Assembly type prefabricated wall construction method

A technology of prefabricated walls and construction methods, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor durability and fire resistance of thermal insulation materials, and achieve the effects of reducing comprehensive costs, improving resource utilization efficiency, and ensuring construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly.

[0026] The present invention includes:

[0027] In order to solve the above-mentioned technical problems, a technical solution adopted in the present invention is a kind of assembly type prefabricated wall body construction method, carries out successively according to the following steps:

[0028] Step 1 Leveling of the base layer; use 1:2 cement mortar to level the operation surface, and cover the isolation layer on the leveling layer before laying bricks;

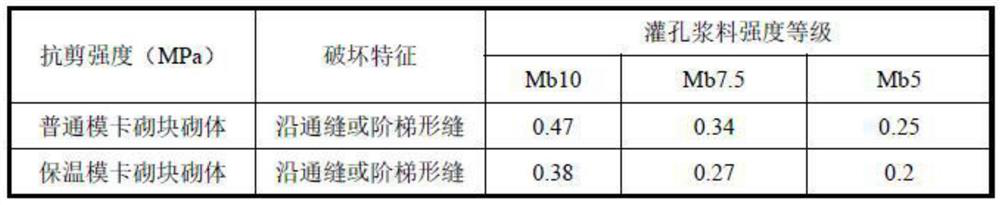

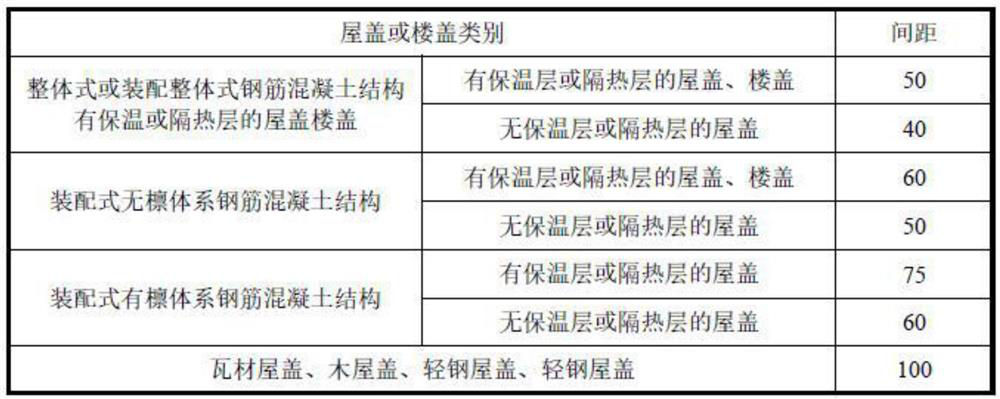

[0029] Step 2 Arranging blocks and laying bricks; according to the design drawings, arrange blocks and lay bricks on the leveling layer. The upper and lower skins of the modular block should be overlapped with holes and staggered j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com