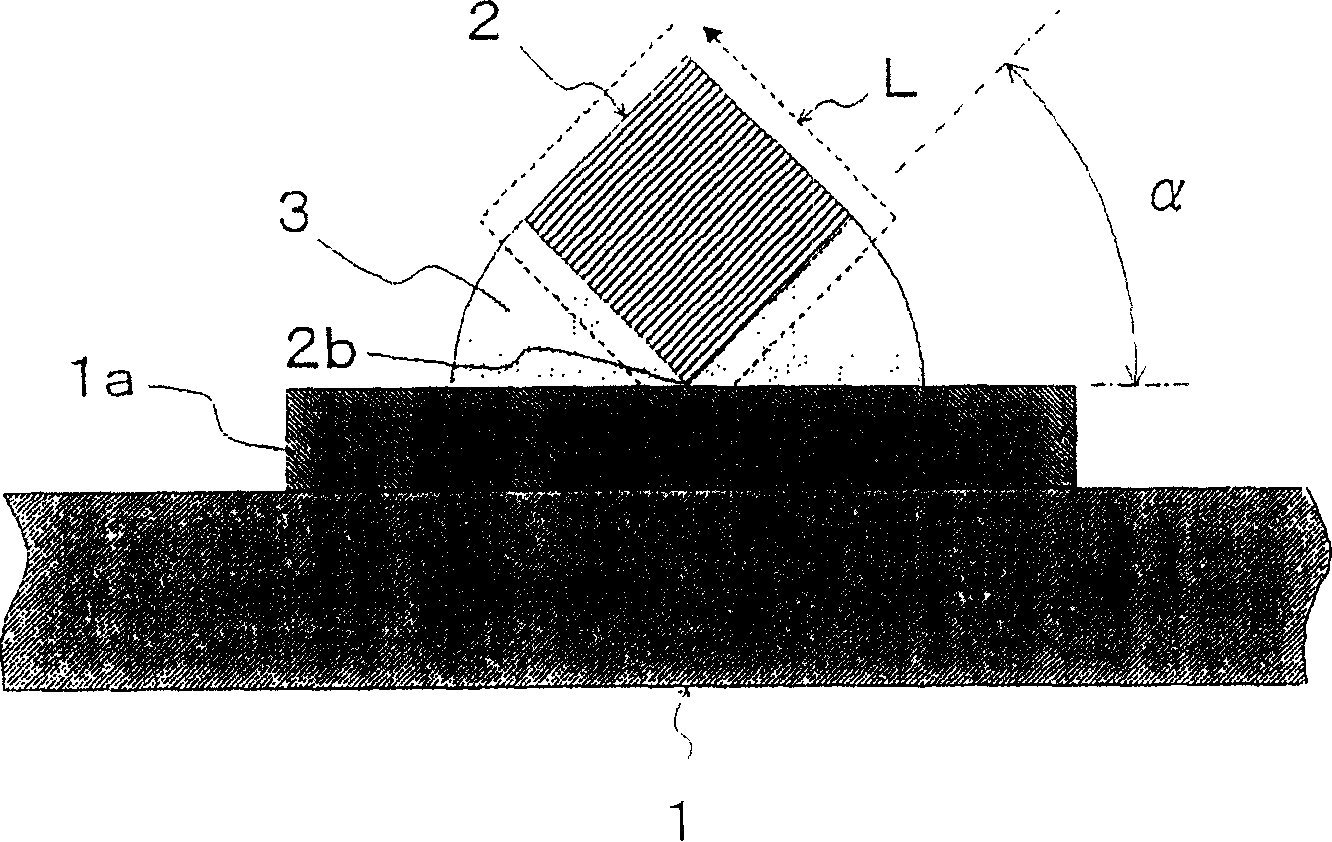

[0026] In Embodiment 1, on the two land portions 1a (connected portions) of the printed wiring board 1 on which a semiconductor element (not shown) is mounted, the chip component 2 is arranged across the two land portions 1a, and the chip component The corner portion 2b of 2 is mounted facing the land portion 1a side. The pad portion 1 a and the corresponding electrode portion 2 a are physically and electrically connected by the conductive adhesive 3 . The pad portion 1a of the printed wiring board 1 is a conductive pad formed on the surface of the wiring (not shown) of the printed wiring board 1, and is made of noble metal such as Au. The corresponding land portions 1 a are arranged at predetermined intervals. The chip component 2 is an electronic component such as a capacitor, a resistor, or an inductor, and is a chip-shaped electronic component having at least a corner portion 2b, and has electrode portions 2a at both ends. The electrode portion 2a of the chip component 2...

