Non-gaseous coating apparatus

An airless spraying, cylinder technology, applied in coating, spraying device, liquid spraying device and other directions, can solve the problems of cylinder leakage, short service life, large air consumption, etc., to increase the service life and reduce the loss of gas , Improve the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

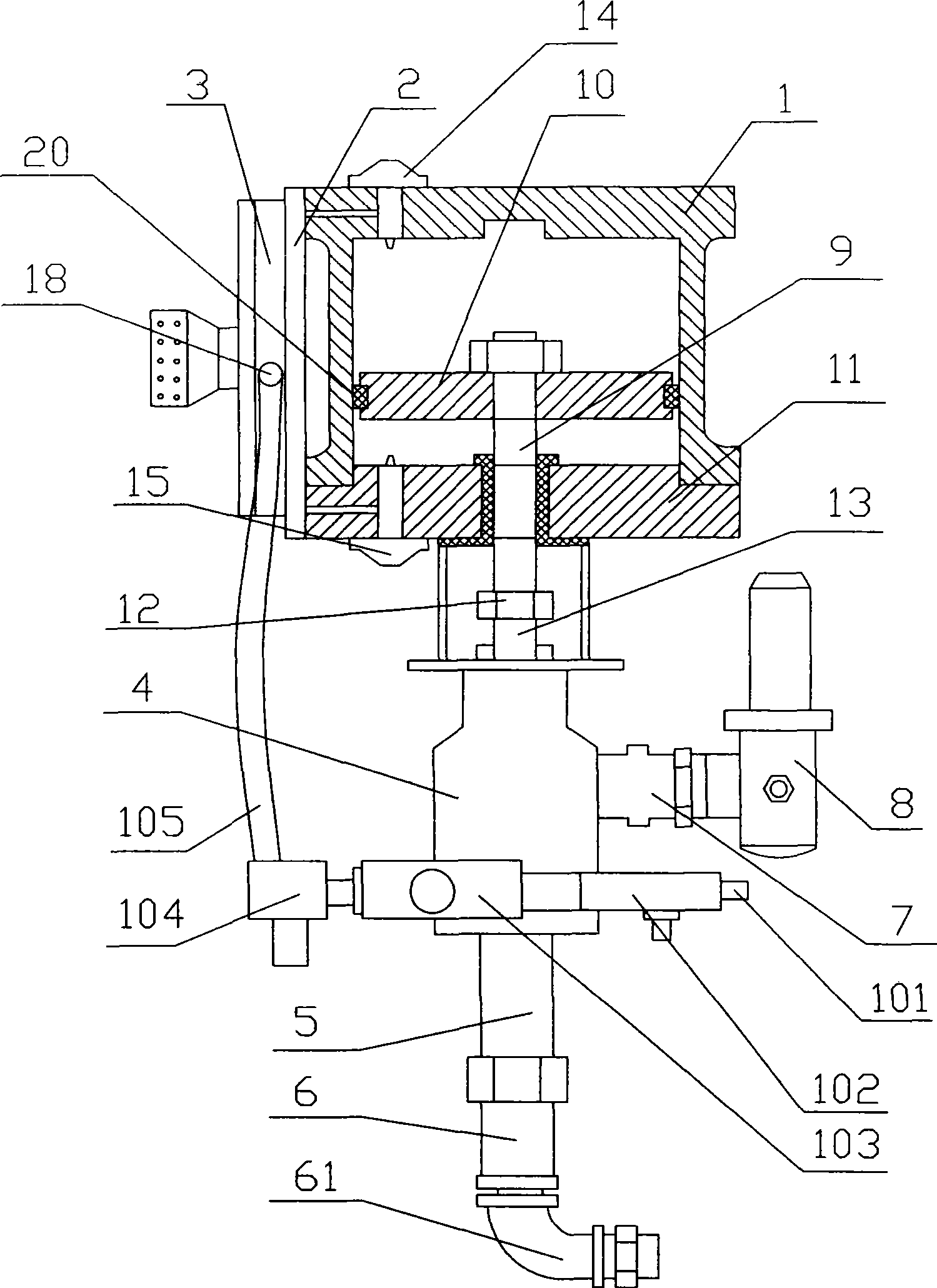

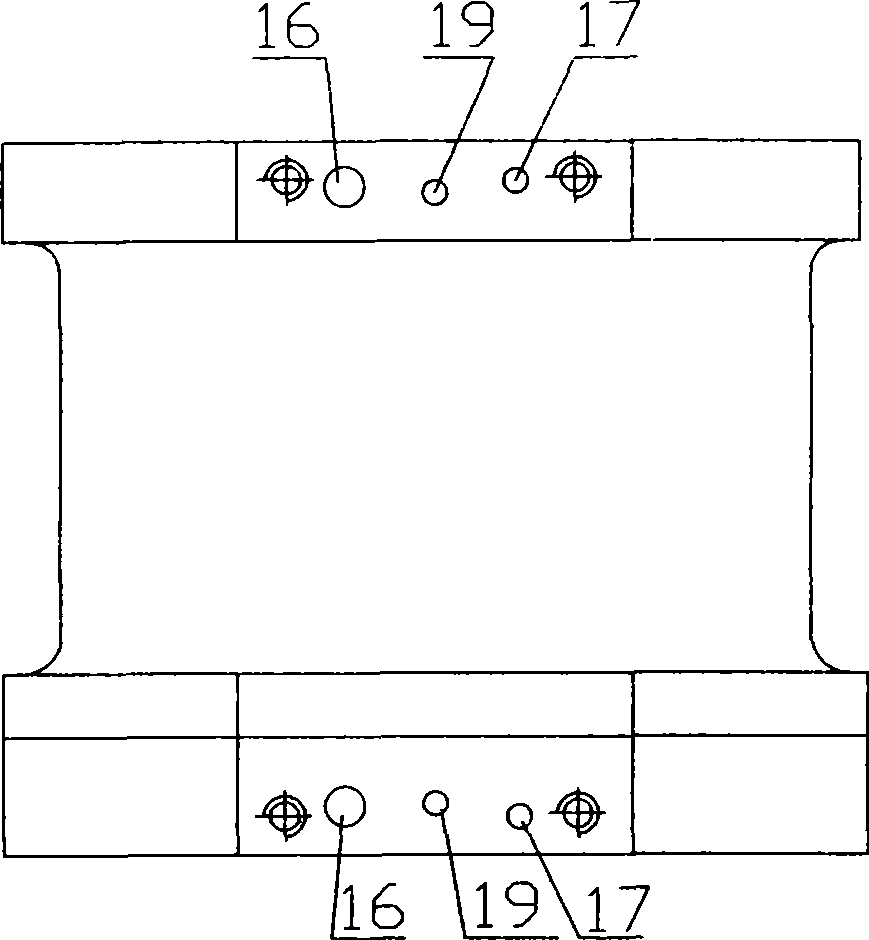

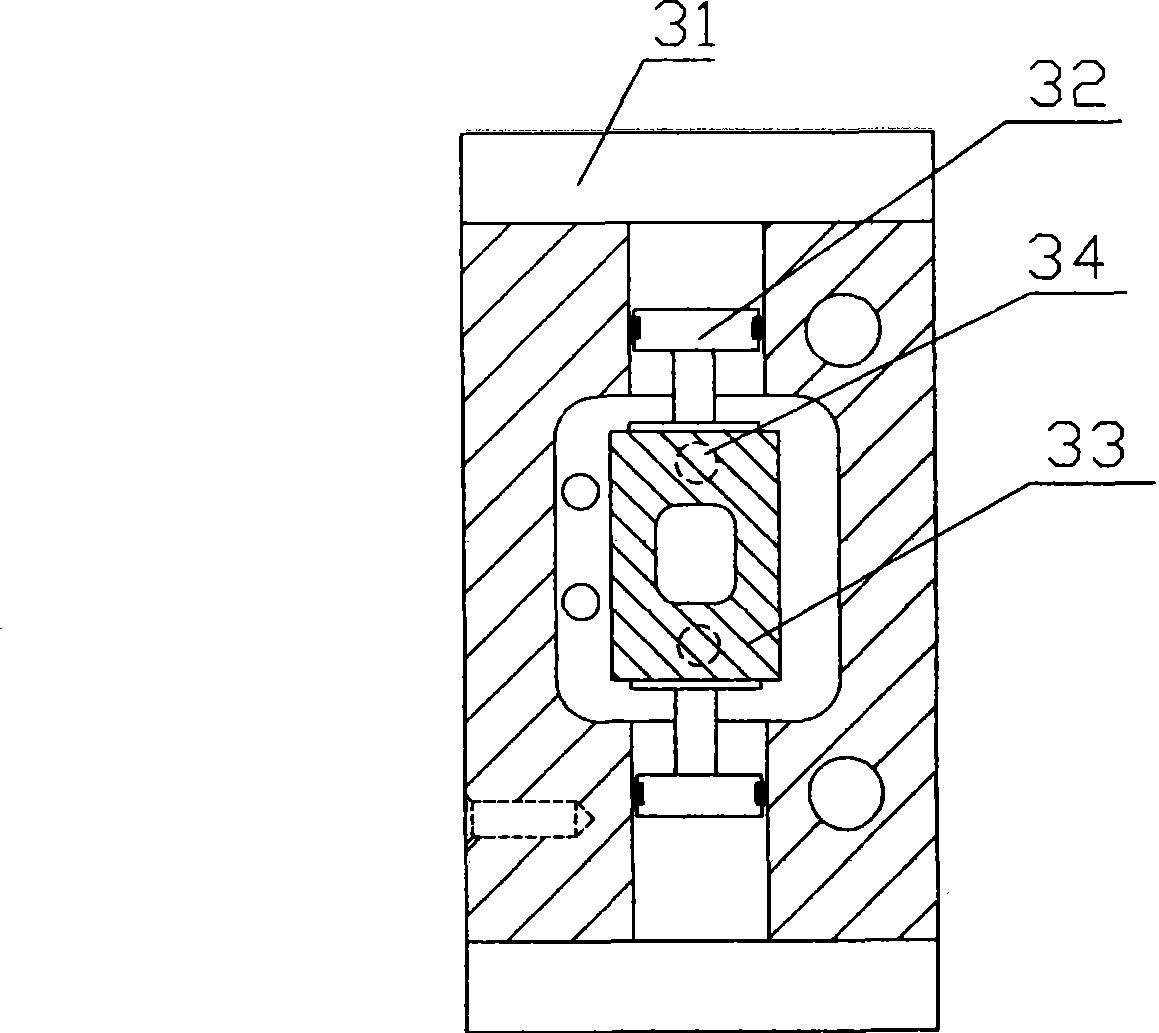

[0028] refer to figure 1 , figure 2 As shown, it is a preferred embodiment of the present invention, an airless spraying machine, including a cylinder 1, a chassis 11, an air distribution block assembly 2, a reversing chamber assembly 3, a pump seat assembly 4, a paint cylinder 5, Suction valve body 6, output joint 7, filter assembly 8, air intake joint 101, air intake tee 102, air intake filter element 103, lubricator 104 and air intake hose 105, wherein the cylinder 1 is closed and connected to the chassis 11 , the gas distribution block assembly 2 is closed and connected with the reversing chamber assembly 3, and an upper piston rod 9 and a piston 10 sleeved on the upper piston rod 9 are arranged in the cylinder 1, and one end of the upper piston rod 9 passes through the cylinder The lower cover 11 is connected with the lower piston rod 13 through the connecting head 12, and the pump seat assembly 4 is sleeved on the lower piston rod 13, and the paint cylinder 5 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com