Graphene-loaded grain refinement material of Al-Mg alloy wire and preparation method of graphene-loaded grain refinement material

A grain refinement and graphene technology, applied in the field of graphene-loaded grain refinement materials and their preparation, can solve the problem that the electrical conductivity, strength and plasticity of aluminum-magnesium alloy wires need to be improved, product performance cannot be fully exploited, and product performance cannot be fully exploited. Excavate product and other problems to achieve the effect of complete and thorough fusion, good strength and plastic coordination, and reduced material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A graphene composite loaded grain refinement material of Al-Mg alloy wire, Gp0.10%, V0.10%, Zr0.10%, Mn0.20%, Ti0.20%, Fe0.40 by weight percentage %, Si0.08%, Cr0.20%, Cu0.40%. Its preparation method comprises the following steps:

[0035] (1) Under argon protection, Gp0.10%, V0.10%, Zr0.10%, Mg3.8%, Mn0.20%, Ti0.20%, Fe0.40%, Si0. 08%, Cr0.20%, Cu0.40%, etc. uniformly mix the grain refinement powder, and then use the tablet machine at 2.0×10 6 Under the pressure of Pa, the mixed powder is cold pressed into a sheet sample;

[0036] (2) Put the flake sample into a resistance sintering furnace filled with argon gas protection, adopt the intermediate continuous double-stage temperature-raising annealing method in the sintering process, and adopt the gradient heating and temperature-raising annealing method, that is, use the above grain refiner metal The temperature of phase transition and microstructure change is usually between 500-1500°C. At the midpoint of this tempe...

Embodiment 2

[0040] A graphene composite loaded grain refinement material of Al-Mg alloy wire, Gp0.20%, V0.20%, Zr0.20%, Mn0.20%, Ti0.20%, Fe0.40 by weight percentage %, Si0.08%, Cr0.20%, Cu0.40%. Its preparation method comprises the following steps:

[0041] (1) Under the protection of argon, the percentages by weight are Gp0.20%, V0.20%, Zr0.20%, Mn0.20%, Ti0.20%, Fe0.40%, Si0.08%, Cr0.20%, Cu0.40%, etc. uniformly mix the grain refinement powder, and then use the tablet machine to 6 Under the pressure of Pa, the mixed powder is cold pressed into a sheet sample;

[0042] (2) Put the flake sample into a resistance sintering furnace filled with argon gas protection, adopt the intermediate continuous double-stage temperature-raising annealing method in the sintering process, and adopt the gradient heating and temperature-raising annealing method, that is, use the above grain refiner metal The temperature of phase transition and microstructure change is usually between 500-1500°C. At the m...

Embodiment 3

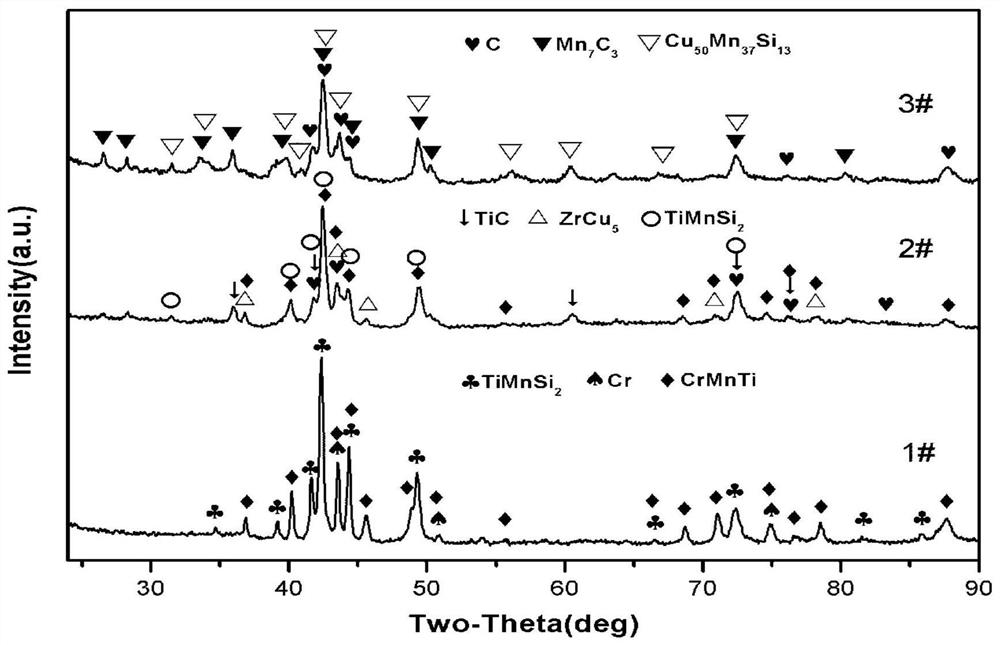

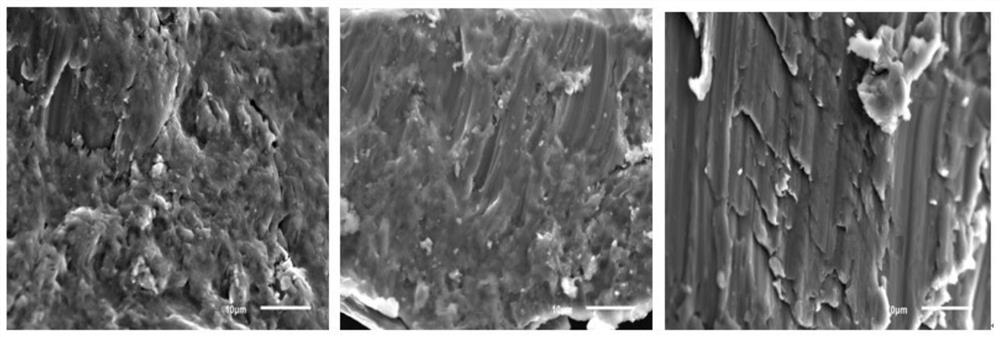

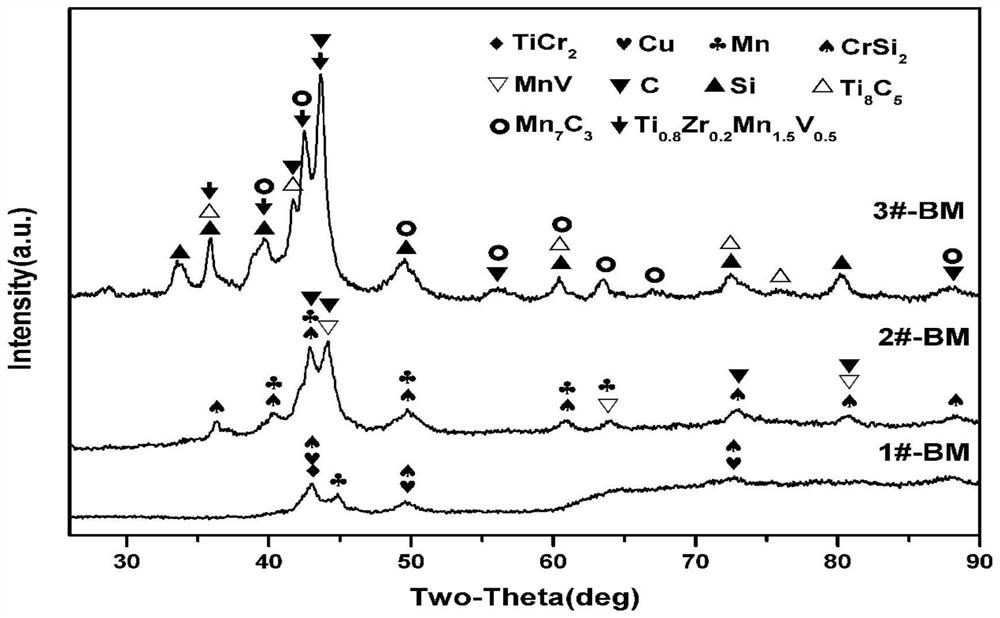

[0052] One, according to the component proportioning of the present invention, made three kinds of intermediate grain refinement alloy samples, are respectively 1# sample, 2# sample and 3# sample, and its composition ratio is as follows:

[0053] The weight percentage of 1# sample composition is: Mn0.20%, Ti0.20%, Si0.04%, Cr0.20%, Cu0.40%, namely Mn-2g, Ti-2g, Si-0.4g, Cr-2g , Cu-4g, a total of 10.4g.

[0054] 2# sample composition weight percentage is: Gp0.10%, V0.10%, Zr0.10%, Mn0.20%, Ti0.20%, Si0.04%, Cr0.20%, Cu0.40%, namely Gp -1g, V-1g, Zr-1g, Mn-2g, Ti-2g, Si-0.4g, Cr-2g, Cu-4g. Total 13.4g

[0055] The weight percentage of the 3# sample composition is: Gp0.20%, V0.20%, Zr0.20%, Mn0.20%, Ti0.20%, Si0.04%, Cr0.20%, Cu0.40%, namely Gp -2g, V-2g, Zr-2g, Mn-2g, Ti-2g, Si-0.4g, Cr-2g, Cu-4g, total 16.4g

[0056] 2. Sintering: first press the intermediate alloy material of 1# sample, 2# sample and 3# sample, heat it to 750°C and keep it for 2h, then heat it to 950°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com