Compact water-cooling three phase asynchronous motor

A three-phase asynchronous motor technology, applied in the field of motors, can solve the problems of large volume of cooling devices, poor cooling effect, large installation space, etc., and achieve the effects of increasing cooling area, prolonging service life and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

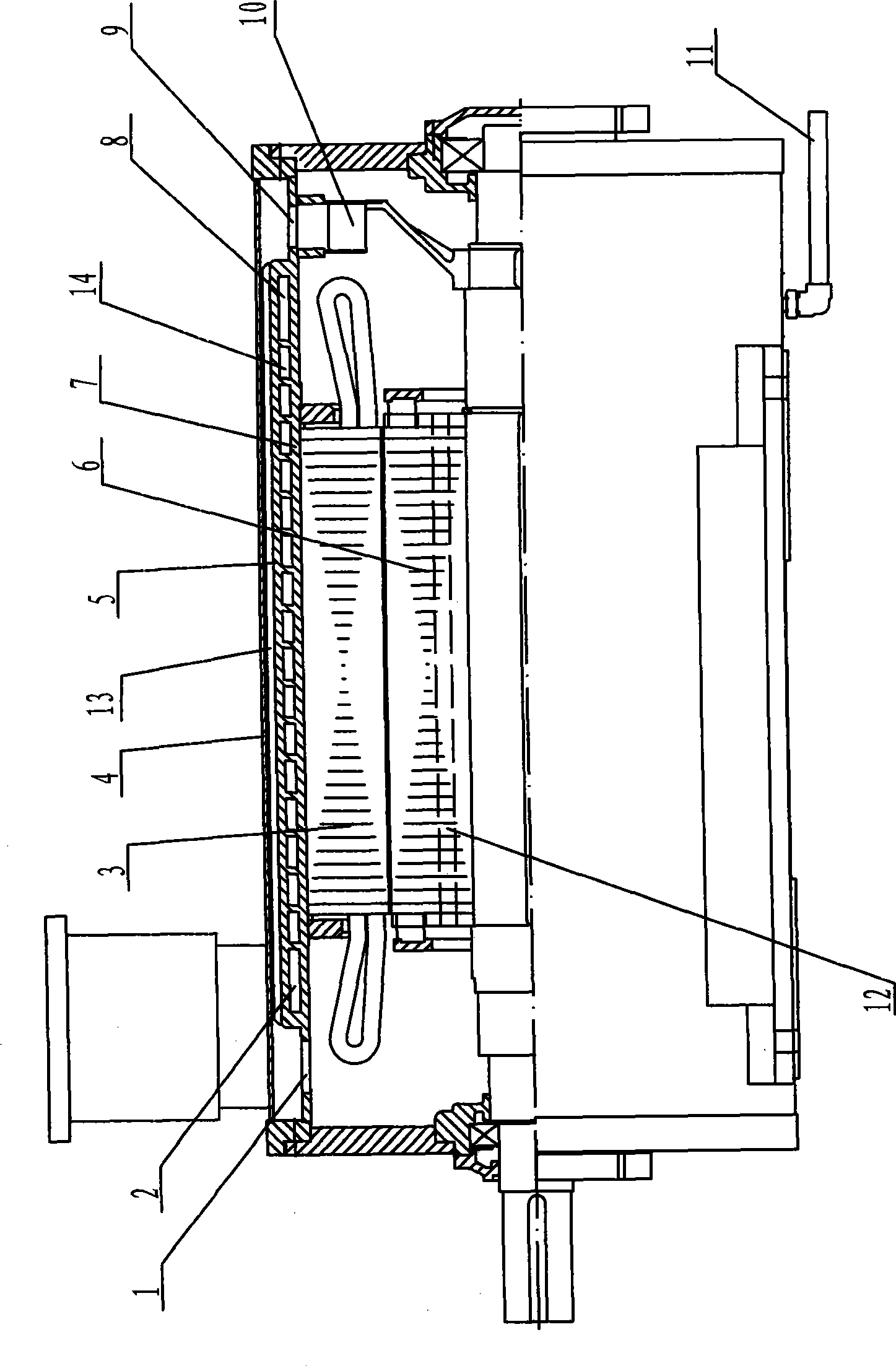

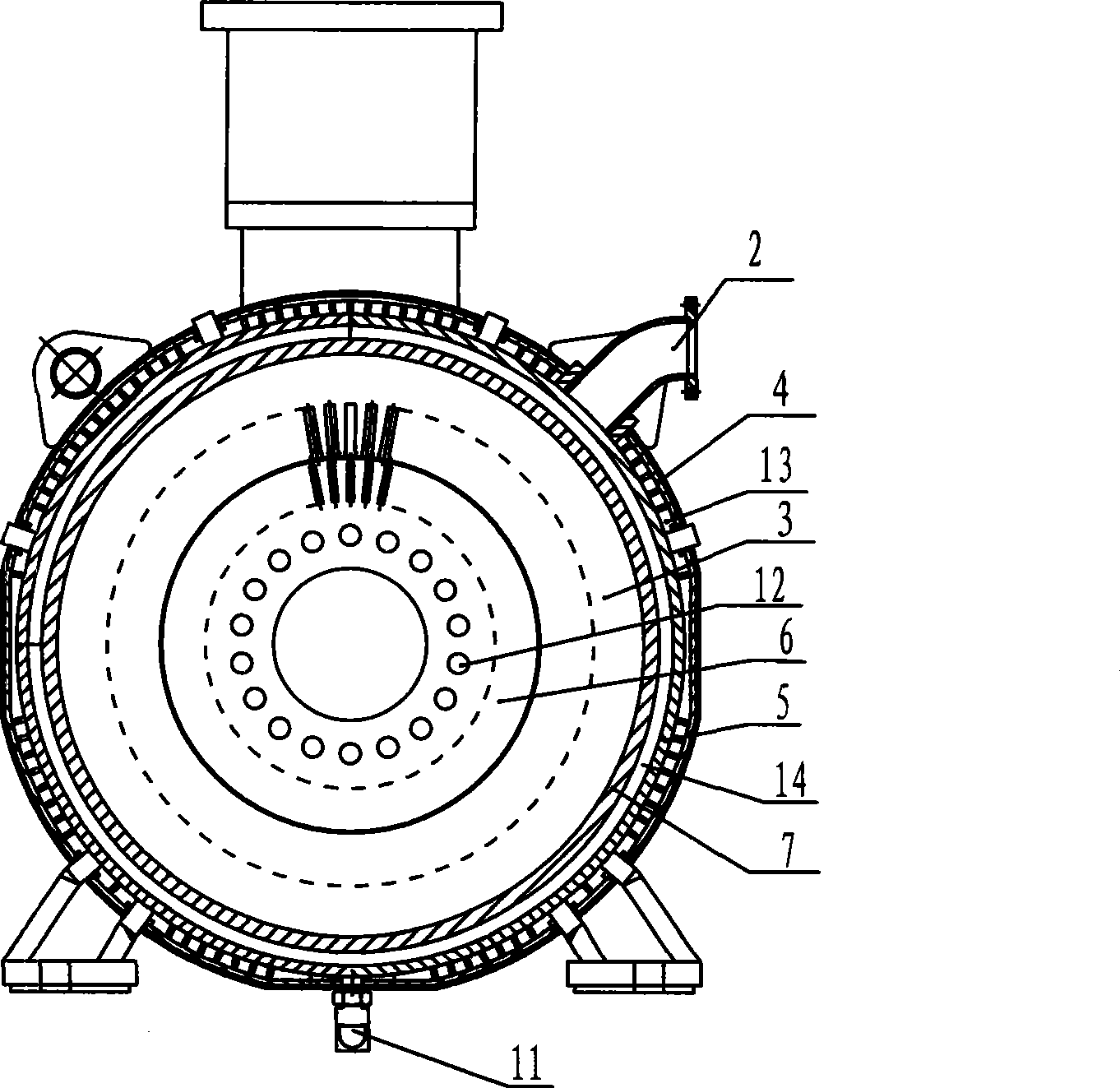

[0008] Such as figure 1 , figure 2 As shown, the compact water-cooled three-phase asynchronous motor includes a stator 3, a rotor 6, a cooling device and a casing 4. The cooling device adopts air-water composite cooling, and the cooling device includes an internal circulation air path and a water circulation channel; the water jacket covers the outside of the motor stator core 3, and is composed of an inner water jacket 7 and an outer water jacket 5, and a water channel 14 is arranged in the middle. It can be a radial spiral water channel or an axial reciprocating water channel. The two ends of the water channel are provided with a water inlet 2 and a water outlet 8. The cooling water exhaust channel 11 is directly below the motor and connected to the water channel 14; the outer water jacket 5 and the outer casing 4 Between is cooling air channel 13.

[0009] The internal circulating air is composed of a fan 10 , an air inlet 9 , a cooling air duct 13 , an air outlet 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com