Tool for mounting lower prestressing nut

An installation tool and prestressing technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of damaged tie rod threads or prestressed nut threads, complicated structure of auxiliary installation tools, and increased labor intensity of workers. Reduce installation time, large industrial utilization value, good installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

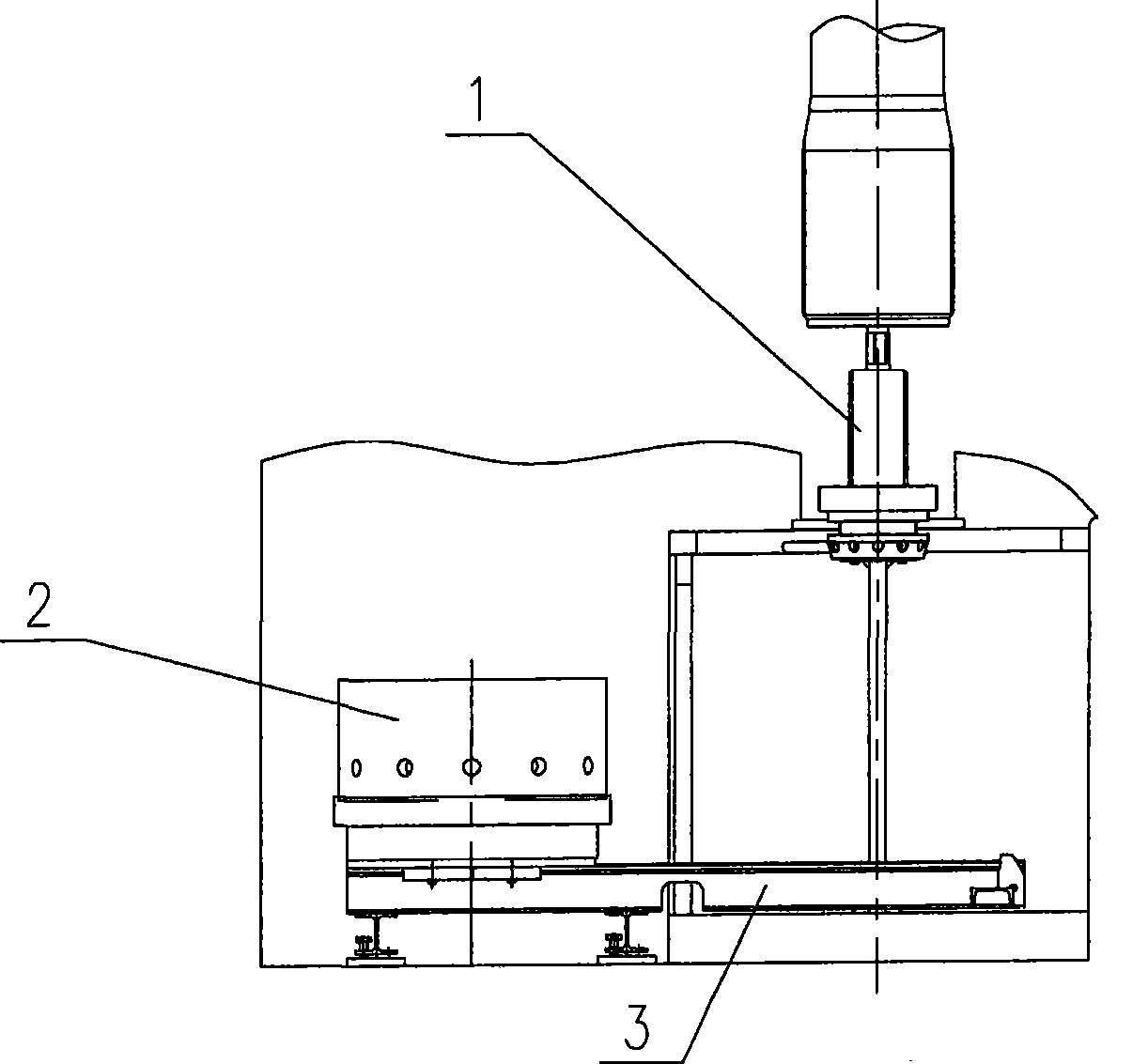

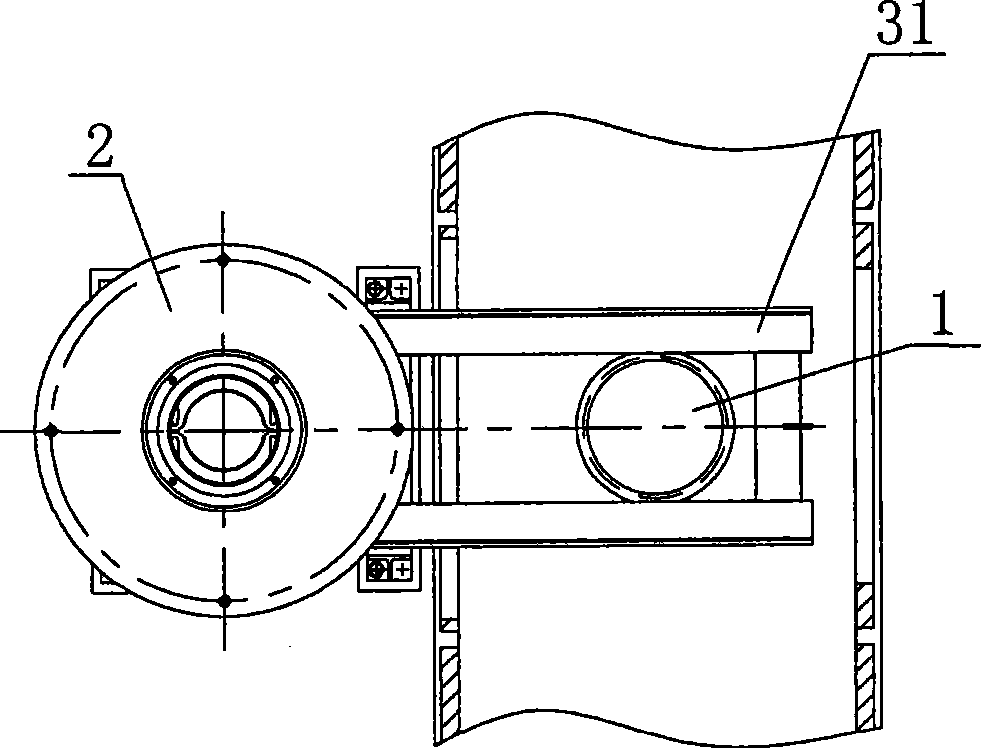

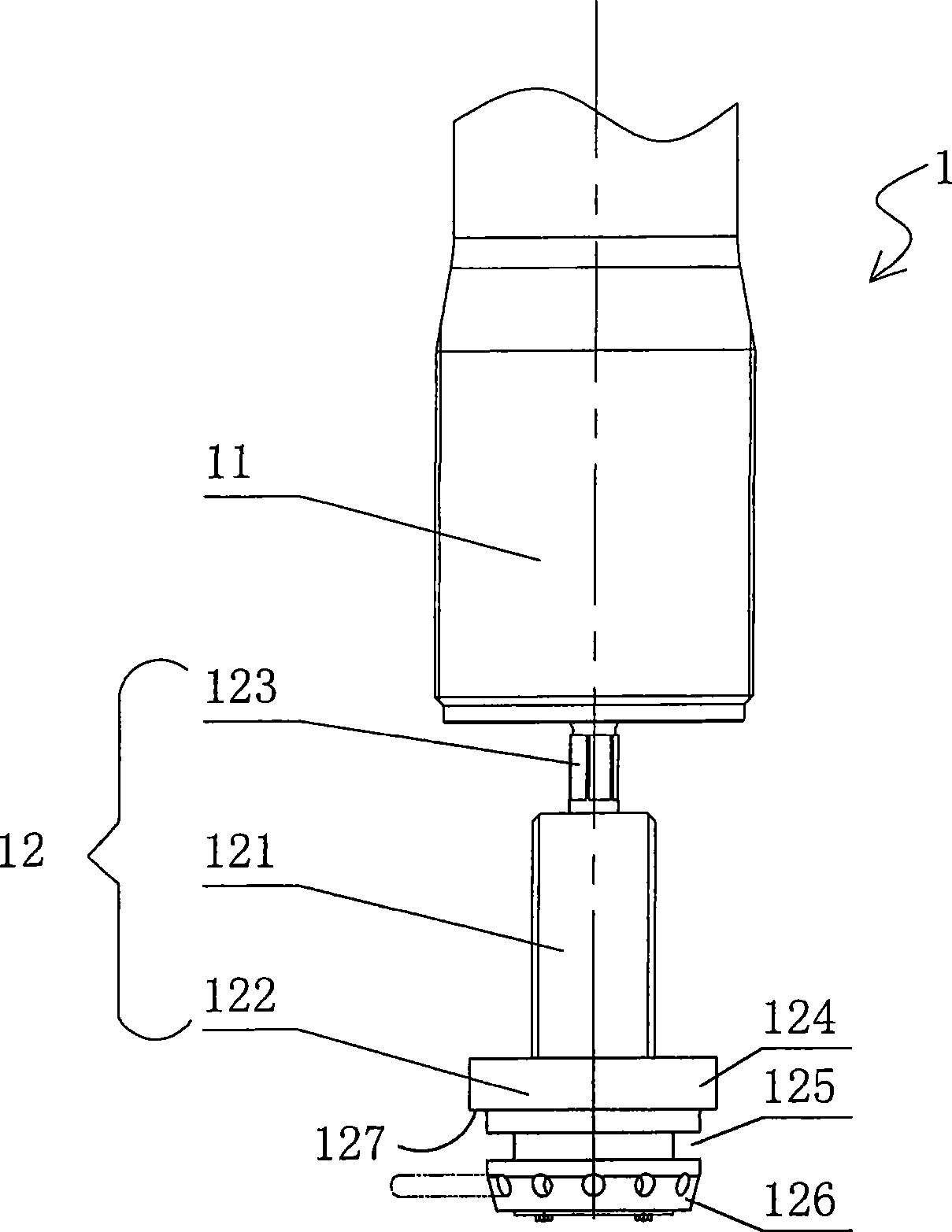

[0035] like figure 1 — Figure 4 As shown, the installation tool for the lower prestressed nut proposed by the present invention includes a rising screw 1 and a rotating table 2 . The ascending screw 1 includes a pull rod 11 and a connecting assembly 12, and the connecting assembly 12 is fixedly connected to the lower part of the pull rod 11. The turntable 2 comprises a lower prestressed nut 21 and a positioning assembly 22, the positioning assembly 22 is connected to the lower part of the lower prestressed nut 21, and the positioning assembly 22 and the lower prestressed nut 21 are fixed to each other in the circumferential direction, that is, they cannot rotate mutually; A through accommodating space 23 is longitudinally provided in the center. The ascending screw 1 is arranged in the accommodating space 23 of the turntable 2 so as to move up and down; the lower prestressing nut 21 and the pull rod 11 can be screwed together through the mutual cooperation of the connecting...

Embodiment approach 2

[0050] In this embodiment, the bearing 224 and the bearing seat 223 of Embodiment 1 are not included, but the above-mentioned guide rail is provided at the lower part of the positioning bracket, and the snap ring 222 is directly provided on the guide rail at the lower part of the positioning bracket. At this time, the positioning bracket 221 needs to have a supporting surface, so that the shoulder of the stepped matching portion 124 can push against the supporting surface for positioning.

[0051] The installation tool of this embodiment has a simple structure, reduced manufacturing cost and reduced installation time due to the lack of components such as bearings and bearing housings.

[0052] Other structures, working principles, and beneficial effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap