Royal jelly digging machine

A technology of royal jelly and jelly machine, which is applied in application, beekeeping, animal husbandry, etc. It can solve the problems of destroying the natural block of royal jelly and affecting the preservation function of royal jelly, so as to improve the nutritional value and preservation period and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

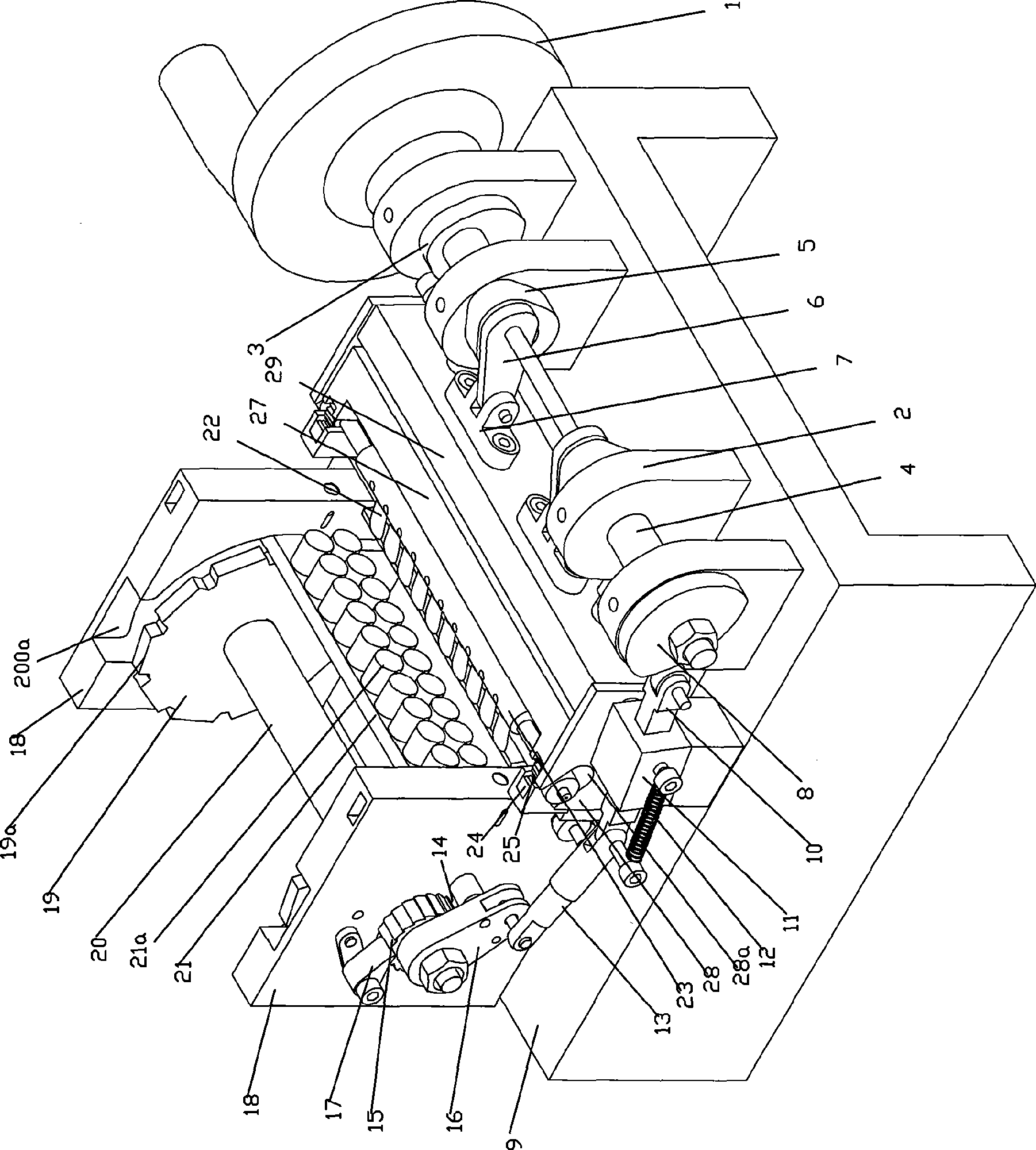

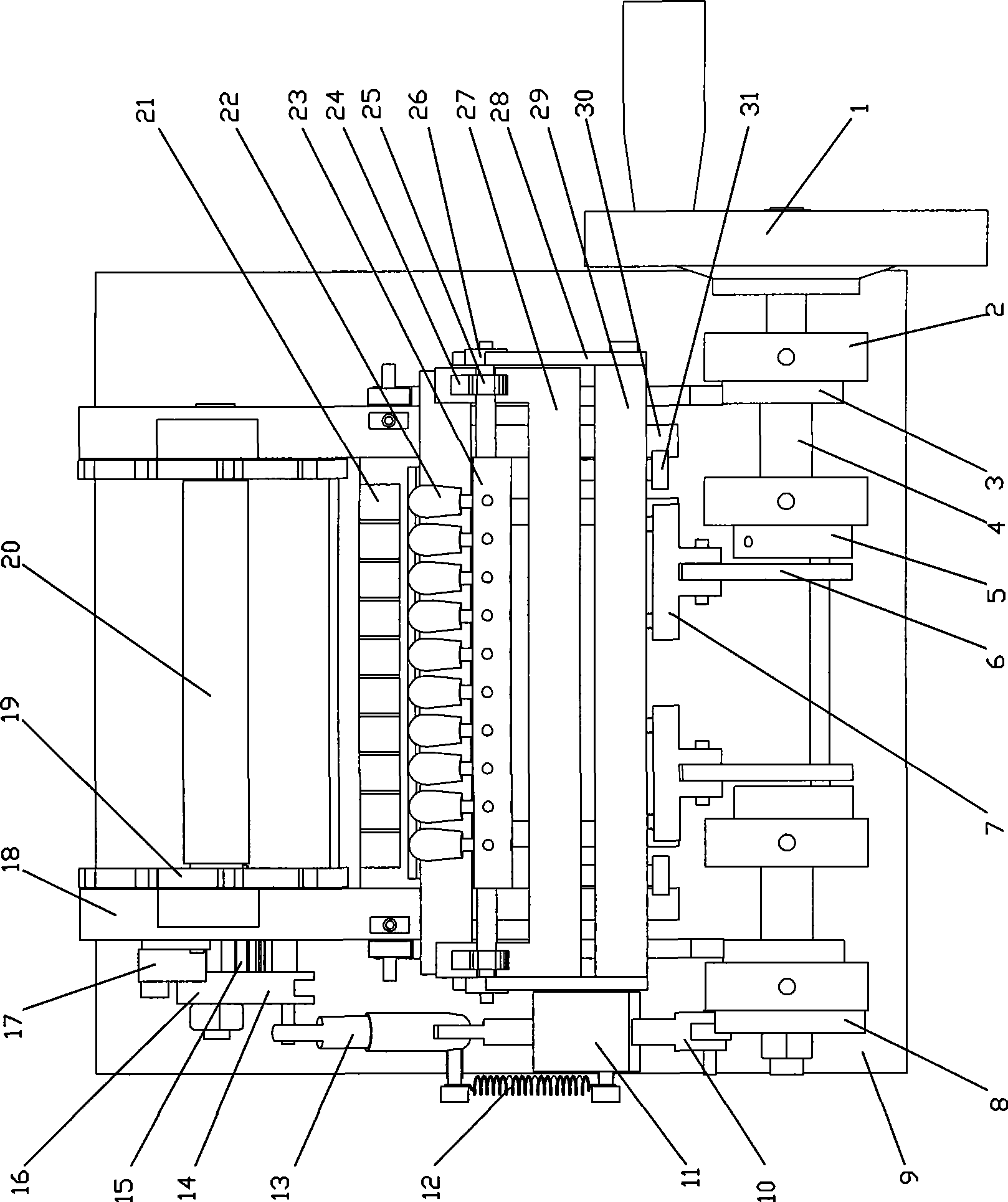

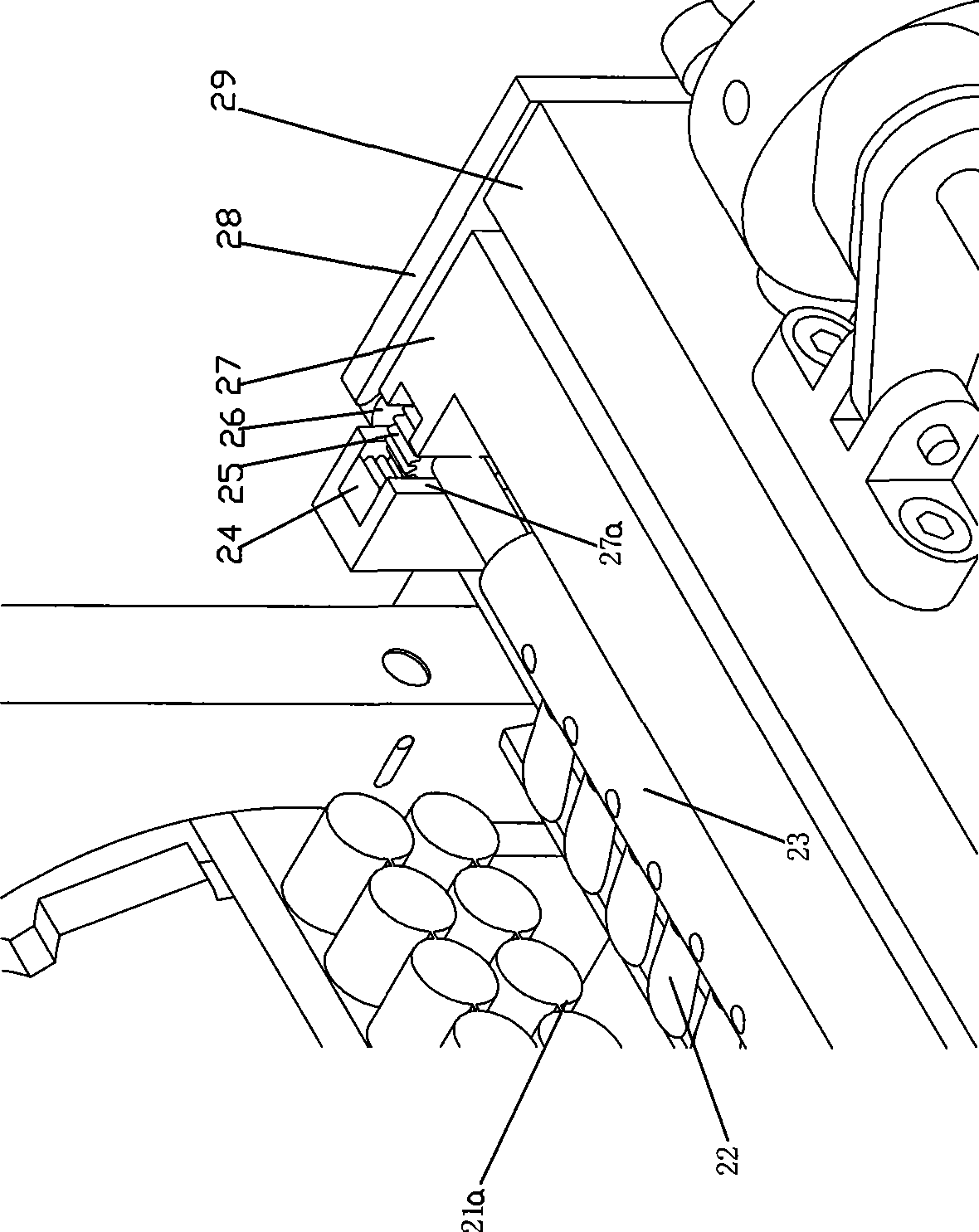

[0026] Refer to attached picture. Royal jelly dredger provided by the present invention comprises base 9, also comprises following structure:

[0027] (1). The rotary conveying mechanism includes a first positioning mechanism for the base strip 21 on the rotary conveying mechanism.

[0028] Along the rotary motion direction of the rotary conveying mechanism, the royal jelly dredger has an input area 100a where the base strip enters the rotary conveying mechanism, a discharge area 100b that leaves the rotary conveying mechanism, and a dredging area 100c between the input area and the discharging area , the input area 100a, the discharge area 100b, and the dredging area 100c are three open areas on the surface of the rotary conveying mechanism of the royal jelly dredger to the outside world, so that the platform base strips are sent into the rotary conveying mechanism, and the slurry is dredged. The working head extends into the base strip to dig out the slurry and discharge th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com