Embodiment approach 2

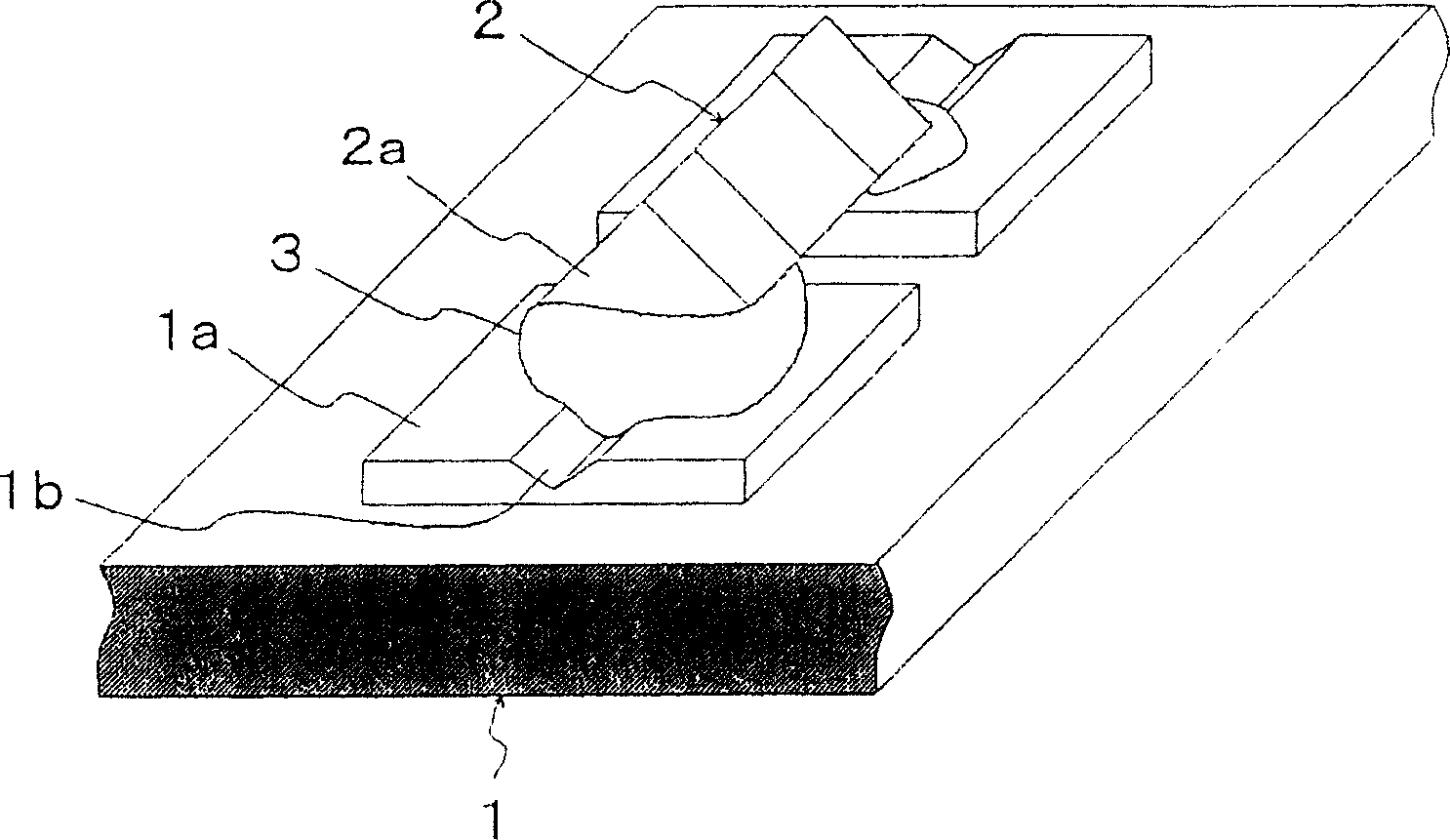

[0030]In Embodiment 2, as in Embodiment 1, on two pad portions 1a (connected portions) of a printed wiring board 1 on which a semiconductor element (not shown) is mounted, a chip component 2 straddles between the two pad portions 1a. However, it is arranged so that the corner portion 2b of the chip component 2 is mounted facing the pad portion 1a side. The pad portion 1 a and the corresponding electrode portion 2 a are physically and electrically connected by the conductive adhesive 3 . The pad portion 1a of the printed wiring board 1 is a conductive pad formed on the surface of the wiring (not shown) of the printed wiring board 1, and is made of noble metal such as Au. The corresponding land portions 1 a are arranged at predetermined intervals. The chip component 2 is an electronic component such as a capacitor, a resistor, or an inductor, and is a chip-shaped (for example, rectangular parallelepiped, cubic) electronic component having at least corners 2b, and has electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com